What are RT/duroid 5880 Substrates?

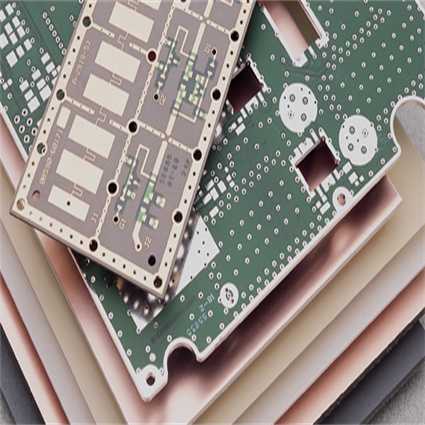

RT/duroid 5880 PCB manufacturer. Aeronautical and military electronic materials. RT/duroid 5880 laminates has a low dielectric constant (Dk) and low dielectric loss, making them well suited for high frequency/broadband applications. Helping to maintain the Dk uniformity are the randomly oriented microfibers reinforcing the PTFE composites.

Features

- Dk or 2.20 +/- .02

- Dissipation factor of .0009 at 10GHz

- Low moisture absorption

- Isotropic

Benefits

- Uniform electrical properties over wide frequency range

- Easily cut, shared and machined to shape

- Resistant to solvents and reagents used in etching or plating edges and holes

- Ideal for high moisture environments

- Well-established material

- Lowest electrical loss for reinforced PTFE material

RTduroid 5880 Substrates, as an innovative technology in the field of PCB engineering, plays a key role in connecting semiconductor chips and the entire PCB framework. Before we dive into the unique properties of RTduroid 5880, let’s consider how this material is changing the game for electronic connections.

RTduroid 5880 substrates play a crucial role in PCB design, serving as both a material and a connector that intimately links the semiconductor chip to the entire circuit board system. Distinguished by its unique features, this technology not only establishes a reliable electrical connection but also optimizes signal transmission efficiency, thereby enhancing the overall performance of electronic devices.

The groundbreaking status of this innovative technology in electronic engineering stems from its exceptional electrical performance. RTduroid 5880 substrates exhibit outstanding dielectric constant and low loss tangent values, particularly excelling in high-frequency applications. As a result, they emerge as the preferred choice for designing high-performance RF and microwave circuits.

In modern electronic devices, thermal effects have always been a design challenge that cannot be ignored. RTduroid 5880 Substrates effectively alleviates potential thermal problems through its excellent heat dissipation performance, ensuring that the device can still operate stably in high temperature environments.

The introduction of this material provides PCB engineers with greater design flexibility. The diversity of RTduroid 5880 Substrates makes it suitable for a variety of design needs, from high-frequency circuits to complex multi-layer board designs, you can find corresponding solutions.

Overall, the innovation of RTduroid 5880 Substrates is that it is not just a basic material, but also a link connecting various components of modern electronic devices. By understanding its unique properties, we can better understand how it is leading the way in electronic connectivity. In the future, with the continuous development of technology, RTduroid 5880 Substrates will continue to lead the wave of PCB innovation and promote electronic engineering to new heights.

What types of RTduroid 5880 Substrates are there?

In the field of modern PCB engineering, RTduroid 5880 Substrates has become a leading force in electronic design and manufacturing with its excellent performance and diverse types. From high-frequency variants to designs designed for specific applications, the diverse types of RTduroid 5880 Substrates meet the various needs of advanced electronic designs, providing engineers with flexible and customizable solutions.

High Frequency Variant: The high frequency variant of RTduroid 5880 Substrates exhibits excellent performance in high frequency applications. These substrates ensure superior signal transmission and fidelity in frequency-demanding environments through carefully tuned dielectric constants and loss factors.

Dedicated application design: The design diversity of RTduroid 5880 Substrates is not limited to common application scenarios. A variety of specially designed types, such as those used in aerospace, medical devices and communication systems, allow these substrates to precisely meet the unique needs of different industries.

Multi-layer structure: For complex circuits and high-density interconnection requirements, RTduroid 5880 Substrates provides multi-layer structure types. This allows engineers to achieve more functionality in a limited space while maintaining superior performance.

Thermal management optimization: For applications that have strict requirements on thermal management, RTduroid 5880 Substrates provides specially optimized types. These substrates effectively disperse and reduce the heat generated in electronic devices through unique thermally conductive materials and designs.

Highly Customizable: The flexibility of RTduroid 5880 Substrates allows them to be highly customized to meet the needs of specific projects. Engineers can choose different layer thicknesses, dielectric constants and other parameters to achieve the best balance of performance and size.

High temperature resistant type: For applications in high temperature environments, RTduroid 5880 Substrates provides high temperature resistant types to ensure reliable operation under extreme conditions.

The versatility of RTduroid 5880 Substrates makes them well-suited for a range of electronic design challenges. Various substrate types not only address diverse requirements but also empower engineers to unleash their creativity fully, enabling the design of more advanced and high-performance electronic devices.

What are the advantages of RTduroid 5880 Substrates?

In the field of modern PCB engineering, RTduroid 5880 Substrates, as a huge innovation in electronic design and manufacturing, is leading the change in the industry with its excellent performance and unique advantages. Here’s a closer look at how RTduroid 5880 Substrates’ unrivaled capabilities shape the overall performance of electronic devices in terms of electrical performance, thermal management, and signal integrity.

RTduroid 5880 Substrates stand out in terms of electrical performance. Its material properties and manufacturing process enable it to provide excellent electrical conductivity properties, ensuring efficient transmission of electronic signals. This advantage provides more stable and reliable electrical performance for high-frequency applications, opening up new possibilities for the design of advanced electronic devices.

RTduroid 5880 Substrates demonstrate strong capabilities in thermal management. Its excellent thermal conductivity properties allow this substrate to efficiently disperse and transfer heat, ensuring that electronic components always maintain a suitable temperature during operation. This unique thermal management advantage not only increases device reliability but also helps extend the life of electronic components.

RTduroid 5880 Substrates are engineered to uphold and enhance signal integrity, effectively minimizing distortion and noise during signal transmission. This substrate is specifically crafted to facilitate high-quality, high-fidelity signal transfer, a crucial aspect for applications demanding exceptionally pristine signal quality, such as communication and radar systems. The outstanding signal integrity provided by RTduroid 5880 Substrates ensures stable operation across diverse environments.

The combined effect of these advantages ultimately results in improved overall electronic device performance. RTduroid 5880 Substrates enable devices to run better in every aspect by delivering reliable, efficient electrical performance, superior thermal management and signal integrity. This not only meets the high performance and reliability requirements of modern electronic equipment, but also provides a strong foundation for future innovation.

Overall, the advantages of RTduroid 5880 Substrates are not just outstanding in a single aspect, but provide PCB engineers with a powerful and comprehensive tool through outstanding performance in electrical performance, thermal management and signal integrity. Promoting the advancement of electronic design and manufacturing.

Why choose RTduroid 5880?

In today’s evolving world of PCB engineering, it is critical to select a substrate suitable for high-frequency applications that emphasizes signal integrity and reliability. RTduroid 5880 Substrates, as an advanced substrate material, successfully breaks through the limitations of traditional materials and provides designers with new possibilities. Let’s dive into the comparison and see in which scenarios the RTduroid 5880 outperforms other baseboard options.

Excellence in high frequency applications

RTduroid 5880 stands out in high-frequency applications, boasting low dielectric constant and loss factor values that render it exceptionally well-suited for wireless communications, radar systems, and various high-frequency electronic devices. In comparison to conventional substrates, RTduroid 5880 delivers reduced signal attenuation and enhanced transmission efficiency, ensuring stellar system performance within high-frequency environments.

Signal Integrity Advantages

In electronic design, signal integrity is critical. RTduroid 5880 Substrates reduce the risk of signal distortion through its superior dielectric properties and interconnect design. For high-speed digital signals or microstrip line applications, RTduroid 5880’s low dispersion and low cross-coupling ensure the signal maintains its original quality, making it perform excellently in complex circuits.

Improved reliability

Compared with traditional substrates, RTduroid 5880 is more stable in temperature changes and humidity environments. Its fiberglass-reinforced polyimide material provides excellent mechanical strength and environmental resistance, allowing RTduroid 5880 to remain reliable in a variety of applications, especially under extreme operating conditions.

Through in-depth comparison with traditional materials, we can clearly see the excellence of RTduroid 5880 Substrates in high-frequency applications, signal integrity and reliability. In today’s era of pursuing more advanced and reliable electronic systems, choosing RTduroid 5880 becomes a powerful assistant in engineering design and promotes the continuous advancement of electronic engineering.

How are RTduroid 5880 Substrates made?

The manufacturing process of RTduroid 5880 Substrates involves complex and precise steps, with production from motherboard to substrate playing a key role. Here’s a closer look at this manufacturing process, exploring the key technologies and materials used to ensure these substrates meet exceptional quality standards.

Motherboard manufacturing

In the motherboard manufacturing process, accuracy is crucial. An accurate subtraction and addition process ensures that the shape, size and laminate structure of the motherboard meet design specifications. This requires advanced manufacturing equipment and technology to ensure that each step can be carried out accurately.

Integrating RTduroid 5880 is a key step to improve performance. By seamlessly integrating RTduroid 5880 into the motherboard, it not only improves electrical performance but also optimizes the efficiency of the entire system. This integration requires a deep understanding of materials and manufacturing processes to ensure RTduroid 5880 can fully realize its advantages.

Substrate manufacturing

In the realm of substrate manufacturing, the creation of high-density interconnects using RTduroid 5880 poses a significant technical challenge. These interconnects are tailored to meet the evolving demands of contemporary electronic devices, necessitating smaller form factors and heightened performance. The utilization of RTduroid 5880 enables manufacturers to realize more compact and higher-density interconnect structures, thereby enhancing overall circuit performance.

The selection of advanced materials is pivotal in guaranteeing the reliability of the substrate during this intricate process. RTduroid 5880, being inherently high-performance, provides a robust foundation with its distinctive electrical properties and exceptional temperature resistance. When combined with other cutting-edge materials, manufacturers can ensure the stable and reliable operation of substrates across diverse environmental conditions.

In essence, the manufacturing of RTduroid 5880 substrates transcends a mere processing endeavor; it embodies a scientific pursuit. A profound comprehension of the crucial steps in motherboard and substrate manufacturing, coupled with the integration of advanced technologies and materials, is imperative. This understanding illuminates the pivotal role played by these substrates in the realm of modern electronic devices, underscoring their significance in achieving superior performance.

RT/duroid 5880 PCB Manufacturer

What are the application scenarios of RTduroid 5880 Substrates?

RTduroid 5880 substrates serve as a pivotal element in electronic design, playing a disruptive role that fuels innovation across various industries. This article will explore the diverse applications of RTduroid 5880 substrates in numerous sectors, ranging from aerospace to telecommunications. It will illustrate how these substrates empower engineers to make significant advancements in electronic design, fostering breakthrough achievements in their respective fields.

Aerospace field

The application of RTduroid 5880 Substrates in the aerospace field cannot be ignored. In this field where lightweight and high performance are extremely important, the high frequency characteristics and excellent signal integrity of RTduroid 5880 make it an ideal choice. From avionics to satellite communication systems, RTduroid 5880 Substrates has demonstrated strong application potential in the aerospace field with its reliability and advanced nature.

Communication field

In the rapidly developing communications field, RTduroid 5880 Substrates has demonstrated its unique value in high-frequency applications. From tiny communications devices to large base stations, these substrates provide communications engineers with a reliable platform that supports efficient signal transmission and processing. Its excellent performance makes it ideal for meeting the needs of rapid communication development.

Medical electronics field

Medical electronic equipment has very high requirements for stability and accuracy, and RTduroid 5880 Substrates are ideal for meeting these needs. From laser medical equipment to high-resolution imaging systems, RTduroid 5880’s wide application in the field of medical electronics enables the development and promotion of advanced medical technology.

Automotive electronics field

With the rapid intelligence of automotive electronics, RTduroid 5880 Substrates play a key role in the field of automotive electronics. From advanced driver assistance systems to entertainment devices, these substrates provide reliable electrical connections and superior performance, enabling innovative solutions for automakers.

Industrial automation field

In industrial automation, the high temperature stability and reliability of RTduroid 5880 Substrates make it the first choice for control systems and sensors. Its advanced manufacturing processes and materials ensure stable operation in extreme industrial environments and provide strong support for industrial automation.

RTduroid 5880 Substrates serve as more than just a material base; they stand as a formidable ally in driving technological advancements across various industries. Their extensive utilization in aerospace, communications, medical, automotive, and industrial automation underscores not only their exceptional performance but also presents engineers with limitless potential. This, in turn, propels ongoing progress in electronic design. As technology marches forward, RTduroid 5880 Substrates are poised to spearhead the innovation surge in electronic design.

Where to find RTduroid 5880 Substrates?

In the pursuit of excellence in electronic design and manufacturing, the meticulous selection of high-quality RTduroid 5880 Substrates stands as a paramount priority. As a distinguished manufacturer and distributor, our company is unwaveringly dedicated to providing superior RTduroid 5880 Substrates meticulously crafted to meet the precise requirements of your projects.

When in search of RTduroid 5880 Substrates, the consideration of reputation becomes pivotal. We strongly advocate for opting for manufacturers and distributors with an illustrious industry standing to ensure the steadfast reliability of the products you acquire. Our company has earned widespread acclaim for consistently delivering products of exceptional quality and upholding a steadfast commitment to professional service, positioning us as your reliable and esteemed partner.

Acknowledging the distinctive nature of each project, we extend bespoke RTduroid 5880 Substrates solutions. Through collaboration with us, you gain access to expert consultation and tailored customization options, ensuring the seamless realization of your project. Our adept team works closely with you to devise the optimal solution tailored precisely to your unique needs and specifications.

Selecting us as your RTduroid 5880 Substrates supplier comes with several advantages for our customers:

Excellent Quality Control:Adhering to stringent quality control processes, we ensure that each RTduroid 5880 Substrate complies with the highest industry standards.

Customized Services: Our team engages with you to comprehend your project requirements, delivering a personalized RTduroid 5880 Substrates solution that caters to your unique needs.

Punctual Delivery Assurance:Dedicated to delivering on time, we are committed to ensuring the timely arrival of your orders. This commitment is aimed at fostering seamless project progress and minimizing any avoidable delays.

Expert Technical Assistance:Backed by a seasoned technical team, we provide professional support and solutions whenever required. Our goal is to empower you to maximize the benefits of RTduroid 5880 Substrates in your applications.

When looking for RTduroid 5880 Substrates suppliers, choose manufacturers and distributors with excellent reputations and reliable quality. With its excellent service and professional team, our company will provide you with the best RTduroid 5880 Substrates solution to help you succeed in the field of electronic design and manufacturing. Choose our company, choose reliability and excellent quality.

What is the quote for RTduroid 5880 Substrates?

In the realm of electronics design and manufacturing, the careful selection of substrate materials holds paramount importance. RTduroid 5880 substrates have garnered significant attention owing to their exceptional performance. However, a thorough comprehension of the cost structure is imperative for making well-informed decisions. This article aims to delve into the quotes associated with RTduroid 5880 substrates, offering readers valuable insights into cost considerations. It will explore how to interpret pricing, considering diverse specifications, complexity levels, and production volumes.

The specifications of RTduroid 5880 Substrates are one of the first factors that determine its price quote. High-frequency applications often require more stringent specifications, which may involve special requirements for materials and more precise manufacturing processes. Hence, the pricing will increase accordingly as the specifications increase. We recommend that readers carefully consider the specific specifications of their projects when selecting materials to ensure performance standards are met while cost is controlled.

The complexity of RTduroid 5880 Substrates also has a significant impact on pricing. Some projects may require multi-layer structures, high-density interconnects or special inter-layer structures. These complexity elements will directly affect the difficulty and cost of the manufacturing process. Therefore, when developing a budget, customers should have a clear understanding of the design requirements for their project and work with the manufacturer to research the optimal configuration of complexity.

Production volume is the third key factor that affects RTduroid 5880 Substrates pricing. Generally speaking, mass production tends to lead to better economics because manufacturers can use resources more efficiently. Conversely, low-volume production may involve higher unit costs. Understanding the expected production volume of the project will help customers develop the most economical and reasonable cost plan.

Understanding the cost structure of RTduroid 5880 Substrates is key to ensuring you can confidently navigate the pricing landscape. First, the customer should fully communicate with the manufacturer to discuss the project’s technical and design requirements in detail. Secondly, it is recommended that the expected range of specifications, complexity and production volumes be clear early on in the project so that the manufacturer can provide an accurate quote. Finally, project requirements are regularly reviewed and updated to accommodate any changes, ensuring maximum cost optimization throughout the production process.

Overall, quoting RTduroid 5880 Substrates is a complex and comprehensive process that requires the consideration of multiple factors. By gaining a deeper understanding of the impact of specification, complexity, and production volumes on costs, readers will be better equipped to budget for costs and ensure the quality and economic success of their projects.

Common problem

What distinguishes RTduroid 5880 Substrates from other PCB materials?

RTduroid 5880 Substrates set themselves apart through their exceptional electrical performance, advanced thermal management, and suitability for high-frequency applications. These unique characteristics make them a preferred choice in modern electronic designs.

Are RTduroid 5880 Substrates suitable for high-density interconnects?

Absolutely. RTduroid 5880 Substrates are designed to excel in creating high-density interconnects, providing engineers with the flexibility and precision required for intricate electronic layouts.

Can RTduroid 5880 Substrates be customized for specific project requirements?

Yes, RTduroid 5880 Substrates offer customization options to meet specific project requirements. Discuss your needs with manufacturers to explore tailored solutions for your unique electronic designs.

What distinguishes RTduroid 5880 Substrates from traditional PCB materials?

RTduroid 5880 Substrates offer superior high-frequency performance, enhanced thermal management, and improved signal integrity compared to traditional materials. The unique composition and advanced technology make them stand out in the field of electronic design.

Can RTduroid 5880 Substrates be customized for specific project requirements?

Yes, RTduroid 5880 Substrates offer customization options to meet specific project needs. Engineers can tailor the substrate specifications, including thickness and dielectric constant, ensuring compatibility with diverse applications and design considerations.

How do the manufacturing processes of RTduroid 5880 Substrates differ from traditional PCBs?

The manufacturing of RTduroid 5880 Substrates involves advanced processes, including precise subtractive and additive techniques. The integration of RTduroid 5880 in both motherboard and substrate production ensures optimized performance and reliability, setting it apart from conventional PCB manufacturing.

Are RTduroid 5880 Substrates cost-effective for large-scale production?

RTduroid 5880 Substrates can offer cost-effective solutions for large-scale production, especially when considering their enhanced performance and reliability. Discussing project specifications with suppliers and exploring bulk purchase options can lead to optimized cost structures.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier