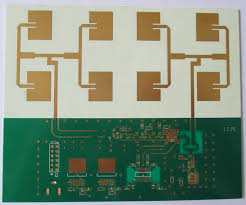

Rogers 4003C PCB Manufacturer. Microtrace Rogers PCBs, HDI Rogers PCBs, Hybrid pressing Rogers PCBs, Cavity Rogers PCBs, and Rogers package substrate manufacturing.

Offered in various configurations, RO4003C laminates utilize both 1080 and 1674 glass fabric styles with all configurations meeting the same laminate electrical performance specification. RO4003C laminates provide tight control on dielectric constant (Dk) and low loss while utilizing the same processing method as standard epoxy/glass but at a fraction of the cost of conventional microwave laminates. Unlike PTFE based microwave materials, no special through-hole treatments or handling procedures are required.

RO4003C materials are non-brominated and are not UL 94 V-0 rated. For applications or designs requiring a UL 94 V-0 flame rating, RO4835™ and RO4350B™ laminates do meet this requirement.

Features

- Dk of 3.38 +/- 0.05

- Dissipation factor of 0.0027 at 10 GHz

- Low Z-axis coefficient of thermal expansion at 46 ppm/°C

Benefits

- Ideal for multi-layer board (MLB) constructions

- Processes like FR-4 at lower fabrication cost

- Designed for performance sensitive, high volume applications

- Competitively priced

What is Rogers 4003C PCB?

Rogers 4003C PCB stands out as a high-performance Package Substrate crafted by Rogers Company, featuring specialized materials that excel in both dielectric and mechanical properties. Renowned for its remarkable dielectric characteristics, this material ensures the steadfastness and dependability of signal transmission, particularly crucial in high-frequency environments. This makes Rogers 4003C PCB a preferred material across various industries.

Notably, the stable mechanical properties exhibited by Rogers 4003C PCB contribute to its reliability under diverse environmental and operational conditions. This stability is pivotal in ensuring the prolonged and dependable functioning of electronic equipment.

Functioning as a crucial Package Substrate, Rogers 4003C PCB assumes a pivotal role in the manufacturing of electronic equipment. Its widespread application spans communication equipment, radio frequency modules, medical devices, and more, providing a robust and efficient circuit foundation for these technologies.

In essence, Rogers 4003C PCB transcends its role as a mere circuit board material; it emerges as a cornerstone technology, offering robust performance support for advanced electronic devices. The combination of outstanding dielectric properties, high-frequency performance, and stable mechanical characteristics establishes it as a primary choice for electronic engineers engaged in the design of cutting-edge electronic equipment.

What are the advantages of Rogers 4003C PCB?

As a high-performance Package Substrate, Rogers 4003C PCB shows unique advantages in electronic design compared with other materials, mainly reflected in its high integration, compact size and excellent heat dissipation performance.

Highly integrated design

The high level of integration of the Rogers 4003C PCB is one of its striking features. This material allows engineers to implement more functions in a limited space, making the design of electronic devices more streamlined and efficient. Its excellent signal transmission performance makes Rogers 4003C PCB perform excellently in high-frequency applications, providing a reliable foundation for the integration of complex circuits.

Compact size design

The popularity of Rogers 4003C PCB can be attributed to its compact size, a key factor in the widespread adoption of this circuit board. Its smaller footprint, in comparison to conventional circuit boards, plays a pivotal role in achieving lightweight and miniaturized designs for contemporary electronic devices. This streamlined and compact design distinguishes the Rogers 4003C PCB, making it particularly advantageous for applications with limited space, thereby enhancing flexibility in product design.

Excellent cooling performance

Rogers 4003C PCB has excellent thermal performance, which is particularly critical in the design of high-power electronic equipment. Its material properties can effectively conduct and disperse heat, reduce the operating temperature of the equipment, and improve the stability and life of electronic components. This makes Rogers 4003C PCB the first choice for heat-sensitive applications, such as high-performance computers, communication base stations, etc.

Improve design flexibility

The exceptional characteristics of Rogers 4003C PCB empower engineers with enhanced design flexibility. This capability not only facilitates the integration of intricate functionalities into compact devices but also aligns well with the market’s growing demand for high-performance and miniaturized products. The unique features of Rogers 4003C PCB serve as a catalyst for innovation among designers, enabling them to spearhead technological advancements in the electronics domain.

In essence, the benefits of Rogers 4003C PCB, such as high integration, compact form factor, and outstanding heat dissipation performance, position it as a highly recommended and optimal choice in electronic design. Its application not only elevates the performance and reliability of electronic products but also propels continuous innovation and the evolution of electronic technology.

Why choose Rogers 4003C PCB?

Rogers 4003C PCB stands out in the realm of electronic engineering due to its exceptional performance in high-frequency settings. It surpasses conventional circuit boards by virtue of its distinctive performance characteristics, making it a preferred choice across various industries. The unique attributes of Rogers 4003C PCB not only cater to a wide range of applications but also serve as a robust foundation for enhancing the overall performance of electronic devices.

Excellent performance in high frequency environment

Rogers 4003C PCB exhibits excellent characteristics in high-frequency environments, mainly due to its advanced material composition and precise manufacturing process. This material can maintain lower signal loss at higher frequencies and has a more stable dielectric constant, making it excellent in high-frequency transmission.

The selection of Rogers 4003C PCB is driven by its versatility across various specialized applications, with a primary focus on the communication field. Particularly, in high-frequency domains like 5G communication systems and satellite communication equipment, Rogers 4003C PCB stands out for its ability to facilitate superior signal transmission and stability, offering a dependable foundation for seamless data transfer.

Moreover, in radar systems, particularly within the military sector, where precision is paramount, the demand for high-performance circuit boards becomes crucial. Rogers 4003C PCB proves instrumental in this context, significantly enhancing the performance and reliability of radar systems by ensuring accurate signal transmission.

It effectively mitigates signal loss and ensures outstanding signal integrity, resulting in enhanced stability and reliability for electronic devices. This addresses common challenges encountered in high-frequency environments, making it a preferred solution for improving electronic equipment performance.

In summary, the choice of Rogers 4003C PCB is grounded in its outstanding performance in high-frequency settings and its broad applicability in communication, radar, and other specialized fields. Serving as an advanced package substrate, it not only addresses challenges associated with high-frequency operations but also opens up innovative possibilities for electronic device design, thereby contributing to the continual advancement of electronic technology.

Rogers 4003C PCB

What is the manufacturing process of Rogers 4003C PCB?

The production of Rogers 4003C PCB involves a sophisticated and intricate manufacturing process, employing advanced techniques such as lamination, cutting, and specialized impedance matching procedures. These sequential steps are essential not only for achieving consistent electrical performance but also for ensuring exceptional signal transmission efficiency.

Lamination Process: Establishing a Solid Foundation

The initial stage in crafting Rogers 4003C PCB entails the lamination process, wherein thin substrates and copper foil undergo a robust bonding procedure under high-temperature and high-pressure conditions. The critical aspect of this phase is to guarantee uniform pressure distribution, preventing irregular thickness or the formation of bubbles. This meticulous attention ensures the overall uniformity and stability of the PCB sheet.

Cutting Process: Precision Detailing

Following lamination, the PCB sheets advance to the cutting process, where they undergo precise shaping and structuring. Utilizing state-of-the-art CNC cutting equipment is imperative to achieve a high degree of accuracy in crafting circuit boards. The success of this step is paramount as it directly influences the geometry and dimensions of the final product, laying the foundation for subsequent manufacturing stages.

Impedance matching process: customized electrical performance

Rogers 4003C PCB is unique in that it uses a special impedance matching process. This step involves custom-arranging electrodes on the surface of the plate to ensure matching of electrical signals at different frequencies. This highly precise impedance matching process makes Rogers 4003C PCB the first choice for high-frequency applications because it can provide excellent signal transmission and stable electrical performance.

Key steps to ensure electrical performance

The production of Rogers 4003C PCB centers around meticulous attention to its electrical performance. Every stage is rigorously monitored to maintain the material’s dielectric constant and dissipation factor within specified parameters. This stringent control over key variables enables manufacturers to produce circuit boards that meet the exacting standards of applications with stringent electrical performance criteria.

The manufacturing process of Rogers 4003C PCB is a sophisticated and technology-intensive endeavor aimed at ensuring the final product exhibits exceptional performance and consistent signal transmission. Employing techniques such as lamination, precision cutting, and specialized impedance matching processes, the Rogers 4003C PCB emerges as a valuable asset in the realm of electronic engineering. It serves as a dependable solution for high-frequency applications, where reliability and stable signal transmission are paramount.

In what fields is it widely used?

As a high-performance Package Substrate, Rogers 4003C PCB plays a key role in electronic engineering. Its excellent performance characteristics are particularly outstanding in areas requiring high-frequency signal transmission and stable performance, covering multiple key application areas.

The Rogers 4003C PCB has gained widespread adoption in the communication industry, particularly in the context of advancing 5G technology. Its exceptional high-frequency performance and low signal loss characteristics make it an optimal choice for various applications within 5G communication equipment. This includes deployment in communication base stations, radio frequency modules, and antenna systems, where it excels in high-speed data transmission, spectrum efficiency, and signal stability.

The Rogers 4003C PCB has proven to be exceptionally robust in satellite communication systems, playing a pivotal role in ensuring reliable and efficient signal transmission. Renowned for its low signal loss and impressive signal fidelity, this PCB material has become the preferred choice for satellite communication equipment, offering stability and high performance even in challenging environmental conditions.

In the field of medical equipment, where the need for high-frequency signals and unwavering reliability is crucial, the Rogers 4003C PCB is gaining increased prominence. Its application extends to critical areas such as medical imaging equipment, laser treatment systems, and other high-frequency communication medical devices. The consistent performance of the PCB significantly contributes to the reliability and precision of vital data transmission in medical settings.

Moreover, the aerospace industry reaps substantial benefits from the application of the Rogers 4003C PCB, especially in demanding high-altitude and high-speed flight environments. The stringent requirements for electronic equipment performance and stability in aerospace applications find an optimal solution in the exceptional high-frequency performance and reliability of the Rogers 4003C PCB. It is effectively employed in radar systems, navigation equipment, and various other aerospace electronic systems, ensuring the steadfast operation of devices even under extreme conditions.

In summary, the Rogers 4003C PCB has successfully permeated various industries, including communications, satellite communications, medical, and aerospace, owing to its outstanding performance in high-frequency signal transmission and stability. Its broad application provides a reliable foundation for diverse electronic devices, contributing to technological innovation and development across these fields.

How to find Rogers 4003C PCB?

With a dedicated focus on high-performance electronic materials, they bring to the table years of experience and an outstanding reputation, offering a diverse range of top-tier PCBs, including the specialized Rogers 4003C variety that adheres to industry standards.

Additionally, specialized PCB suppliers play a pivotal role by emphasizing the delivery of a wide array of printed circuit boards, particularly those employing high-frequency materials like Rogers 4003C. Equipped with advanced production facilities and proficient technical teams, these specialized suppliers are adept at meeting diverse customer needs. Collaborating with such suppliers facilitates easy access for engineers to tailor-made Rogers 4003C PCBs that align precisely with their specific requirements.

In addition to external suppliers, our company proudly serves as a reliable source for Rogers 4003C PCBs. Committed to delivering high-quality electronic materials, we offer a one-stop solution for streamlined purchasing, ensuring product consistency and traceability across various application scenarios.

When evaluating potential Rogers 4003C PCB suppliers, beyond a company’s reputation, certain key considerations come into play:

Quality Certification:Verify that suppliers adhere to relevant quality certification standards, such as ISO 9001, to guarantee product excellence.

Lead Time:Understand the supplier’s production capacity and lead time to ensure alignment with project timelines.

Technical Support: Opt for a supplier offering professional technical support, facilitating timely assistance during the design and production phases.

By meticulously selecting suppliers based on these criteria, engineers can confidently acquire high-quality Rogers 4003C PCBs, thereby enhancing the likelihood of success in their projects. Our company eagerly anticipates the opportunity to establish a long-term partnership with you, fostering innovation and development in the electronic field collaboratively.

What is the quote for Rogers 4003C PCB?

When selecting Rogers 4003C PCB, obtaining a detailed and accurate quote is a critical step in ensuring the success of your project. This process involves many factors, among which elements such as engineering specifications, quantity and delivery time play a vital role in the quotation.

Quotations for Rogers 4003C PCB are usually customized based on the needs of the specific project. Suppliers carefully review engineering specifications to ensure that the materials provided meet the project’s design and performance requirements. This involves a detailed understanding of board dimensions, laminate construction, impedance requirements, etc. It is therefore important to ensure clear and detailed specifications for the works are provided before commencing a quote.

Another factor that affects Rogers 4003C PCB quotation is the order quantity. Generally speaking, high-volume production tends to result in more competitive prices. Suppliers will provide corresponding discounts or offers based on your order quantity, so it is crucial to clarify your production scale at the beginning of the project.

In such scenarios, the supplier might propose expedited production services, often accompanied by additional charges. Hence, when furnishing a quotation, it is imperative to clearly specify the project’s delivery date to facilitate the seamless execution of the production schedule.

There are some other key factors to note when getting a quote for Rogers 4003C PCB. One of them is the availability of materials. As a high-performance material, the supply of Rogers 4003C PCB may be affected by market fluctuations. Before quoting, it is a wise decision to understand the current market conditions, as well as the supplier’s inventory and production capabilities.

In addition, it is critical to ensure that the project’s special needs and customization requirements are communicated to suppliers. Sometimes, some special processing or impedance matching may require additional cost, but this can also ensure the required final performance.

Before concluding a quote, engineers and procurement teams need to consider all of these factors and weigh cost against performance to make an informed decision.

To sum up, getting a quote for Rogers 4003C PCB is more than simply knowing the price. It is a process of deeply understanding the project requirements and balancing the relationship between cost and performance. By carefully considering engineering specifications, quantities, lead times, and other key factors, you can ensure that the final Rogers 4003C PCB selected meets the project’s requirements while being the most competitive in terms of cost.

Frequently Asked Questions

What is Rogers 4003C PCB, and what sets it apart from other types of PCBs?

Rogers 4003C PCB is a high-performance Package Substrate manufactured using specialized materials from Rogers Corporation. Its key differentiators include outstanding dielectric properties, excellent high-frequency performance, and stable mechanical characteristics. These features make it stand out in electronic device manufacturing.

What advantages does Rogers 4003C PCB offer compared to other Package Substrates?

Rogers 4003C PCB excels in high integration, compact dimensions, and superior heat dissipation, providing designers with increased flexibility. Its unique characteristics make it an ideal choice for applications requiring advanced functionality in confined spaces.

Why should one choose Rogers 4003C PCB over traditional circuit boards?

In comparison to traditional boards, Rogers 4003C PCB stands out due to its excellent performance in high-frequency environments. It finds particular suitability in areas such as communication devices, radar systems, and RF modules, enhancing overall electronic device performance.

What is the manufacturing process for Rogers 4003C PCB?

The manufacturing process involves intricate techniques such as precise lamination, cutting, and specialized impedance matching processes. These steps ensure the final product possesses stable electrical properties and outstanding signal transmission effects.

In which fields is Rogers 4003C PCB widely applied?

Rogers 4003C PCB finds extensive application in various fields, particularly in devices requiring high-frequency signal transmission and stability. Examples include 5G communication base stations, satellite communication systems, and medical devices.

Where can one find reliable sources for Rogers 4003C PCB?

Several electronic manufacturing companies and specialized suppliers offer Rogers 4003C PCB. Ensuring access to high-quality Rogers 4003C PCB involves identifying reputable suppliers with a track record of delivering reliable products.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier