Cavity PCB Manufacturing. Open Slot(cavity) on the PCBs, Control the depth of the cavity, use the High TG FR4 materials, or other High frequency high speed or ceramic materials.

In modern electronics, printed circuit boards (PCBs) play a vital role in ensuring the functionality and efficiency of electronic devices. Among various PCB manufacturing technologies, Cavity PCB technology stands out for its innovative approach that offers unique advantages in performance, reliability and miniaturization. In this comprehensive guide, we’ll delve into the intricacies of Cavity PCB technology manufacturing, exploring its key components, manufacturing processes, materials, cost factors, and the companies driving its development.

What is Cavity PCB Technology?

Cavity PCB Technology, also known as embedded component PCB or Cavity board, is an innovative PCB manufacturing technology that is significantly different from traditional PCB manufacturing methods. In traditional PCBs, electronic components are usually mounted on the surface of the substrate, but Cavity PCB Technology takes a different approach: embedding components within the layers of the PCB substrate.

The core of this technology is to achieve higher integration and more compact design by embedding components in the internal cavity of the PCB. Compared to traditional surface mount (SMT) methods, Cavity PCB Technology can accommodate more components in the same space while reducing the size and weight of the circuit board. This compact design can not only meet the needs of modern electronic products for thinness and miniaturization, but also improve the performance and reliability of electronic devices.

Cavity PCB Technology is suitable for various application scenarios with strict space and weight restrictions, such as aerospace, automotive, medical and communications fields. In these fields, electronic devices often need to integrate more functions and components in a limited space while maintaining good performance and reliability. By using Cavity PCB Technology, designers can overcome the space constraints faced by traditional surface assembly methods and achieve more efficient and reliable electronic system designs.

Generally speaking, Cavity PCB Technology is an innovative PCB manufacturing technology that achieves compactness, lightweight and high performance of electronic devices by embedding components into the internal cavity of the PCB substrate. In the ever-changing electronics industry, Cavity PCB Technology provides designers with a new solution to help them cope with increasingly complex design challenges and promote the progress and development of electronic technology.

Cavity PCB

How to design Cavity PCB?

Designing Cavity PCB is a complex and critical process that requires careful planning and comprehensive consideration of various factors. During this process, design engineers need to focus on key aspects such as component placement, thermal management, signal integrity and manufacturability to ensure that the final PCB design meets performance and reliability requirements.

First of all, component placement is one of the key steps in Cavity PCB design. Engineers need to carefully consider the placement of each component to minimize space on the board and ensure proper distance between components. Reasonable layout can not only optimize the performance of the circuit, but also simplify subsequent assembly and maintenance work.

Secondly, thermal management is crucial in Cavity PCB design. Due to the dense layout of electronic devices and the presence of high-power components, heat generation and conduction is a common challenge. Therefore, design engineers need to take effective measures to ensure that the circuit board maintains an appropriate temperature during operation to avoid damage to components or performance degradation caused by overheating.

In addition, signal integrity is also an aspect that needs to be focused on during the design process. Engineers must design trace paths precisely to minimize interference and loss during signal transmission. Using advanced PCB design software and simulation tools for signal integrity analysis can help engineers identify potential problems and make timely adjustments.

Finally, manufacturability is an important consideration in Cavity PCB design. Design engineers need to ensure that the circuit boards they design can be efficiently produced with existing manufacturing processes and equipment. Therefore, they need to take into account material availability, production process constraints, and manufacturer recommendations to ensure the design is manufacturable and implementable.

To sum up, designing Cavity PCB requires design engineers to consider comprehensively in terms of component placement, thermal management, signal integrity and manufacturability, and use advanced tools and technologies to optimize layout and routing to ensure the quality of the final design. Performance and reliability at their best.

What is the Cavity PCB manufacturing process?

The manufacturing process of Cavity PCB is a precise and complex process involving multiple key steps, each of which requires precise execution and strict quality control. Below are the main steps of Cavity PCB manufacturing process:

The first step in manufacturing Cavity PCB is to prepare the substrate. This includes selecting the appropriate substrate material, typically using high-quality fiberglass reinforced resin (FR-4) or other materials for specific requirements. Substrates must undergo rigorous inspection and cleaning to ensure the surface is smooth and free of dirt or residue.

Next, the multi-layer substrates are stacked together according to the design requirements. Each layer may contain layers with different functions such as circuit paths, signal layers, power layers, and ground layers. Through precise alignment and lamination technology, the connection and alignment between the layers are ensured.

Once the substrates are layered, cavities are created in the substrates using equipment such as CNC milling machines. These cavities are often used to embed components to achieve higher integration and performance. The milling process must be precisely controlled to ensure that the size and shape of the cavity meet the design requirements.

After the cavity milling is completed, the component is embedded into the cavity of the substrate. These components can be various electronic devices such as chips, resistors, capacitors, etc., which are embedded in the substrate to achieve compact design and optimized circuit layout. The embedding process requires a high degree of precision to ensure that components are installed correctly and well connected to the circuit.

After the components are embedded, the substrate of all layers is placed in a pressure and temperature controlled laminator. Through thermal pressure, good adhesion between substrate layers is ensured to form a complete Cavity PCB structure. The lamination process also helps eliminate air bubbles and improve the mechanical strength of the PCB.

Finally, the Cavity PCB is put through final finishing and inspection. This includes trimming edges, sanding surfaces, cleaning and inspecting connections. Any defects or defects need to be repaired or replaced promptly to ensure the quality and reliability of the final product.

Through the above steps, the Cavity PCB manufacturing process will be completed with the support of professional equipment and technology, ensuring the accuracy, consistency and reliability of the product. This highly-crafted manufacturing process lays a solid foundation for Cavity PCB’s performance and reliability, making it one of the important technologies in the electronics field.

How is Cavity PCB made?

The manufacturing of Cavity PCBs is a precise and complex process that requires the integration of advanced manufacturing technologies and processes to achieve superior quality and performance. From preparation of raw materials to final finishing, each step needs to be executed with care to ensure the final product meets the highest industry standards.

First, the process of manufacturing Cavity PCB begins with the selection and preparation of raw materials. High-quality substrate materials are one of the key factors to ensure PCB performance and reliability. Selecting the appropriate substrate material, such as FR-4, Rogers or high-frequency laminate, as well as other necessary materials and chemicals is a top priority to ensure a smooth manufacturing process.

Next comes the layering and layout stage. At this stage, layers of different materials are stacked together and laid out appropriately to accommodate circuit components and cavities, based on design requirements. Precise layering and layout are critical to ensure circuit stability and performance.

Then comes cavity machining and component embedding. Using advanced processing equipment, such as CNC milling machines and laser cutting machines, the substrate is cavity-processed to accommodate the components that need to be embedded. Subsequently, electronic components are precisely embedded into the cavity through automated assembly lines or specialized manual techniques, ensuring that they are tightly connected to the rest of the circuit board.

After the component embedding is complete, lamination and heat pressing are performed. Lamination is performed by subjecting multi-layer stacked substrates to high temperatures and pressures to ensure a strong bond between the layers while maintaining the flatness and stability of the board. The hot pressing process also helps remove any remaining air bubbles that may be present, ensuring the quality and reliability of the circuit board.

Finally comes the final finishing and inspection. At the final stage of the manufacturing process, the manufactured Cavity PCB is subjected to surface treatment, cutting, drilling and other final finishing work to meet the customer’s specific requirements. At the same time, through strict quality control measures and inspection processes, we ensure that each product meets the highest quality standards and specification requirements.

Overall, manufacturing Cavity PCB requires integrating advanced manufacturing technologies and processes to ensure product quality, performance and reliability. Through carefully designed processes and strict quality control measures, manufacturers are able to achieve precise control of the Cavity PCB manufacturing process to meet customer needs and promote industry development and innovation.

What are the cost considerations for Cavity PCB?

Cost considerations for Cavity PCB run the gamut, and while it offers unparalleled advantages in performance and miniaturization, it can be more expensive to manufacture than a traditional PCB. The following are the key factors that affect the total cost of Cavity PCB manufacturing:

The material selection of a Cavity PCB has a significant impact on its manufacturing cost. High-performance materials such as high-frequency laminates and special substrates are usually more expensive, but can meet the requirements of complex circuits and improve product performance and reliability. In addition, considering the design requirements and application scenarios, the quality and performance of the materials will also affect the cost.

The design complexity of Cavity PCB is one of the important factors that determine its manufacturing cost. Cavity PCBs with high design complexity may require more engineers and design time to complete layout, routing and analysis. In addition, complex designs may require special processes and processing techniques, further increasing manufacturing costs.

Production volume is another key factor affecting Cavity PCB manufacturing costs. Typically, larger batch production can achieve economies of scale and reduce the cost of a single PCB. In contrast, low-volume production may result in fixed costs being spread unevenly, thereby increasing the cost per PCB.

Cavity PCB manufacturing may require the use of advanced technologies and equipment, such as laser drilling, film covering, multi-layer stacking, etc. These technical requirements may increase the investment and operating costs of manufacturing equipment and may require specialized technicians for operation and maintenance. Therefore, technical requirements have a direct impact on the total cost.

To sum up, the manufacturing cost of Cavity PCB is affected by many factors, including material selection, design complexity, production volume and technical requirements. During the manufacturing process, comprehensive consideration of these factors and taking effective cost control measures will help reduce the total cost of Cavity PCB while ensuring the improvement of product quality and performance.

What materials are used in Cavity PCB?

Cavity PCB is a special type of printed circuit board with embedded components, and its manufacturing process and material selection are crucial. In Cavity PCB manufacturing, the materials used are critical to the performance, stability and reliability of the circuit board. The main Cavity PCB materials include FR-4, Rogers and high frequency laminates.

FR-4 is a common fiberglass reinforced epoxy resin material with excellent electrical insulation properties and mechanical strength. It is widely used in conventional circuit board manufacturing and is also one of the commonly used materials for Cavity PCB. FR-4 material has good heat resistance and chemical stability and is suitable for applications in various environmental conditions.

Rogers is a well-known manufacturer of high-performance materials, offering a variety of specialty laminates for microwave and radio frequency applications. These sheets have excellent dielectric properties, low loss and high frequency performance, making them ideal for applications such as high frequency communications and radar systems. In Cavity PCB manufacturing, Rogers materials provide superior signal integrity and circuit performance.

High frequency laminate is a material specifically designed for RF and microwave circuit applications that has excellent dielectric properties and frequency stability. These materials are usually made of high-performance plastics such as polytetrafluoroethylene (PTFE), which can meet the requirements of high-frequency circuits for low loss and high-speed transmission. In Cavity PCB manufacturing, high-frequency laminates can ensure the high-frequency performance and stability of circuits and are suitable for applications in wireless communications, satellite navigation, and medical diagnostics.

In general, the materials used in Cavity PCB manufacturing have excellent electrical properties, thermal stability and mechanical strength, and can meet the needs of various industries for high-performance circuit boards. The selection and application of these materials provide Cavity PCB with a reliable foundation in demanding application scenarios in the fields of aerospace, automotive, medical and communications, and promote the continuous innovation and development of electronic technology.

Who are the leading manufacturers of Cavity PCB?

Cavity PCB manufacturing is a complex and precise process that involves multiple critical steps and specialized techniques to ensure the final product is of the highest standard of quality and performance. The main contents of Cavity PCB manufacturing will be introduced in detail below:

Substrate preparation: The first step in Cavity PCB manufacturing is to prepare the substrate. This includes selecting the appropriate substrate material, typically FR-4 or other high-frequency laminates, and performing the necessary surface treatments, such as chemical cleaning and surface coating, to ensure good adhesion.

Stacking: Next, multiple layers of substrates are stacked together to form the overall structure. These layers usually include copper foil layers and dielectric layers, which are bonded together through a lamination process to form a complete substrate structure.

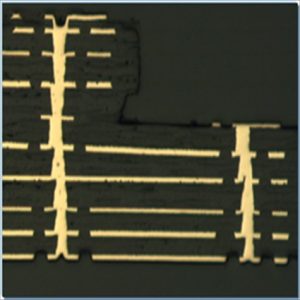

Cavity Milling: During the Cavity PCB manufacturing process, cavity milling is necessary to create a cavity inside the substrate. These cavities are used to embed electronic components to enable compact designs and optimized layouts.

Component Embedding: After the cavity is formed, the electronic components are embedded into the inner layers of the substrate. These components can be various packaged chips, resistors, capacitors, etc., which are precisely positioned and fixed inside the substrate to ensure stability and reliability.

Lamination: After embedding the components, the substrate is placed in a laminator for lamination. This process involves laminating all the layers together and applying high pressure and temperature to ensure bonding and sealing between the layers.

Final Finishing: Finally, final finishing is performed, including cleaning, inspection, and testing. At this stage, Cavity PCB is subject to strict quality control to ensure compliance with specifications and customer requirements.

As a professional Cavity PCB manufacturer, we have advanced production equipment and rich experience, able to provide customers with high-quality customized solutions. We are committed to continuous improvement and innovation to meet our customers’ ever-changing needs and ensure their projects receive optimal performance and reliability.

What are the qualities of good customer service?

In Cavity PCB manufacturing, excellent customer service is critical to ensuring customer satisfaction and loyalty. To achieve this, manufacturers need to possess a number of key attributes that build great relationships and drive long-term success. Here are the key qualities of good customer service:

Good customer service starts with effective communication. Manufacturers should actively listen to customer needs and communicate timely information about order progress, technical issues, and project updates. Through clear, timely, and transparent communication, a foundation of trust and cooperation can be built.

Customers expect to receive a timely response when they ask questions or make demands. Manufacturers should remain flexible and responsive, promptly resolving customer issues and providing support to ensure customer satisfaction and smooth project progress.

In the field of Cavity PCB manufacturing, technical expertise is crucial. Manufacturers should have deep technical strength and expertise to understand customer needs and provide corresponding solutions. By providing customers with professional technical support and advice, manufacturers can enhance customer trust and improve customer satisfaction.

Reliability is one of the key elements of good customer service. Manufacturers need to reliably execute on their promises, such as delivering orders on time, providing high-quality products and services, and providing timely support and solutions when customers encounter problems. By maintaining reliability, manufacturers can build a good reputation and gain customer trust.

In the Cavity PCB manufacturing process, quality is of the utmost importance. Manufacturers should be responsible for product quality and strictly follow quality control standards and processes. By continuously improving product quality and continuously improving manufacturing processes, manufacturers can ensure that the products delivered to customers meet high standards, thereby increasing customer satisfaction and trust.

To sum up, good customer service is crucial for Cavity PCB manufacturers. Through key attributes such as effective communication, responsiveness, technical expertise, reliability and commitment to quality, manufacturers can build strong relationships with customers, drive long-term success and gain a competitive advantage in the market.

Frequently Asked Questions

How can I select the right manufacturer for my Cavity PCB project?

When choosing a manufacturer for your Cavity PCB project, it is essential to consider several factors, including the manufacturer’s experience and expertise in Cavity PCB manufacturing, their capabilities and facilities, their quality control processes, their track record of delivering projects on time and within budget, and their customer service and support. It is advisable to request samples, review case studies, and obtain references from previous clients to assess the manufacturer’s capabilities and reputation. Additionally, engaging in open communication and discussing project requirements, expectations, and timelines upfront can help ensure a successful partnership and project outcome.

What are the primary benefits of using Cavity PCB Technology?

Cavity PCB Technology offers several key advantages, including enhanced miniaturization, improved thermal management, reduced electromagnetic interference (EMI), and increased reliability. By embedding components within the PCB substrate, Cavity PCBs enable the creation of compact and lightweight electronic devices with optimized performance and functionality. Additionally, the integrated design minimizes signal distortion and improves signal integrity, making Cavity PCBs ideal for high-frequency and high-speed applications.

How does Cavity PCB Technology differ from conventional PCB manufacturing?

Unlike conventional PCB manufacturing, which involves mounting components on the surface of the board, Cavity PCB Technology embeds components within the layers of the PCB substrate. This innovative approach eliminates the need for bulky external components and reduces the overall size and weight of the electronic device. Furthermore, Cavity PCBs offer superior thermal dissipation properties, enhanced signal integrity, and improved reliability compared to traditional PCBs, making them suitable for a wide range of demanding applications.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier