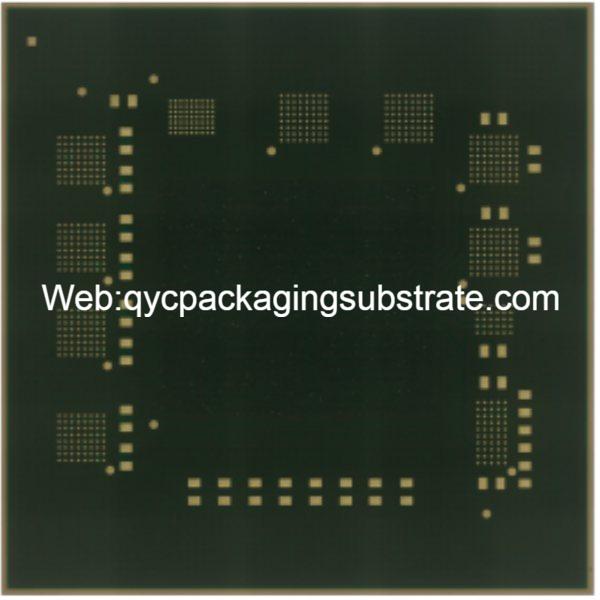

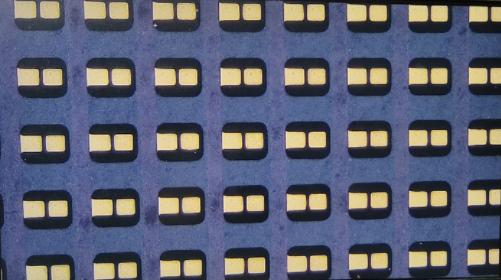

Bt laminate substrate manufacturing. BT resin has a wide range of materials, we can use the BT base to make the Mini LED PCBs. we also have used the BT base produce the BGA/IC package substrates from 2 layer to 20 layers.

BT laminated substrate, full name Bismaleimide Triazine, is a special laminate material whose matrix uses triazine resin and bismaleimide resin. This material is known for its excellent electrical properties, excellent high temperature resistance, and excellent mechanical strength.

In electronic manufacturing, BT laminate substrates play a vital role. First of all, it has excellent electrical performance, can effectively transmit signals and reduce signal attenuation, thereby ensuring the stable performance of electronic equipment. Secondly, BT laminated substrates can withstand working conditions in high-temperature environments and maintain the stability and reliability of the material, which is particularly important for some applications that require high-temperature operations. In addition, the BT laminated substrate also has good mechanical strength and can resist the influence of external environmental factors such as vibration and impact, ensuring the normal operation of electronic equipment under harsh conditions.

Bt laminate substrate manufacturing

Therefore, BT laminated substrates are widely used in electronic manufacturing, covering many fields such as communication equipment, consumer electronics, industrial control systems, and medical equipment. Its excellent performance and stability make it one of the preferred materials for many electronic products, providing reliable support for the development of the electronics industry.

What is the manufacturing process of BT laminated substrate?

The manufacturing process of BT laminate substrates begins with the preparation of raw materials. The main raw materials include triazine resin, bisimide resin and glass fiber cloth. The quality and purity of these raw materials are critical to the performance of the final product.

Next, the fiberglass cloth needs to be pretreated to enhance its surface roughness and improve the adhesion between the resin and fiber. This step ensures that the resin can fully penetrate into the fibers, resulting in a strong substrate.

The pretreated fiberglass cloth is then impregnated in a mixture of triazine resin and bisimide resin. This process ensures that the resin can fully penetrate into the fibers and solidify into a strong structure during subsequent pressing.

Impregnated fiber cloth is laminated together to create a multi-layer structure. The importance of this step is to determine the thickness and layering of the final product to meet the needs of different application scenarios.

The laminated materials are put into a press and pressed under high temperature and pressure. During this process, the resin is heated and solidified, forming a strong laminate. The parameters of the pressing process such as temperature, pressure and time need to be strictly controlled to ensure the quality and performance of the final product.

Finally, the pressed sheets are cut to the required size and shape. This step is typically performed using mechanical or laser cutting techniques to ensure precision and consistency.

Through the above steps, the production process from raw materials to final products is completed. BT laminated substrates are widely used in various electronic devices due to their excellent performance and stability, providing reliable basic materials for modern electronic manufacturing.

How to Design a Bt laminate substrate manufacturing?

Designing BT laminate substrate manufacturing typically involves several key steps and factors:

Material Selection: Firstly, suitable materials for BT laminate substrates need to be chosen. BT (Bismaleimide Triazine) is a high-performance resin often combined with glass fiber or other reinforcing materials to make laminates. Therefore, in the design process, appropriate resins and reinforcing materials must be selected, ensuring they meet the required performance and specification requirements.

Laminate Structure Design: Design an appropriate laminate structure based on the desired thickness and number of layers. Mechanical strength, thermal conductivity, electrical properties, and other requirements of the laminate need to be considered during the design process. Additionally, arranging the stacking sequence and thickness distribution of each layer appropriately is essential.

Printed Circuit Board (PCB) Design: Design the layout and circuit connections of the PCB according to specific circuit design requirements. During the design process, factors such as optimizing the circuit layout, signal integrity, and electrical performance need to be considered. Moreover, ensuring the PCB design conforms to the manufacturing process requirements of BT laminate substrates is crucial.

Printing and Hot Pressing: Print the designed PCB pattern onto the BT laminate substrate and conduct a hot pressing process to bond the various layers together. Controlling parameters such as pressure, temperature, and time during this process ensures the quality and stability of the laminate.

Post-Manufacturing Processes: Conduct necessary post-manufacturing processes such as surface treatment, trimming, drilling, etc., to meet the requirements of the final product.

Quality Control and Testing: Perform quality control and testing to ensure the manufactured BT laminate substrate meets design requirements and standards, possessing stable performance and reliable quality.

In summary, designing BT laminate substrate manufacturing involves several aspects such as material selection, laminate structure design, PCB design, printing and hot pressing, post-manufacturing processes, and quality control and testing. Through proper design and rigorous control of the manufacturing process, BT laminate substrate products with excellent performance and reliable quality can be produced.

BT laminate substrate

How to manufacturing a Bt laminate substrate manufacturing?

Manufacturing BT laminate substrates typically involves the following key steps:

Material Preparation: Prepare materials such as BT resin, glass fiber cloth, or other reinforcing materials. Ensure the quality of materials meets requirements and carry out necessary processing and preparation.

Raw Material Mixing: Mix BT resin with reinforcing materials like glass fiber cloth in certain proportions. Ensure thorough infiltration and coverage of resin onto the reinforcing materials through stirring or spraying.

Molding and Pressing: Place the mixed materials into molds and conduct molding and pressing. Adjust parameters such as temperature, pressure, and time as needed to achieve the desired thickness and performance of the laminate.

Drying and Curing: After molding, the laminate undergoes drying and curing to ensure complete resin curing and to provide stable performance.

Cutting and Trimming: Cut and trim the cured laminate to obtain the desired dimensions and shape of the BT laminate substrate.

Surface Treatment: Conduct surface treatment on the BT laminate substrate as required, such as polishing, cleaning, coating, etc., to improve surface quality and enhance specific functions.

Quality Inspection: Perform quality inspection on manufactured BT laminate substrates, checking parameters such as thickness, flatness, surface quality, etc., to ensure products meet specifications.

Packaging and Storage: Finally, package the qualified BT laminate substrates appropriately and store them properly to ensure products remain undamaged during transportation and use.

Through these manufacturing steps, BT laminate substrates with stable performance and high-quality can be produced, meeting the requirements of various electronic devices and applications.

How Much Does a Bt laminate substrate manufacturing Cost?

The manufacturing cost of BT laminate substrates is influenced by various factors, making it difficult to provide specific cost figures. Here are some key factors affecting the manufacturing cost of BT laminate substrates:

Raw Material Cost: Manufacturing BT laminate substrates requires materials such as BT resin, glass fiber cloth, or other reinforcing materials, and fluctuations in their prices directly impact manufacturing costs.

Production Processes: Different production processes and manufacturing technologies affect costs. For instance, employing automation equipment and advanced processes may increase costs but can also enhance production efficiency and product quality.

Production Scale: Generally, large-scale production can lower unit costs as fixed costs can be spread over more products. Conversely, small-scale production may lead to higher unit costs.

Labor Costs: Labor costs are a significant component of manufacturing costs. The wage level and the number of working hours directly affect manufacturing costs.

Equipment Investment and Maintenance Costs: Purchasing production equipment and facilities requires investment, and regular maintenance and upkeep costs also contribute to manufacturing costs.

In summary, the manufacturing cost of BT laminate substrates is influenced by various factors such as raw material costs, production processes, production scale, labor costs, and equipment investment and maintenance costs. To obtain an accurate cost estimate, detailed cost analysis and evaluation are necessary.

Who manufactures Bt laminate substrate manufacturing?

Want to get high-quality BT laminate substrates? Don’t worry, we’ve got several ways for you to get your hands on this critical electronics manufacturing material. As a supplier of our company, you can be assured of getting high-quality BT laminated substrates that meet your needs.

First, you can directly contact the professional BT laminate substrate supplier. These suppliers have extensive experience and technology and are able to offer BT laminate substrates in various specifications and models to meet your specific needs. They usually have advanced production equipment and strict quality control systems to ensure stable and reliable product quality.

Secondly, you can also look for BT laminate substrate suppliers on various online marketplaces. Online marketplaces such as Alibaba, Amazon, etc. offer a wide range of options and you can easily find multiple suppliers through the search function. When choosing a supplier, it is recommended to check their reviews and customer feedback to ensure you choose a reputable supplier with reliable quality.

Additionally, you can obtain BT laminate substrates through electronic component distributors. These distributors usually work with multiple suppliers and can provide you with a diverse selection of products and provide fast and convenient purchasing services. By working with a reputable electronic component distributor, you can more easily obtain the BT laminate substrates you need.

Finally, as a supplier of our company, you can directly contact our purchasing department to obtain high-quality BT laminated substrates that meet your needs. We will provide you with professional service and support to ensure you have a satisfactory purchasing experience and meet your production needs.

To sum up, through professional suppliers, online markets, electronic component distributors and cooperation with our company, you can easily obtain high-quality BT laminated substrates to provide stable and reliable material support for your electronic manufacturing projects.

What materials are Bt laminate substrate manufacturing made of?

BT laminate substrates are typically made of the following materials:

BT Resin: BT (Bismaleimide Triazine) resin is one of the primary components of BT laminate substrates. It possesses excellent high-temperature resistance, chemical stability, and mechanical strength, making it suitable for manufacturing high-performance electronic products.

Reinforcing Materials: Glass fiber cloth or other reinforcing materials are commonly used as the substrate for BT laminate substrates. These reinforcing materials enhance the substrate’s mechanical strength and durability while aiding in heat dispersion.

Filler Materials: Filler materials are used to improve the performance and processing characteristics of the substrate. The choice of filler material can affect the substrate’s insulation performance, thermal conductivity, etc.

Thermal Conductive Layer: To enhance the substrate’s thermal dissipation performance, a thermal conductive layer may sometimes be added to BT laminate substrates. Common thermal conductive materials include copper foil, among others.

Conductive Layer: For BT laminate substrates requiring circuitry layout on the surface, a conductive material such as copper foil is typically coated on the surface to facilitate circuit connections.

In summary, BT laminate substrates are manufactured using a variety of materials including BT resin, reinforcing materials, filler materials, thermal conductive layers, and conductive layers. These materials work together to ensure BT laminate substrates have excellent performance and stable quality, suitable for various electronic devices and applications.

What are 5 qualities of a good customer service?

Good customer service is essential for maintaining customer satisfaction and fostering strong customer relationships. Here are five qualities of excellent customer service:

Timely Responsiveness: Excellent customer service requires responding promptly to customer needs and inquiries. Quick response times ensure timely resolution of issues and demonstrate that customers are valued and cared for.

Professional Knowledge: Good customer service entails having in-depth knowledge of products or services. Employees should possess excellent product knowledge and problem-solving abilities, providing accurate, clear information, and offering professional advice and assistance.

Friendliness and Politeness: Exceptional customer service is characterized by friendliness and respect towards customers. Employees should interact with customers in a friendly, polite manner, patiently listen to their needs and feedback, and treat every customer with sincerity.

Personalized Care: Outstanding customer service involves providing customized service tailored to individual customer needs and circumstances. Understanding customers’ preferences, purchase history, and special requirements allows for personalized recommendations and solutions, enhancing customer experience and satisfaction.

Continuous Improvement: Good customer service continuously strives for improvement. By collecting feedback and suggestions from customers, continuously refining service processes and solutions, businesses can enhance customer satisfaction and loyalty.

In summary, good customer service includes timely responsiveness, professional knowledge, friendliness and politeness, personalized care, and continuous improvement. By actively cultivating and practicing these qualities, businesses can build strong customer relationships, enhance competitiveness, and earn customers’ trust and support.

Frequently Asked Questions

What is BT laminate substrate, and why is it essential in electronic manufacturing?

BT laminate substrate, short for Bismaleimide Triazine laminate substrate, is a specialized type of material used in electronic manufacturing. It is composed of a blend of triazine resin and bismaleimide resin, renowned for its exceptional electrical properties, high-temperature resistance, and mechanical strength. Its significance lies in its ability to provide reliable performance and durability in electronic devices, ensuring stable operation even in demanding environments.

How is BT laminate substrate manufactured?

The manufacturing process of BT laminate substrate involves several steps. It starts with the preparation of raw materials such as triazine resin, bismaleimide resin, and glass fiber cloth. The cloth is pre-treated to enhance surface roughness, promoting better adhesion between the resin and fibers. Subsequently, the cloth is impregnated with a mixture of triazine and bismaleimide resins, stacked into layers, and subjected to high-temperature and pressure conditions for curing. Finally, the cured material is cut into the desired dimensions and shapes.

What are the advantages of using BT laminate substrate over other materials?

BT laminate substrate offers several advantages over alternative materials. Its outstanding electrical properties, including low dielectric loss and excellent signal transmission characteristics, make it ideal for high-frequency applications. Additionally, its high-temperature resistance ensures stability in harsh operating conditions, while its superior mechanical strength provides durability and reliability. These combined benefits make BT laminate substrate a preferred choice for demanding electronic applications.

In which industries or applications is BT laminate substrate commonly used?

BT laminate substrate finds widespread applications across various industries, including telecommunications, consumer electronics, industrial automation, and medical devices. It is commonly used in electronic components such as base stations, routers, smartphones, tablets, industrial control systems, sensors, medical monitors, and diagnostic equipment.

How can one procure BT laminate substrate?

BT laminate substrate can be obtained from electronic component suppliers and online marketplaces. Many specialized suppliers offer a range of specifications and models to suit different application requirements. Online platforms such as Alibaba and Amazon also provide convenient channels for purchasing high-quality BT laminate substrate.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier