BT Laminate substrate Manufacturer. High speed and high frequency material BT packaging substrate Manufacturer. Advanced HDI PCB and BGA packaging substrate production.

In today’s high-tech world, printed circuit boards (PCBs) are a key component of many electronic products. In the selection of PCB materials, BT laminated substrates are highly favored due to their excellent performance and reliability. BT laminated substrate, namely Bismaleimide Triazine (triazine diimide) laminated substrate, is a high-performance material commonly used in the manufacture of high-frequency circuits and microwave circuits. This article will delve into the manufacturing process, application fields and manufacturers behind BT laminated substrates, and present you with a comprehensive guide to BT laminated substrates.

What is BT Laminate substrate?

BT laminated substrate, that is, Bismaleimide Triazine (triazine diimide) laminated substrate, is a highly respected high-performance material in today’s electronics industry. It is usually widely used in manufacturing high-frequency circuits and microwave circuits, such as radio frequency (RF), microstrip lines, and antennas. BT laminated substrate has become an indispensable component of many electronic products due to its unique structure and excellent performance.

The composition of BT laminated substrate mainly includes two key components: BT resin and glass fiber layer. BT resin is a special thermosetting resin with excellent heat resistance and chemical stability, and can maintain stable electrical properties in high temperature environments. The glass fiber layer gives the substrate good mechanical strength and dimensional stability, allowing it to withstand the challenges of complex processing and use environments.

Due to its special material composition and structural design, BT laminated substrate has many excellent electrical properties. It has the characteristics of low loss, low dielectric constant, low dispersion, etc., which can effectively reduce energy loss and signal distortion during signal transmission, thus ensuring the stability and reliability of the circuit. In addition, BT laminated substrates also have good high temperature resistance and can maintain good performance in extreme working environments, such as aerospace, automotive electronics and other fields.

BT Laminate BGA substrate Manufacturer

In general, BT laminated substrate has become an indispensable and important component of modern electronic products due to its unique material properties and excellent performance. It is not only widely used in high-frequency circuits and microwave circuits, but also shows great potential in communications, aerospace, medical and other fields. With the continuous development of the electronics industry, it is believed that BT laminated substrates will continue to play an important role and provide strong support for the performance improvement and innovation of various electronic products.

BT Laminate substrate design Reference Guide.

Choosing the right BT laminate substrate manufacturer is critical to ensuring product quality and project success. A first-class manufacturer is not just a product supplier, but also your partner, able to work with you to meet challenges and achieve a win-win situation.

First of all, a first-class BT laminated substrate manufacturer should have advanced production equipment and technology. This includes high-precision production lines, advanced processing equipment, and strict quality control systems. Only with these equipment and technologies can manufacturers produce BT laminated substrates that meet high standards and ensure their stable performance and reliability.

Secondly, the manufacturer should be able to provide high-quality products. This means they should use high-quality raw materials and conduct strict quality control throughout the production process. Only in this way can we ensure that the BT laminated substrates produced have excellent performance indicators and meet customer needs.

Additionally, the manufacturer should be able to guarantee on-time delivery. In the modern business environment, time is money. A first-class manufacturer should be able to reasonably arrange production plans according to customer needs and ensure on-time delivery of products. This can help customers avoid losses caused by delayed delivery and ensure smooth project progress.

In addition, manufacturers should also have good technical support and after-sales service. Customers may encounter various problems during the use of BT laminated substrates, and manufacturers should be able to provide technical support in a timely manner and solve customer problems. At the same time, manufacturers should also provide timely after-sales service to ensure customer satisfaction and loyalty.

To sum up, choosing the right BT laminate substrate manufacturer is crucial. A first-class manufacturer is not just a product supplier, but also your partner, able to provide high-quality products, on-time delivery, good technical support and after-sales service. Hopefully these tips will help you find the manufacturer that best suits your needs and have a successful project together.

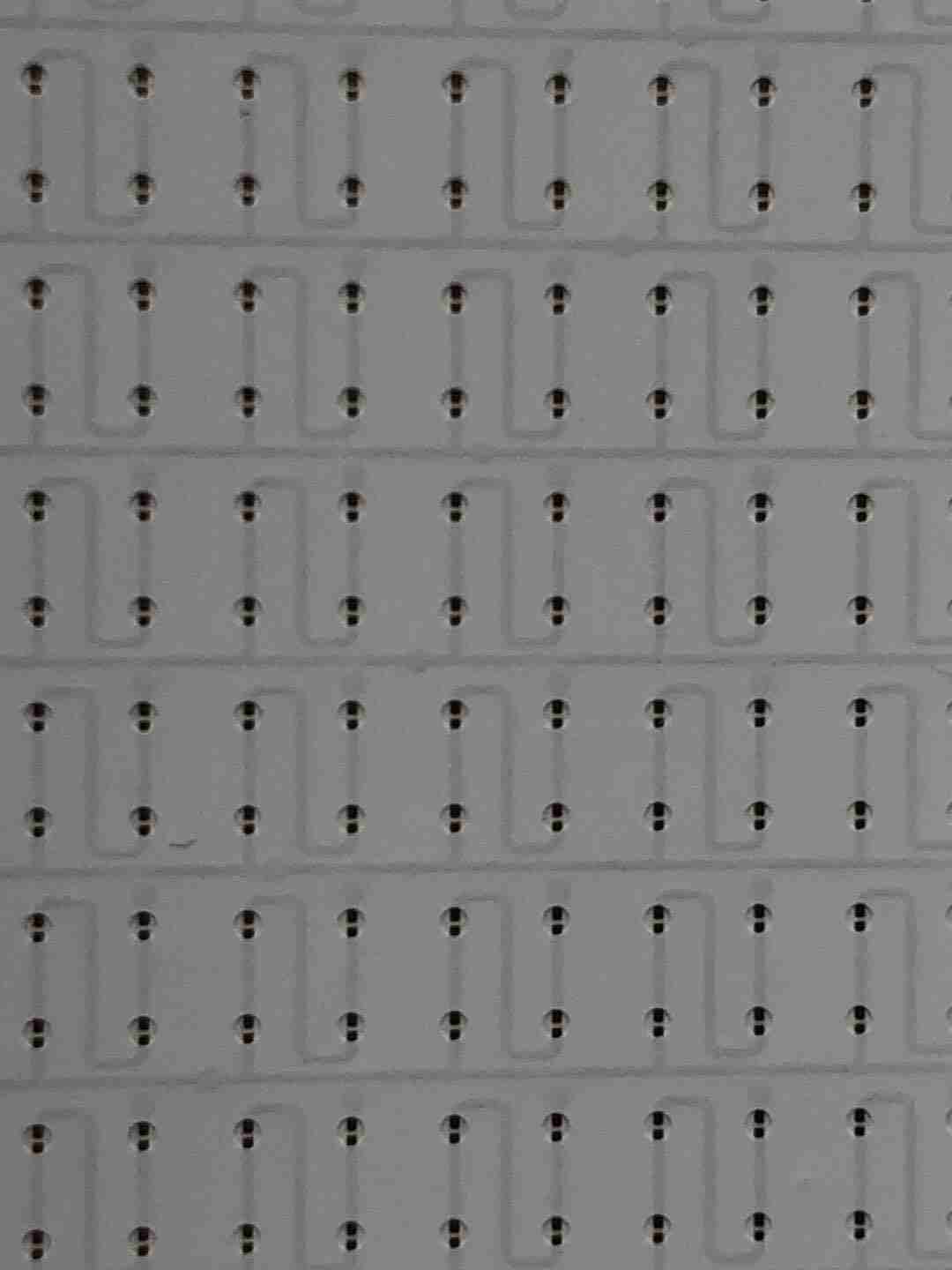

White BT LED PCBs

What material is used in BT Laminate substrate?

BT laminated substrate (Bismaleimide Triazine) is composed of a variety of materials, each of which plays an important role in the performance and functionality of the substrate. During the manufacturing process of BT laminate substrates, careful selection and combination of these materials is crucial to ensure the quality and reliability of the final product.

BT resin: BT resin is one of the core materials of BT laminate substrate. It is a high-performance resin with excellent thermal properties and chemical stability. The characteristics of BT resin enable BT laminated substrates to maintain stable performance under high temperatures, high humidity and harsh environments, making them suitable for various application scenarios.

Fiberglass layer: The fiberglass layer is one of the reinforcing materials of BT laminated substrate. It usually comes in the form of elongated fiberglass cloth or yarn that is impregnated in BT resin. The glass fiber layer can increase the mechanical strength and rigidity of the substrate, giving the substrate good impact resistance and bending resistance.

Fillers: During the manufacturing process of BT laminated substrates, some fillers are often added to adjust the properties of the substrates. These fillers can be materials such as silica gel, aluminum oxide, and zinc oxide, which can affect the thermal conductivity, dielectric properties, and dimensional stability of the substrate.

Fire retardant: In order to improve the flame retardant performance of BT laminated substrate, some fire retardants are usually added, such as bromide, chloride, etc. These fire retardants can release gas when the substrate is burned by flames, forming a protective layer to prevent the spread of flames and protect the safety of circuit boards and equipment.

Filling materials: Sometimes some filling materials are added to the BT laminated substrate, such as ceramic beads, alumina powder, etc. These filler materials can adjust the dielectric constant, dielectric loss, and thermal conductivity of the substrate to meet the requirements of a specific application.

In summary, the performance and characteristics of BT laminate substrates depend on the selection and combination of multiple materials. Through careful design and manufacturing processes, BT laminated substrates are able to provide excellent electrical, thermal and mechanical properties and are suitable for the manufacturing and application of various high-end electronic products.

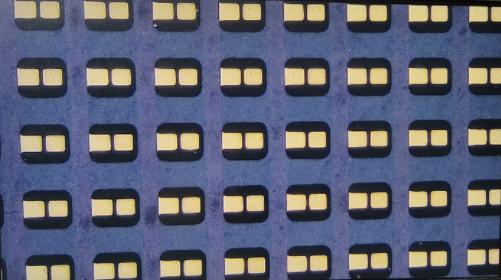

Black BT LED PCBs

What size are BT Laminate substrate?

As a highly customized electronic material, the size of BT laminated substrate can be adjusted and customized according to the specific needs of customers. From micro devices to large systems, BT laminated substrates can adapt to the requirements of various application scenarios.

In practical applications, the thickness of BT laminate substrates usually ranges from tens to hundreds of microns. This range of thicknesses provides flexibility so that the substrate can meet the needs of different circuit designs. For some high-density circuits, thinner BT laminate substrates can reduce the overall thickness of the circuit board, thereby saving space and improving circuit board performance. For some applications that require higher mechanical strength or thermal stability, thicker substrates may be selected.

In addition, the size of the BT laminated substrate can also be flexibly adjusted. The size ranges from a few millimeters to tens of centimeters to meet the size and shape requirements of different electronic devices. For some micro devices, such as smartphones, tablets, etc., very small size BT laminate substrates may be required to fit into compact spaces. For some industrial equipment or communication systems, a larger size substrate may be required to accommodate more electronic components and connectors.

In general, BT laminate substrates are available in flexible sizes and can be customized according to specific application needs. Manufacturers can usually produce BT laminate substrates that meet specific size and thickness requirements based on design documents or requirements provided by customers. This customized feature makes BT laminated substrates an ideal choice for many electronic products, able to meet the needs of different industries and application fields.

When selecting a BT laminated substrate, in addition to considering its electrical performance and material characteristics, you also need to consider whether its size and thickness meet the design requirements to ensure the performance and reliability of the final product. Therefore, it is very important to fully communicate with the manufacturer and clearly state the size and shape requirements of the product. Only in this way can we obtain a BT laminated substrate that meets expectations and provide a reliable foundation for the design and manufacturing of electronic products.

Through continuous innovation and technological progress, the size range and performance characteristics of BT laminated substrates will continue to be expanded and improved, bringing more possibilities and opportunities to the development of the electronics industry.

The Manufacturer Process of BT Laminate substrate.

When it comes to the manufacturing process of BT laminated substrates, we need to understand how these substrates are transformed from raw materials into final products. Below we will delve into the manufacturing process of BT laminate substrates to better understand the key steps involved.

The manufacturing of BT laminate substrates begins with the preparation of raw materials. The main materials include BT resin, fiberglass cloth, filler, etc. These raw materials need to undergo strict quality inspection and screening to ensure the performance and reliability of the final product.

During the manufacturing process, fiberglass cloth is soaked in pre-formulated BT resin. This step is to ensure that the fiber cloth can be fully soaked and combined with the resin to form a substrate with good mechanical strength and electrical properties.

Resin-impregnated fiberglass cloth will be stacked into multiple layers to create a substrate of the required thickness. These stacked layers are then laminated in a high-pressure environment to ensure a tight bond between the layers and eliminate possible air bubbles and defects.

After lamination is completed, the substrate will be sent to a hardening furnace for thermal curing. Under the high temperature and pressure environment, the resin will be completely cured, allowing the substrate to obtain the required mechanical properties and thermal stability.

The hardened substrate is precisely cut and machined to obtain the required size and shape. This step typically involves cutting, aperture drilling, milling and other processes to ensure that the substrate meets the customer’s requirements and design specifications.

Throughout the manufacturing process, advanced processes and equipment play a vital role. Precise control and monitoring systems can ensure the stability and consistency of product quality, improve production efficiency and reduce the rate of defective products. At the same time, strict control of the production environment is also one of the key factors to ensure the performance and reliability of BT laminated substrates.

In general, the manufacturing process of BT laminated substrate is a precise and complex process that requires a high degree of technology and experience. Through continuous innovation and improvement, BT laminated substrate manufacturers are able to provide higher quality products to meet the needs of different customers and application scenarios.

The Application area of BT Laminate substrate.

BT laminated substrate (Bismaleimide Triazine) has been widely used in many fields due to its excellent performance and reliability. The following will introduce the specific applications of BT laminated substrates in the fields of communications, automobiles, aerospace and medical.

In the field of communications, BT laminated substrates are widely used in the manufacture of high-frequency circuits and microwave circuits, such as communications equipment, antenna systems, and satellite communications equipment. Its excellent high-frequency characteristics and low-loss characteristics make it one of the preferred materials in the field of wireless communications. In the development of 5G communication technology, BT laminated substrate also plays an important role, supporting the realization of high-speed data transmission and low-latency communication.

Automotive electronic systems have extremely high requirements for high performance and reliability, so the application of BT laminated substrates in the automotive field is also increasing. It is used to manufacture electronic components such as engine control modules, in-car entertainment systems, and navigation systems. With the rapid development of electric vehicles and autonomous driving technology, the application of BT laminated substrates will become more widespread.

The aerospace field has extremely high requirements for material performance. BT laminated substrates have important applications in the aerospace field because of their excellent thermal stability and mechanical properties. It is used to manufacture key components such as aircraft radar systems, navigation systems, and communication equipment to ensure the stability and reliability of aerospace vehicles.

In medical device manufacturing, BT laminate substrates also play an important role. It is used to manufacture electronic components for high-performance medical equipment such as medical imaging equipment, vital sign monitoring equipment, and laser therapy equipment. Its stable performance and reliability ensure the accuracy and safety of medical equipment and play an important supporting role in the development of the medical industry.

In general, BT laminated substrates are widely used in communications, automobiles, aerospace and medical fields. Due to its excellent performance and reliability, it is widely used in the manufacture of high-frequency circuits, microwave circuits, antennas and other products, providing strong support and guarantee for the development of various industries.

What are the advantages of BT Laminate substrate?

In the electronics industry, BT laminated substrates are favored in many application fields due to their unique performance advantages. Compared with other materials, BT laminated substrate has many advantages. The following is a detailed introduction to some of them:

Excellent high-frequency characteristics: BT laminated substrate has excellent high-frequency characteristics and can maintain stable signal transmission at high frequencies. This makes it an ideal choice for manufacturing high-frequency circuits and microwave circuits, such as wireless communication equipment, radar systems, etc., and can meet the requirements of complex circuit design.

Excellent thermal stability: The BT resin of the BT laminate substrate has excellent thermal stability and can maintain stable performance in high temperature environments. This enables BT laminated substrates to perform well in high-temperature applications, such as automotive electronics, aerospace and other fields, and can maintain stable working conditions in harsh environments.

Good mechanical strength: BT laminated substrate has excellent mechanical strength and can withstand large mechanical stress without being prone to deformation or cracking. This makes it very reliable when manufacturing products that require mechanical stability, such as industrial control systems, medical equipment, etc., ensuring long-term stable working performance.

Dimensional stability: BT laminated substrate has good dimensional stability and can maintain its size without changing easily even under large changes in temperature or environmental humidity. This enables BT laminated substrates to perform well in applications that require precise dimensional control, such as precision instruments, optical equipment, etc., ensuring product performance stability.

In general, BT laminated substrates are widely used in the electronics industry due to their excellent high-frequency characteristics, thermal stability, mechanical strength and dimensional stability, and continue to promote technological development and innovation. Choosing BT laminated substrate as the material for circuit design will provide strong support for product performance and reliability.

FAQ

What are the applications of BT laminated substrates in the communications field?

In the field of communications, BT laminated substrates are often used to manufacture high-frequency antennas, microwave radio frequency modules, communication base stations and other equipment. Its excellent high-frequency characteristics and thermal stability make it one of the preferred materials for communication equipment manufacturers.

What is the difference between BT laminate substrate and FR4 substrate?

BT laminate substrates have lower dielectric constant and loss factor than traditional FR4 substrates, thus performing better in high frequency and microwave applications. In addition, BT laminated substrates have better thermal stability and dimensional stability and are suitable for applications in high temperature environments.

What is the price of BT laminated substrate?

The price of BT laminated substrates depends on many factors, including sheet thickness, size, number of layers, surface treatment, etc. Normally, due to its high performance and special manufacturing process, the price of BT laminated substrate is relatively high, but in some applications with higher performance requirements, its cost performance is still high.

How does the BT laminate substrate perform in high temperature environments?

BT laminate substrates have excellent thermal stability and can maintain good performance over a wide temperature range. They are typically capable of operating at temperatures up to over 150°C and can withstand transient high temperature shocks.

How difficult is it to process BT laminated substrates?

Due to the material characteristics and structural design of BT laminated substrates, its processing difficulty is relatively high. Especially in process steps such as drilling and line formation, specialized equipment and processes are required. Therefore, it is crucial to choose an experienced manufacturer to ensure the processing quality and stability of the product.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier