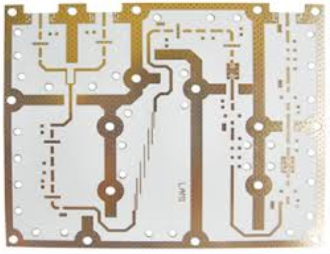

Rogers 4360G2 PCB Vender. We offer Rogers PCBs from 2 layer to 30 layers. HDI Rogers PCBs. Mixed media Rogers PCBs. Cavity Rogers PCBs. and other types Rogers PCB boards.

RO4360G2 laminates are the first high dielectric constant (Dk) thermoset laminate that can be processed similar to FR-4. These materials are lead-free process capable and offer better rigidity for improved processability in multi-layer board constructions, while reducing material and fabrication costs. RO4360G2 laminates can be paired with RO4400™ series prepreg and lower-Dk RO4000® laminate in multi-layer designs.

Features

- Dk of 6.15 +/- 0.15

- Low dissipation factor of 0.0038 at 10 GHz

- High thermal conductivity of 0.75 W/(m-K)

- Low Z-axis coefficient of thermal expansion at 28 ppm/°C

- High Tg greater than 280 °C TMA

Benefits

- Automated assembly compatible

- Plated through-hole reliability

- Environmentally friendly – lead free process compatible

- Efficient supply chain and short lead times makes for cost effective material option

What is Rogers 4360G2 PCB?

The Rogers 4360G2 PCB stands as a pinnacle in advanced Package Substrate technology, transforming the electronic device design landscape. This cutting-edge PCB not only boasts an appealing aesthetic but also exhibits outstanding characteristics in the realm of high-performance electronics.

Crafted with state-of-the-art materials and processes, the Rogers 4360G2 PCB presents electronic engineers with an inventive solution for Package Substrate. It goes beyond the traditional concept of a circuit board, marking a technological breakthrough by seamlessly integrating highly complex electronic components into a more compact and efficient form.

In the realm of electronic equipment, the Rogers 4360G2 PCB assumes a pivotal role, particularly in scenarios demanding superior signal transmission and stability. Its outstanding electrical properties contribute to exceptional performance in high-frequency applications, ensuring the steadfast operation of electronic devices.

In comparison to traditional PCBs, the Rogers 4360G2 PCB boasts a higher degree of integration, emerging as an indispensable element in modern electronic devices. Against the backdrop of the prevailing trends toward miniaturization and lightweight design, the compact and efficient layout of the Rogers 4360G2 PCB not only conserves space but also enhances flexibility in product design.

Rogers 4360G2 PCB is widely used in smartphones, computers, communication equipment and other fields. Its advanced performance enables the device to meet the continuous challenges of size and weight of modern electronic devices while maintaining efficient performance.

Overall, Rogers 4360G2 PCB represents the pinnacle of Package Substrate technology. It provides electronic engineers with an unprecedented solution by providing excellent electrical performance, highly integrated design, and wide application in multiple fields. In the future, with the continuous advancement of technology, Rogers 4360G2 PCB will continue to lead the development direction of advanced electronic equipment.

What type of Rogers 4360G2 PCB is it?

Rogers 4360G2 PCB, an advanced Package Substrate technology, is distinguished by its exceptional electrical performance and reliability, catering to diverse design needs across electronic devices. Before exploring its various types, it is crucial to grasp the fundamental concepts of Rogers 4360G2 PCB.

Functioning as a high-performance Package Substrate, Rogers 4360G2 PCB excels in signal transmission, stability, and size optimization. Let’s delve into the distinct types that characterize this technology.

This type proves invaluable in electronic devices requiring heightened integration and reduced size. The BGA packaging form facilitates the accommodation of more pins within a relatively compact area, thereby offering additional connection points.

CSP (Chip Scale Package): CSP, a chip size package, is designed to minimize package size while maintaining close alignment with chip dimensions. In Rogers 4360G2 PCB, CSP finds application in scenarios with stringent size and weight requirements, such as portable devices and embedded systems.

The variety of Rogers 4360G2 PCB types enables it to meet a wide range of electronic device design needs. BGA is commonly used in high-performance computers, servers and communications equipment, while CSP is widely used in mobile devices, wireless sensors and other size-critical applications.

The diverse types of Rogers 4360G2 PCB provide engineers with a wealth of choices to meet the design needs of different electronic devices. Whether you are pursuing high-performance servers or projects with strict size requirements for portable devices, the diversity of Rogers 4360G2 PCBs is driving innovation and advancement in electronic design.

What are the advantages of Rogers 4360G2 PCB?

In today’s sophisticated electronics landscape, Rogers 4360G2 PCB stands out as an advanced Package Substrate technology, increasingly favored for high-end electronic products owing to its exceptional performance in electrical characteristics, heat dissipation, and size optimization. The following highlights the prominent advantages of Rogers 4360G2 PCB over traditional counterparts.

Outstanding Electrical Performance

Rogers 4360G2 PCB showcases remarkable electrical performance, leveraging high-performance materials that excel in signal transmission. This translates to reduced signal loss and enhanced data transmission stability.

Superior Cooling Capabilities

In comparison to conventional PCBs, Rogers 4360G2 PCB demonstrates significant advantages in heat dissipation. Its material exhibits excellent thermal conductivity, efficiently dissipating and removing the heat generated by electronic devices. This not only contributes to improved operational efficiency but also lowers the overall system’s operating temperature. This is particularly beneficial in scenarios with high load and stringent performance requirements, extending the equipment’s service life.

Size-optimized design

Rogers 4360G2 PCB focuses on size optimization in design, achieving a smaller board area. This makes it easier to integrate more functions and components in a limited space, providing the possibility for miniaturization and lightweighting of electronic products. This advantage is particularly important in the current consumer electronics market that pursues portability and compact design, making Rogers 4360G2 PCB an ideal choice for designers pursuing a balance of innovation and performance.

Due to its excellent performance in electrical performance, thermal performance and size optimization, Rogers 4360G2 PCB has become the first choice for high-end electronic products.

Manufacturers across various industries, whether producing smartphones, computers, or communication equipment, consistently opt for Rogers 4360G2 PCB to ensure their products stand out in the fiercely competitive market. Renowned for its unparalleled reliability and stability, this PCB proves to be a pivotal element in meeting the stringent demands of users, establishing a robust foundation for the success of high-end electronic devices.

In essence, Rogers 4360G2 PCB distinguishes itself with outstanding electrical performance, efficient heat dissipation capabilities, and a well-optimized design for size. Beyond catering to the current requirements of electronic equipment for high-performance package substrates, it also provides robust support for future technological advancements. Striking a balance between exceptional performance and innovative design, Rogers 4360G2 PCB consistently charts the course for the evolution of electronic engineering, setting the standard for excellence in the industry.

Rogers 4360G2 PCB

Why Choose Rogers 4360G2 PCB?

In today’s electronics manufacturing world, selecting the appropriate Package Substrate is critical to product performance and reliability. The Rogers 4360G2 PCB stands out among the many options with its unique features. Why is it so eye-catching? Here are its advantages over other boards and why choosing the Rogers 4360G2 PCB is more attractive among the many options.

Excellent electrical performance

The Rogers 4360G2 PCB stands out with its utilization of high-performance materials, elevating its signal transmission capabilities above traditional circuit boards. Specifically engineered for high-frequency applications, it boasts lower signal loss and enhanced signal transmission speed. Notably, the PCB addresses the critical issue of heat dissipation in contemporary electronic devices. By incorporating advanced material optimization and thoughtful structural design, it excels in heat dissipation, ensuring optimal performance and stability in equipment operation.

Size optimization and high integration

The design of Rogers 4360G2 PCB focuses on compact size and high integration, making it particularly suitable for miniaturized and lightweight electronic equipment. Compared with traditional circuit boards, it can achieve more functional integration in a limited space, bringing greater flexibility to product design.

Stability and reliability

The Rogers 4360G2 PCB stands as a testament to the pivotal importance of stability and reliability in the realm of electronics, setting the stage for the success of products. Through sophisticated manufacturing processes and the careful selection of premium materials, this PCB variant assures steadfast stability across diverse environmental conditions. Its commitment to dependable performance significantly diminishes the likelihood of failures.

Designed to cater to a broad spectrum of applications, the Rogers 4360G2 PCB excels not only in the domain of communication equipment but also finds widespread utility in various fields, including smartphones and computers. Its adaptability proves to be a key asset, allowing it to seamlessly meet the distinctive requirements of different industries.

The manufacturing of Rogers 4360G2 PCB involves advanced processes and technologies, including advanced lamination technology and materials engineering. This allows it to maintain a leading position in technology among similar products and provide customers with advanced solutions.

To sum up, the advantages of Rogers 4360G2 PCB over other circuit boards are obvious. Its excellent electrical properties, excellent heat dissipation performance, size optimization and high integration, stability and reliability, as well as a wide range of application fields, make it more attractive among many choices. For electronic equipment manufacturers pursuing excellent performance and reliability, choosing Rogers 4360G2 PCB is an important step in promoting technological innovation and product competitiveness.

What is the manufacturing process of Rogers 4360G2 PCB?

The production of the Rogers 4360G2 PCB involves a meticulously orchestrated series of steps aimed at achieving superior quality and reliability in the final product. This high-performance Package Substrate undergoes a precise manufacturing process, encompassing key stages to ensure optimal results.

Material preparation

Manufacturing of the Rogers 4360G2 PCB begins with the materials preparation phase. High-performance substrates often use fiberglass reinforcements to ensure high strength and excellent electrical performance. In addition, resin and copper foil are also key materials in the manufacturing process.

Design and layout

In the initial phases of the manufacturing process, the focus is on PCB design and layout, which involves transforming a circuit diagram into a PCB configuration, ensuring precise connection and strategic placement of circuit components. Specifically crafted for high-frequency signal transmission and stability, the Rogers 4360G2 PCB prioritizes stringent requirements.

Graphical Manufacturing Process

Employing cutting-edge photoimaging technology, the board undergoes a meticulous process. Initially, a photosensitive coating is applied to the board’s surface. Subsequently, a photomask is employed to selectively expose the photosensitive layer, forming a precise circuit pattern. This crucial step is instrumental in guaranteeing the accuracy and reliability of the circuit configuration.

Copper foil peeling

After the circuit pattern is formed, the copper foil stripping process is performed. This involves using chemical methods to remove excess copper foil not covered by the photosensitive layer, leaving the desired circuit pattern.

Copper foil deposition

Next, copper foil deposition is performed, chemically adding layers of copper in defined areas to enhance conductivity and connectivity.

The production of Rogers 4360G2 PCB involves a meticulous manufacturing process that prioritizes material selection, precise circuit design, and manufacturing precision. The process begins with the deposition of copper foil, followed by the application of a solder mask to safeguard the circuit and define the soldering area. Subsequent copper plating enhances mechanical strength by adding a protective copper layer to the circuit pattern.

As the manufacturing progresses, a crucial step involves the application of rubbing, where labels, logos, and necessary text are printed onto the PCB surface. This step adds essential information and branding to the PCB. The final phase of the process entails rigorous tests and inspections to verify that the PCB adheres to design specifications and meets high-quality standards.

This comprehensive manufacturing approach ensures not only the high performance and stability of the final Rogers 4360G2 PCB but also its wide applicability in the electronic field. Delving into the intricacies of this manufacturing process provides valuable insights into how the exceptional quality of the Rogers 4360G2 PCB is consistently maintained.

In what areas is Rogers 4360G2 PCB widely used?

Rogers 4360G2 PCB, as an advanced Package Substrate technology, is extensively utilized across diverse sectors, including smartphones, computers, and communication equipment. Its exceptional performance and features contribute significantly to the advancement of these industries.

In the realm of smartphones, the compact and lightweight design of Rogers 4360G2 PCB facilitates the creation of thinner mobile devices while ensuring efficient and stable operation. The superior electrical performance of this technology enables the densely packed arrangement of electronic components within the mobile phone, leading to enhanced integration. This not only contributes to improved phone performance but also provides designers with greater flexibility to craft visually appealing designs.

In the computer sector, Rogers 4360G2 PCB plays a pivotal role by ensuring high-performance characteristics that enable efficient communication among various computer components. It effectively minimizes signal loss, thereby enhancing the overall stability and reliability of computer systems. In comparison to traditional PCBs, the advanced features of Rogers 4360G2 PCB result in faster data transmission speeds, creating a more robust and stable working environment for computers.

In the field of communication equipment, Rogers 4360G2 PCB excels in high-frequency signal transmission. Its excellent signal transmission performance ensures efficient communication of communication equipment and strongly supports the development of modern communication technology. This is critical to meeting user demands for fast, reliable connections to communications devices.

Overall, the wide application of Rogers 4360G2 PCB in these fields not only promotes technological progress, but also provides a solid foundation for the innovation of electronic products. Its miniaturization, lightweight design and excellent electrical performance enable devices such as smartphones, computers and communication equipment to maintain efficient and stable operation while meeting users’ constant pursuit of portability and performance. Therefore, Rogers 4360G2 PCB is gradually becoming an indispensable key technology in the electronic field.

Where to find Rogers 4360G2 PCB?

Choosing a reliable supplier for a high-quality Rogers 4360G2 PCB is essential, and it requires careful consideration of various factors to ensure the product’s reliability. To make an informed decision when buying a Rogers 4360G2 PCB, here are some recommendations to keep in mind.

Manufacturer’s official website: The most direct way is to obtain information through the manufacturer’s official website of Rogers 4360G2 PCB. Product specifications, technical details and contact details are usually provided here.

Electronic Components Distributors: Working with a reputable electronic components distributor is a quick way to get Rogers 4360G2 PCB. These distributors usually have extensive inventory and provide prompt logistics services.

Attending industry exhibitions and conferences in the electronics sector offers a unique opportunity to directly engage with multiple suppliers, gaining insights into their products and technologies. Additionally, online electronic markets like Digi-Key and Mouser present a diverse range of electronic components, including the Rogers 4360G2 PCB, with vendor reviews and user feedback aiding in vendor credibility assessment.

When choosing a supplier, it is essential to prioritize the verification of pertinent quality certifications, such as ISO 9001, to instill confidence in their production processes and product quality. The supplier’s experience and reputation play a pivotal role; selecting one with a well-established track record supported by customer reviews, industry reports, and case studies is imperative.

Evaluate the availability of comprehensive technical support services from the supplier, as this will be instrumental in addressing issues and optimizing performance during the purchase and use phases. Assess the supplier’s delivery capabilities to ensure they align with your project’s time requirements, recognizing the critical importance of timely delivery for project success.

Cost-effectiveness is a vital consideration, balancing quality, service, and price to select a supplier that aligns best with your needs. Our commitment is to provide a high-quality Rogers 4360G2 PCB, ensuring a reliable foundation for your project. At our company, we guarantee quality products and professional service, contributing to the overall success of your project.

What is the quote for Rogers 4360G2 PCB?

When seeking a quote for a Rogers 4360G2 PCB, in addition to focusing on price factors, there are a number of factors to consider to ensure you select the right supplier and ensure product reliability and service levels. Here are some key factors:

Timely delivery is critical to project progress. Understand your supplier’s lead times and assess their flexibility in responding to urgent needs and change requests. This helps ensure projects stay on track and avoid production disruptions.

The quality of technical support and after-sales service offered by a supplier plays a crucial role in the selection process. A reliable supplier is capable of offering assistance throughout the product usage, addressing potential issues, and ensuring the overall success of the project.

The demand and ordering frequency during the mass production stage are also factors that affect the quotation. Some suppliers may offer more competitive prices on large-volume orders but may not be flexible enough on small-volume orders.

A supplier with a good reputation and history is more likely to provide a high-quality Rogers 4360G2 PCB. Review the vendor’s customer reviews and history to learn about their reputation in the industry.

When requesting a quotation for a Rogers 4360G2 PCB, it is essential to take into account various factors beyond mere pricing. Prioritize selecting a dependable supplier to guarantee the acquisition of a top-notch and high-performance Rogers 4360G2 PCB. This decision lays a robust groundwork for the success of your project.

Frequently Asked Questions

What distinguishes Rogers 4360G2 PCB from traditional PCBs?

Rogers 4360G2 PCB stands out due to its advanced materials and superior performance. It is tailored for applications with higher demands on signal transmission and stability compared to traditional PCBs.

How does Rogers 4360G2 perform in high-frequency applications?

Rogers 4360G2 excels in high-frequency applications, maintaining stable signal transmission and lower signal loss. Its design and materials make it particularly suitable for scenarios requiring precise and reliable signal integrity.

What types of Rogers 4360G2 PCB are available?

Rogers 4360G2 PCB comes in various types, including Ball Grid Array (BGA) and Chip Scale Package (CSP). These types cater to diverse design requirements across different electronic devices.

In which industries is Rogers 4360G2 PCB widely applied?

Rogers 4360G2 PCB finds extensive applications in industries such as smartphones, computers, and communication devices. Its advanced performance contributes to the miniaturization and lightweight design of these devices while ensuring efficient and stable operation.

How is the manufacturing process of Rogers 4360G2 PCB carried out?

The manufacturing process of Rogers 4360G2 PCB involves advanced techniques and processes. It includes the production steps for both the motherboard and substrate, ensuring the final product’s high quality and reliability.

What factors influence the pricing of Rogers 4360G2 PCB?

The pricing of Rogers 4360G2 PCB is influenced by factors such as specifications, quantity, and the chosen supplier. When seeking quotes, it’s essential to consider these factors alongside the supplier’s reputation and service.

Why should one choose Rogers 4360G2 PCB over other circuit boards?

Rogers 4360G2 PCB offers distinct advantages over traditional circuit boards, including superior electrical performance, efficient heat dissipation, and optimized size. These qualities make it a preferred choice for high-end electronic products.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier