What is Rogers 4835 PCB?

Rogers 4835 PCB Manufacturing. Rogers series and high frequency PCB supplier. low loss material, Dielectric constant (Dk) of 3.48 +/- .05, Dissipation factor of 0.0037 at 10 GHz.

RO4835 laminates are a low loss material that offer low cost circuit fabrication, compatible with standard epoxy/glass (FR-4) processes. These laminates are available with Rogers proprietary LoPro® Reverse treated copper foil, ideal for applications requiring low insertion loss.

Features

- RoHS compliant for applications requiring UL 94 V-0

- IPC-4103 compliant

- Dielectric constant (Dk) of 3.48 +/- .05

- Dissipation factor of 0.0037 at 10 GHz

Benefits

- Ten times improved oxidation resistance, compared to traditional thermoset laminates

- Superior high frequency application compatibility due to excellent electrical performance

- No blistering or delamination

- Reliable Plated through Hole (PTH) construction

The Rogers 4835 PCB, serving as a fundamental element in advanced PCB design, has established its presence in electronic design due to its exceptional performance and high-frequency capabilities. Beyond being a mere substrate for the circuit board, it functions as a vital component for mounting and connecting electronic elements, ensuring optimal signal integrity and device reliability.

Specifically engineered for high-frequency applications, the Rogers 4835 PCB stands out in contemporary electronic designs owing to its outstanding performance. This laminate not only acts as a robust support for the circuitry but also plays a crucial role in enhancing the stability and reliability of high-frequency electronic equipment, thanks to its superior electrical properties.

Rogers 4835 PCB is a laminate designed for high-frequency applications, and its outstanding performance makes it attractive in modern electronic designs. This laminate provides superior stability and reliability for high-frequency electronic equipment through excellent electrical properties.

As a support for electronic components, Rogers 4835 PCB effectively carries and fixes various components through its special materials and structure. This reliable support not only helps improve the mechanical strength of the circuit, but also ensures stable connections between components to maximize device performance.

The design of Rogers 4835 PCB focuses on signal integrity and ensures more stable signal transmission on the circuit board by reducing losses during signal transmission. Its excellent reliability ensures the stable operation of electronic devices in different environments and working conditions, providing users with an excellent user experience.

In high frequency electronics design, choosing the right laminate is critical. Rogers 4835 PCB is an ideal choice for engineers through its excellent high frequency characteristics. Its low dielectric constant and low loss tangent angle make it excellent in high-frequency applications, meeting demanding requirements for signal quality and stability.

As electronic design continues to move forward, Rogers 4835 PCB is a leader in future innovation. Its evolving design and material technologies make it suitable for increasingly complex and high-performance electronic devices, opening up new design possibilities for engineers.

Overall, Rogers 4835 PCB is not only the core of advanced PCB design, but also an innovative star in the field of electronic design. Its superior performance and high-frequency characteristics provide engineers with a reliable tool to help them reach new heights in high-frequency electronic design. When you choose Rogers 4835 PCB, you choose a leader in innovation, reliability and future electronic design.

What types of Rogers 4835 laminates are there?

In the contemporary landscape of advanced electronics design, Rogers 4835 laminate stands out as a widely esteemed material renowned for its exceptional performance and adaptability. This outstanding laminate comes in various types, ranging from standard laminates to high-frequency variants, offering a plethora of options to fuel innovation in electronic devices. Explore the diverse facets of Rogers 4835 laminate, each tailored to meet specific requirements and elevate the capabilities of electronic components.

Standard laminate

Rogers 4835’s standard laminate provides electrical engineers with a solid foundation. This type of laminate is widely used in general electronics design, providing reliable performance and stable electrical connections to a variety of devices. Its superior dielectric constant and low loss characteristics make it ideal for many applications.

High frequency variant

The high-frequency variant of the Rogers 4835 is at the forefront of technological innovation. These laminates shine in designs with more stringent frequency requirements. Its unique material composition and excellent high-frequency characteristics enable it to process faster and more complex signals, providing an ideal solution for radio frequency (RF) and microwave applications.

Provision of unique features

Each Rogers 4835 laminate offers unique properties to meet specific design requirements and application scenarios. From standard laminates that offer greater mechanical strength to high-frequency variants with superior high-frequency performance, the versatility of Rogers 4835 provides electronic engineers with a wide range of options.

Meet specific design requirements

The variety of laminates available serves not only to advance technological innovation but also to fulfill diverse design needs. For instance, in designs necessitating a heightened signal-to-noise ratio and reduced transmission losses, opting for a high-frequency variant may prove optimal. Conversely, for applications where mechanical strength is paramount, standard laminates may be the more appropriate choice.

Respond to different application scenarios

Whether it is communication equipment, medical equipment or aerospace technology, the diversity of Rogers 4835 allows it to flexibly respond to different application scenarios. This adaptability has made Rogers 4835 the material of choice across multiple industries, driving the development of electronic design.

Rogers 4835 laminate emerges as an invaluable asset in the dynamic landscape of evolving electronic equipment. This exceptional material empowers engineers with a robust toolkit for both pioneering product designs and the enhancement of existing equipment. The careful selection of the specific variant of Rogers 4835 laminate is a pivotal decision, crucial for the success of any project.

Within this captivating exploration, Rogers 4835 laminate unravels a realm of boundless possibilities for electronic engineers, showcasing its unrivaled versatility and superior performance. Whether applied in everyday use or specialized domains, the diverse range of Rogers 4835 laminates stands poised to spearhead the future of electronic design.

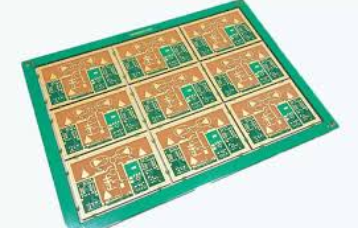

Rogers 4835 PCB

What are the advantages of Rogers 4835 PCB?

Rogers 4835 PCB stands out in high-frequency electronic design, showcasing exceptional electrical performance, minimal signal loss, and superior thermal stability. These qualities position it as the optimal choice for high-frequency applications, playing a crucial role in modern electronic engineering. This analysis delves into the distinctive advantages of Rogers 4835 PCB, emphasizing its unparalleled attributes that contribute to its prominence in the field.

Rogers 4835 PCB stands out for its outstanding electrical performance. Its high frequency response and low loss make it ideal for processing high frequency signals. For applications requiring stringent signal integrity, such as communications equipment and radio frequency circuits, the electrical performance of Rogers 4835 can provide stable and reliable performance for the system.

In high-frequency applications, signal transmission losses are critical to system performance. Rogers 4835 PCB effectively reduces energy loss during signal transmission through its low signal loss characteristics. This not only helps improve signal quality, but also supports signal transmission over longer distances, providing important advantages for critical applications such as communications and radar systems.

Rogers 4835 PCB is renowned for its exceptional thermal stability, making it a standout choice for electronic devices operating in high-temperature environments. The material’s impressive thermal properties enable consistent performance across a broad temperature range, establishing a reliable working environment for diverse applications.

Given these advantages, Rogers 4835 PCB emerges as the optimal solution for high-frequency applications. In critical fields such as wireless communications, satellite communications, radar systems, and high-frequency radio frequency circuits, where the processing of complex signals and maintaining stability are paramount, Rogers 4835 PCB has rightfully become the preferred choice due to its outstanding performance.

Its advantages not only provide technical convenience for modern electronic engineers, but also bring new possibilities to high-frequency electronic design. When you choose Rogers 4835 PCB, you choose superior performance and reliability, ensuring that your electronic system reaches its optimal level in high-frequency environments.

Why choose Rogers 4835 over other laminates?

In the rapidly evolving field of electronics design and manufacturing, the careful selection of laminates plays a crucial role in ensuring optimal performance, particularly in high-frequency applications. Among the diverse range of choices, Rogers 4835 PCB stands out as a preferred option for engineers, attributed to its exceptional performance in high-frequency environments, superior signal integrity, and versatility in accommodating cutting-edge technologies. Numerous compelling factors contribute to the favoritism of Rogers 4835 over various alternative laminates.

Distinguished for its exceptional performance in high-frequency domains, the Rogers 4835 PCB serves as an exemplary solution for applications such as wireless communications and radar systems. Its capacity to sustain lower signal loss in high-frequency environments sets it apart from traditional laminates, ensuring the steadfastness and dependability of data transmission.

In the realm of electronic design, signal integrity assumes critical significance for high-speed, high-frequency applications. The Rogers 4835 PCB excels in this aspect, effectively governing signal transmission speed and upholding signal stability. This renders it particularly well-suited for managing high-speed data transmission, as seen in high-performance computing and communication equipment.

In response to the relentless evolution of science and technology, the demand for advanced capabilities in electronic equipment continues to surge. The Rogers 4835 PCB distinguishes itself with remarkable technical adaptability, catering to various advanced technology applications such as 5G communications and radio frequency antenna design. Its materials and manufacturing processes align seamlessly with evolving technical requisites, positioning it as a sustainable choice for the future.

Comparative analysis against traditional FR-4 laminates unequivocally underscores the advantages of Rogers 4835 in high-frequency applications. In the context of a high-frequency radar system, the utilization of Rogers 4835 PCB yields lower transmission loss and a heightened signal-to-noise ratio, thereby enhancing the overall system performance. This outstanding capability extends beyond the realm of communications, finding validation in diverse fields including medical equipment and satellite communications.

Overall, choosing Rogers 4835 PCB is equivalent to giving the project the superior performance and stability required for high-frequency applications. Its unique combination of signal integrity, high frequency performance and advanced technology adaptability ensures optimal results in increasingly complex electronic designs.

How to make Rogers 4835 PCB?

The production process of Rogers 4835 printed circuit boards (PCBs) is a crucial aspect of electronic engineering, exerting a direct impact on the ultimate performance and dependability of the end product. This article will delve into the manufacturing procedures involved in creating Rogers 4835 laminate, placing a special emphasis on the meticulous selection of materials and the utilization of specific production techniques.

Rogers 4835 laminate is preferred because it exhibits unique properties in specific applications. This is particularly evident in the choice of materials. Rogers 4835’s material has excellent electrical properties, making it stand out in high-frequency designs. This includes low losses, excellent dielectric constant and stable mechanical properties, making it ideal for high-performance circuit boards.

In high-frequency design, material selection is crucial. Rogers 4835 takes into account factors such as the propagation speed of electromagnetic waves and signal stability, allowing it to meet the high-frequency transmission requirements of advanced electronic equipment. Therefore, material selection is the first step in manufacturing a high-quality Rogers 4835 PCB.

Manufacturing Rogers 4835 PCBs relies heavily on cutting-edge production technologies to uphold superior board quality through precision manufacturing. Innovative processes play a pivotal role in meeting design specifications, and several advanced techniques are employed in the production of Rogers 4835.

Achieving precision begins with high-precision lamination technology, where meticulous attention is given to ensuring optimal interlayer connections and electrical performance. Precision cutting and drilling processes further contribute to the refinement of the PCB, all conducted under elevated temperatures and pressures to enhance overall quality.

The production of Rogers 4835 involves the integration of state-of-the-art technology. Advanced automation systems streamline manufacturing, while laser processing technology adds a layer of precision. To maintain consistency and stability, sophisticated inspection equipment is utilized. This amalgamation of cutting-edge technologies not only boosts manufacturing efficiency but also guarantees a standardized and stable product output.

By selecting unique materials and adopting advanced production techniques, electronic engineers can ensure that the circuit boards they obtain meet high-performance and high-reliability requirements, driving continuous innovation in electronic devices.

What are the application scenarios of Rogers 4835 PCB?

Rogers 4835 PCB is widely recognized as a premier selection in the realm of high-frequency laminates, earning praise for its outstanding performance and versatility across various industries. This in-depth overview will explore the extensive applications of Rogers 4835 PCB in telecommunications, aerospace, and satellite systems, showcasing its remarkable adaptability and reliability through real-world examples.

Within the dynamic landscape of the telecommunications industry, Rogers 4835 PCB emerges as an optimal solution for high-frequency applications. Whether integrated into base station equipment, communication antennas, or radio frequency front-end modules, its outstanding signal integrity and minimal loss characteristics ensure the seamless operation of communication networks.

Rogers 4835 PCB plays a crucial role in the aerospace sector, where there are strict requirements for reliability and performance. This specialized printed circuit board is essential for high-frequency electronic equipment employed in aircraft navigation systems, communication devices, and radar systems. Its use is integral to ensuring the effective operation of aerospace systems, meeting the demanding standards of the industry.

The Rogers 4835 PCB’s multi-field applications underscore its irreplaceable position. Through continual innovation, it consistently delivers outstanding performance in high-frequency applications, contributing significantly to the advancement of modern electronic design.

Real-world examples underscore the reliability and versatility of the Rogers 4835 PCB, solidifying its status as a preferred high-frequency laminate within the industry.

Where to find Rogers 4835 PCB?

In the contemporary landscape of fiercely competitive electronic design, the selection of a dependable and high-quality Rogers 4835 PCB supplier stands as a pivotal determinant for the success of your project. This guide aims to assist you in identifying the most fitting supplier from the multitude of options available. The initial and crucial stride involves the careful choice of a reputable manufacturer for Rogers 4835 PCBs, laying the foundation for assured quality and reliability in your project.

Consideration of supplier reliability is critical to project progress. A stable and orderly supply chain can ensure you receive a stable supply of Rogers 4835 PCB and avoid delays and production interruptions.

When selecting a provider for Rogers 4835 PCBs, it is crucial to prioritize those that provide exceptional technical support and customization capabilities. Given the diverse requirements of projects, a supplier with the adaptability to meet specific needs becomes a valuable partner.

We are pleased to declare with confidence that our company stands as a highly esteemed supplier within the Rogers 4835 PCB domain. Beyond holding a reputable manufacturer status, we boast robust associations with multiple top-tier dealers, guaranteeing the delivery of superior products and services to our clients.

Our Rogers 4835 PCB series utilizes advanced manufacturing techniques through carefully selected high frequency materials to ensure superior performance and reliability in a variety of high frequency applications. We are committed to providing customers with a full range of technical support to meet the unique needs of different projects.

Selecting a supplier for Rogers 4835 PCBs? Choose us for top-notch quality and reliability. Count on us to deliver the ideal solution for your project and establish a lasting partnership in high-frequency electronic design. We eagerly anticipate the opportunity to meet your needs and become your trusted, long-term collaborator.

How is the quote for Rogers 4835 PCB determined?

When examining the quotation of Rogers 4835 PCB, we inevitably involve a series of factors that affect the price. Understanding these cost considerations is critical to making informed decisions. The formation of a Rogers 4835 PCB quote and the key factors related to specification, complexity and production quantities are discussed in detail below.

The specifications of Rogers 4835 PCB are one of the first factors that determine its quotation. The thickness, size, number of layers and special requirements of the board will directly affect the production cost. Generally speaking, customized specifications may result in higher manufacturing costs, thus affecting the final quote.

The design complexity of the Rogers 4835 PCB is another key factor that determines the price. High-density, multi-level layouts and special technical requirements will increase the difficulty of the manufacturing process, thereby increasing costs. Increased complexity may require more advanced manufacturing techniques and tighter quality controls, which in turn will have a direct impact on quotes.

Production quantity is one of the important factors in determining Rogers 4835 PCB quotation. Typically, high-volume production may enjoy economies of scale that reduce manufacturing costs per unit. On the contrary, small batch production may require higher fixed cost allocation, so its price may be relatively high.

The materials used and special requirements of Rogers 4835 PCB will also directly affect the quotation. High frequency requirements, special dielectric constants, or special metal laminations can lead to increased raw material costs. Customized special requirements often require additional engineering and production adjustments, further impacting the overall quote.

Compliance with specific industry standards and certifications may have an impact on the quote for Rogers 4835 PCB. Ensuring that PCBs meet industry standards and quality certifications may require additional quality inspection and testing steps, thereby increasing manufacturing costs.

To sum up, the quotation of Rogers 4835 PCB is a complex calculation and is affected by many factors. Understanding specifications, complexity, production quantities, and other special requirements is critical to making informed decisions. When selecting a Rogers 4835 PCB, manufacturers and designers need to weigh a variety of factors to ensure the most economical solution while meeting quality and performance needs. By gaining an in-depth understanding of how a quote is formed, readers can better understand the true value of Rogers 4835 PCB and make informed and precise decisions for the success of their project.

Rogers 4835 PCB FAQ

What makes Rogers 4835 PCBs unique in the world of PCB engineering?

Rogers 4835 PCBs stand out due to their exceptional high-frequency performance, offering superior electrical characteristics and thermal stability. Their unique material properties make them an ideal choice for advanced electronic designs.

Are there different types of Rogers 4835 substrates available, and how do they cater to specific applications?

Yes, Rogers 4835 substrates come in various types, including standard laminates and high-frequency variants. Each type is designed to meet specific requirements, providing versatility for diverse electronic applications.

What advantages do Rogers 4835 PCBs offer over traditional substrates?

Rogers 4835 PCBs provide unparalleled benefits, such as low signal loss, excellent dielectric constant stability, and enhanced thermal performance. These advantages make them superior choices for high-frequency applications compared to traditional substrates.

How are Rogers 4835 PCBs manufactured, and what key considerations should be taken into account during the process?

The manufacturing of Rogers 4835 PCBs involves advanced processes and precise material selection. Considerations for high-frequency designs, unique material properties, and cutting-edge technologies contribute to the production of high-quality boards.

Are there any design considerations or compatibility issues when using Rogers 4835 PCBs?

Design considerations for high-frequency applications and compatibility assessments are crucial when using Rogers 4835 PCBs. Manufacturers often provide guidelines and support to ensure optimal performance in diverse electronic designs.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier