What exactly is a Rogers 4830 PCB?

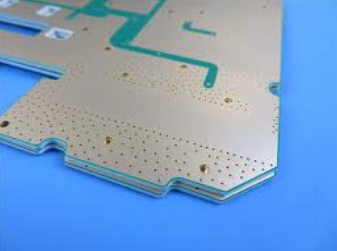

Rogers 4830 PCB Manufacture. Professional Rogers 4830 PCB manufacturer. We have a wide range of Rogers materials in stock. the PCBs were made with Rogers base materials.

RO4830 thermoset laminates are well suited for price-sensitive millimeter wave applications, such as 76-81 GHz automotive radar sensors. RO4830 laminates can be fabricated using standard FR-4 processes and are intended for the cap layer on FR-4 multi-layer board designs commonly used in 76-81 GHz automotive radar sensor PCB applications.

Features

- Dielectric constant of 3.24

- Excellent insertion loss of 2.2 db/in at 77 GHz

- UL 94 V-0 flame retardant rating

- Optimized filler, resin & glass composite system

- Reverse treated smooth LoPro® copper foil

Benefits

- Significantly resistant to oxidation

- Good laser drilling performance & consistent within sheet dielectric constant

- Reduced overall cost of PCB manufacturing versus PTFE laminate options

- Ideal for use in automotive radar sensor PCB applications

Rogers 4830 PCB, as a high-performance Package Substrate, leads a new technological trend in the field of electronic engineering. This type of PCB has become a sought-after focus among engineers and designers for its superior performance and key features.

The Rogers 4830 PCB stands out due to its distinctive combination of a high dielectric constant and a low dissipation factor. These key attributes contribute to the board’s exceptional performance in high-frequency and high-speed applications. The elevated dielectric constant promotes reliable signal transmission, ensuring stability, while the low dissipation factor minimizes energy loss during signal transmission, thereby enhancing overall efficiency.

In electronic equipment, heat management is crucial, and the thermal conductivity of this PCB ensures the stability of the equipment during high-load operation, effectively preventing problems caused by overheating.

Additionally, Rogers 4830 PCB exhibits excellent dimensional stability. In high-density circuit layouts, dimensional accuracy is critical to overall system reliability. This feature ensures PCB stability and reliability in complex environments, making it ideal for many demanding projects.

Rogers 4830 PCBs are designed to support the many aspects of electronic equipment. First of all, its excellent signal transmission performance makes it an ideal choice for high-frequency communication equipment, radar systems and other fields. In these areas, stable signal transmission is the cornerstone of the proper operation of equipment, and Rogers 4830 PCB provides a solid foundation for these equipment with its high dielectric constant and low loss factor.

Secondly, the excellent thermal conductivity of Rogers 4830 PCB provides strong support for high-power applications. In equipment that operates at high loads for long periods of time, rapid dissipation of heat is critical, and this is where this PCB excels. This makes Rogers 4830 PCB widely used in satellite communications, high-performance computers and other fields.

The Rogers 4830 PCB transcends its role as a mere circuit board, serving as a catalyst for heightened performance and increased reliability in electronic equipment. With its exceptional features and versatile support, it opens up new avenues for innovation within the realm of electronic engineering.

What are the key features of Rogers 4830 PCB?

The Rogers 4830 printed circuit board (PCB) stands out as an advanced package substrate, boasting exceptional characteristics such as a high dielectric constant, low dissipation factor, outstanding thermal conductivity, and dimensional stability. These unique attributes collectively establish it as a top-tier solution in the field of electronic engineering, particularly for applications demanding high frequencies and high-speed performance.

A standout characteristic is its elevated dielectric constant, signifying increased electrical energy storage under an electric field. This proves instrumental in high-frequency signal transmission by mitigating delays and enhancing overall system performance.

Equally compelling is its low loss factor, indicating minimal absorption of electromagnetic waves during signal transmission. This low loss factor is pivotal in preserving signal clarity and accuracy, particularly in high-frequency and high-speed scenarios.

The Rogers 4830 PCB has been engineered with enhanced capabilities, particularly excelling in thermal conductivity. In the realm of contemporary electronic devices characterized by high power density and compact designs, adept thermal management is paramount. The exceptional thermal conductivity of the Rogers 4830 PCB facilitates the efficient dissipation and expulsion of heat, thereby guaranteeing the stability of devices even when subjected to heavy loads.

Noteworthy is the dimensional stability inherent in the Rogers 4830 PCB, rendering it an optimal choice for applications demanding precise dimensions in challenging environments marked by elevated temperatures and humidity. This stability ensures unwavering performance and reliability over extended periods.

The combined synergy of these key features positions the Rogers 4830 PCB as well-suited to meet the demands of high-frequency and high-speed applications. Beyond its role in communication equipment, it finds extensive applications in radar systems, satellite communications, and various electronic engineering fields. In an industry that continually seeks enhanced performance and reliability, the Rogers 4830 PCB emerges as a leading material choice, providing engineers with a futuristic solution grounded in its unique technical advantages.

What is the process of manufacturing a Rogers 4830 PCB?

The manufacturing process of Rogers 4830 PCB is a highly complex and precision engineering involving advanced lamination technology and material handling to ensure each PCB has superior performance and reliability. Here are some key steps regarding the Rogers 4830 PCB manufacturing process:

Material preparation and screening

Before manufacturing Rogers 4830 PCB, high-quality raw materials need to be prepared first. This typically includes Rogers 4830 high-frequency material, which has special dielectric properties and thermal conductivity properties for high-frequency and high-speed applications.

Lamination technology

Lamination technology plays a pivotal role in the manufacturing of Rogers 4830 PCBs. This process involves the application of high temperature and pressure to fuse multiple layers of materials into a cohesive board. Precision in the layout and alignment of each layer is paramount to ensure that the resulting PCB structure aligns with the specified design requirements.

Cutting and processing

After lamination is completed, the PCB board needs to be precisely cut and processed. This step determines the shape and size of the final PCB to suit the specific application scenario. High-precision cutting equipment ensures consistent PCB geometry and dimensions.

Following lamination and cutting processes, the Rogers 4830 PCB undergoes a sequence of chemical treatments. These treatments encompass tasks such as eliminating residues, cleaning the surface, and applying protective layers to guarantee the PCB surface’s purity and stability.

Quality control (QC) plays a pivotal role throughout the entire manufacturing procedure. Employing cutting-edge testing equipment and technology enables manufacturers to identify and confirm the performance indicators of each PCB, ensuring compliance with design specifications and industry standards.

Terminal handling

Ultimately, the Rogers 4830 PCB may require end-use processing, including soldering, assembly, and other custom processes. This ensures that the PCB can be smoothly integrated into the final electronic device.

Through these steps, the Rogers 4830 PCB maintains its excellent performance and reliability. The precision and advancement of this manufacturing process make Rogers 4830 PCB the package substrate of choice in many high-frequency and high-speed applications.

What are the advantages of Rogers 4830 PCB over traditional circuit boards?

The superior performance of Rogers 4830 PCB provides compelling advantages over traditional circuit boards, primarily in its highly stable dielectric properties and superior thermal management.

The Rogers 4830 PCB stands out for its exceptional dielectric properties, particularly its high dielectric constant, which enhances signal transmission efficiency in high-frequency applications, ultimately elevating circuit performance. In comparison to conventional circuit boards, the Rogers 4830 PCB exhibits a low loss factor, minimizing signal energy loss and ensuring heightened signal accuracy and stability. This proves especially advantageous in applications demanding reliable signal transmission, such as communication equipment and radar systems.

Additionally, the Rogers 4830 PCB excels in thermal management, owing to its impressive thermal conductivity. This characteristic enables effective heat dissipation, leading to a reduction in the circuit’s operating temperature. As a result, system reliability and longevity are enhanced. In electronic equipment with high-power density, such as servers and power amplifiers, the thermal management capabilities of the Rogers 4830 PCB establish a robust foundation for the stable operation of the equipment.

In addition, the dimensional stability of Rogers 4830 PCB is also one of its advantages over traditional circuit boards. In high-density integrated circuit applications, changes in size can have a negative impact on circuit performance. Rogers 4830 PCB ensures circuit reliability and consistency under a variety of environmental conditions by maintaining its dimensional stability.

Overall, the advantages of Rogers 4830 PCB over traditional circuit boards are its highly stable dielectric properties, excellent thermal management performance, and dimensional stability. These advantages not only improve circuit performance but also bring more design flexibility and reliability to electronic devices in high-frequency, high-power-density applications. In the current electronic engineering environment that pursues higher performance and reliability, Rogers 4830 PCB is gradually becoming the first choice for engineers and designers.

Rogers 4830 PCB

Why Choose Rogers 4830 PCB?

As an outstanding representative of Package Substrate, Rogers 4830 PCB has attracted the attention of many engineers and designers. Its excellent performance has become the first choice in many applications for various reasons. Here’s a closer look at why Rogers 4830 PCBs are so popular in the professional world.

First, the Rogers 4830 PCB exhibits excellent performance in high frequency applications. Its high dielectric constant and low loss factor make it excellent in signal transmission and is especially suitable for areas that require stable signal transmission. This provides an ideal solution for applications such as communication equipment and radar systems that require extremely high signal stability, so engineers choose Rogers 4830 PCB to ensure reliable system performance.

Secondly, Rogers 4830 PCB has become the favorite of many designers due to its excellent thermal management performance. This makes Rogers 4830 PCB highly regarded in a range of high-temperature environment applications, such as spacecraft electronic systems, industrial control equipment, and more.

Additionally, the dimensional stability of Rogers 4830 PCB is one of the reasons why it is so popular. In modern electronic devices, compactness in size places increasing demands on design. The dimensional stability of Rogers 4830 PCB can provide reliable support in high-density integrated circuit environments, making it widely used in various miniaturized devices, such as smartphones, wearable devices, etc.

Overall, the superior performance of Rogers 4830 PCB covers many aspects such as high-frequency signal transmission, thermal management and dimensional stability, providing engineers and designers with a comprehensive solution. Its excellent performance in various application scenarios makes people flock to it. As an outstanding representative of Package Substrate, Rogers 4830 PCB not only occupies a place in the current field of electronic engineering, but also provides unlimited possibilities for future innovation.

In what areas is Rogers 4830 PCB widely used?

Rogers 4830 PCB serves as an outstanding high-performance substrate in the realm of electronics, demonstrating exceptional performance and versatility across various applications. It particularly excels in communication equipment, radar systems, and satellite communications, making it a preferred choice for its superior functionality and applicability in these fields.

Communication device

In the field of communication equipment, Rogers 4830 PCB plays a key role. Its highly stable dielectric properties and low loss factor make it ideal for wireless communications equipment. From the base station to the antenna, Rogers 4830 PCB can provide excellent signal transmission performance to ensure the accuracy and stability of data transmission. Its dimensional stability also makes it suitable for the design of miniaturized and lightweight communication equipment, meeting the requirements of modern communication technology for high integration and miniaturization.

Radar system

In radar systems, the wide application of Rogers 4830 PCB is reflected in its superior high-frequency performance and excellent signal processing capabilities. Radar systems have extremely high requirements for high-frequency signal processing, and the high dielectric constant and low loss factor of Rogers 4830 PCB make it an ideal choice for processing these complex signals. In radar antennas, signal processing units, and radar control systems, Rogers 4830 PCB can provide excellent performance to ensure stable operation of radar systems under various environmental conditions.

Satellite Communications

The field of satellite communications also has extremely high performance requirements for PCBs, especially the need to maintain stability in extreme space environments. The application of Rogers 4830 PCB in satellite communication systems is mainly reflected in its resistance to temperature changes and space radiation.

For example, in 5G communication base stations, Rogers 4830 PCB can support high-frequency, high-speed signal transmission and improve the performance of the communication system. In satellite radars, Rogers 4830 PCB can be used to manufacture high-performance RF front-ends to ensure accurate monitoring of long-distance targets by radar systems.

The extensive use of Rogers 4830 PCB across various applications, including communication equipment, radar systems, and satellite communications, underscores its outstanding performance characteristics. This preference not only highlights its remarkable capabilities in high frequency, high speed, and high stability but also plays a pivotal role in driving technological advancements and progress within these domains. Engineers and designers consistently opt for Rogers 4830 PCB as their primary choice, empowering electronic professionals with enhanced possibilities for innovation in their projects.

How to find a high quality Rogers 4830 PCB?

When seeking a high-quality Rogers 4830 PCB, the selection of a reliable source is paramount and directly correlates with project success and device performance. Consider the following guidelines to identify a top-tier Rogers 4830 PCB that aligns with your specifications.

Technical Support: Assess whether the manufacturer offers robust technical support. Exceptional Rogers 4830 PCBs necessitate more than just cutting-edge manufacturing equipment; they also require the manufacturer’s technical expertise to ensure the product meets the specific requirements of your application.

Factory Tour: If possible, consider visiting the manufacturer’s production facility in person. Intuitive understanding of the production process and equipment status allows for a more comprehensive assessment of its manufacturing level and quality management standards.

Supplier reputation: Choose to work with suppliers that have established a good reputation. Understand the supplier’s reliability and service levels by referring to industry recommendations, customer reviews, and past transaction records.

Implementing a consistent quality review system is crucial when engaging with suppliers. It is imperative to confirm their willingness to adhere to international quality standards and furnish comprehensive production process and quality inspection reports. Transparent and timely communication is equally vital, enabling continuous monitoring of production advancements, quality control procedures, and potential setbacks. This proactive approach facilitates swift issue resolution and ensures timely delivery of products.

By taking into account manufacturer and supplier reputation, technical support, factory conditions, and transparent communication, you can more reliably obtain standards-compliant products to ensure a successful project. When choosing a partner, careful and comprehensive consideration will bring stability and success to your electronic engineering project.

What should I pay attention to when quoting Rogers 4830 PCB?

When getting a quote for a Rogers 4830 PCB, there are several factors that need to be carefully considered to ensure you select the best product. Here are some key factors to pay special attention to:

Material quality and supplier reputation

The performance of Rogers 4830 PCB is intricately linked to the quality of its materials. Consequently, when selecting a supplier, it is crucial to verify the use of premium-grade, industry-standard materials. Evaluating the supplier’s credibility by examining its standing in the PCB industry and reviewing customer feedback is a critical measure to guarantee the quality of materials.

Manufacturing process and technical capabilities

Consideration of the supplier’s manufacturing processes and technical capabilities is critical to ensuring product consistency and quality. High-level manufacturing processes ensure that PCBs perform as expected, with reliability and stability.

PCB dimensions and layers

Make sure the PCB size and layering match the project needs. Different applications may require PCBs with different specifications, and the choice of hierarchy is closely related to circuit complexity and performance requirements. Clarifying these requirements before quoting can help avoid unnecessary problems later.

Quantity and delivery lead time

Clarity on order quantities and lead times is critical to project planning and progress. Communicate production capabilities and delivery times with suppliers to ensure required quantities of product are available in the time required for the project.

Technical support and after-sales service

Selecting a supplier capable of offering robust technical support and effective after-sales service is crucial for obtaining timely assistance throughout the project implementation. This encompasses receiving technical guidance during the design phase, as well as support throughout the manufacturing and testing processes.

Cost and performance balance

Although cost is an important factor to consider, performance should not be sacrificed. Find the most cost-effective solution to ensure you meet quality and performance needs while maintaining reasonable cost levels.

Ensure Rogers 4830 PCB complies with appropriate industry standards and certification requirements, such as IPC standards. This helps ensure product quality and reliability and is a must-have for many industry applications.

When considering the above factors, full communication and consultation with suppliers is critical. By clarifying project requirements, understanding product specifications, and obtaining detailed quotation information, we can provide strong support in selecting the appropriate Rogers 4830 PCB and ensure the successful implementation of the project.

What are the common problems with Rogers 4830 PCB?

Rogers 4830 PCB, being an innovative Package Substrate, often sparks curiosity among engineers and designers. Let’s delve into some common questions and provide insightful answers to demystify the aspects surrounding Rogers 4830 PCB.

How is Rogers 4830 PCB manufactured, and what are the critical steps in the process?

The manufacturing process of Rogers 4830 PCB involves advanced lamination techniques and material treatments. Precision machining and stringent quality control ensure each PCB’s performance and reliability, including key steps like…

In what applications does Rogers 4830 PCB find widespread use?

Rogers 4830 PCB finds applications across various fields such as communication devices, radar systems, and satellite communication. Understanding its diverse applications provides insights into the breadth of its usage.

What advantages does Rogers 4830 PCB offer over traditional circuit boards?

Compared to conventional boards, Rogers 4830 PCB provides heightened stability in dielectric performance and superior thermal management, delivering notable advantages in precision signal transmission and support for high-density integration.

What factors should be considered when obtaining a quote for Rogers 4830 PCB?

When seeking quotes for Rogers 4830 PCB, considerations should encompass factors like material costs, manufacturing complexity, and volume requirements. A comprehensive understanding of these aspects ensures accurate and fair pricing.

What common misconceptions surround Rogers 4830 PCB?

Addressing misconceptions is crucial. Common misunderstandings may include assumptions about its compatibility, limitations, or applicability in certain environments. Dispelling these misconceptions contributes to a clearer understanding of the technology.

How does Rogers 4830 PCB contribute to innovation in electronic engineering projects?

Rogers 4830 PCB, as a representative of advanced Package Substrates, contributes significantly to innovation in electronic engineering. Understanding its role in pushing the boundaries of design and performance enhances its value in various projects.

How does Rogers 4830 PCB impact the overall performance of electronic devices?

The impact of Rogers 4830 PCB on overall device performance is substantial. Its influence on signal integrity, thermal management, and dimensional stability collectively contribute to enhanced reliability and efficiency in electronic devices.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier