Cavity Substrate| Package substrate manufacturing , we mainly produce ultra-small bump pitch cavity substrate, ultra-small trace and spacing package substrates from 4 layer to 20 layers.

In today’s digital age, where electronics have penetrated into every aspect of our lives, understanding the complexities of cavity substrate manufacturing (CSM) has become critical. Although CSM is ubiquitous in modern electronics, the manufacturing process behind it remains mysterious to many. This comprehensive guide aims to demystify the mystery surrounding CSM and is tailor-made for beginners eager to master the essentials.

What is CSM?

CSM (Cavity Substrate Manufacturing) is a specialized printed circuit board (PCB) manufacturing technology designed to embed cavities or grooves to accommodate specific components or systems. These custom substrates not only provide mechanical support but also provide electrical connections through precisely placed wires, optimizing electronic device performance and space utilization.

In traditional PCB design, electronic components are usually surface mounted on one side of the board, giving the entire circuit board a relatively thin structure. However, for some applications, such as radio frequency (RF) or microwave systems, more complex layouts and denser arrangements of components are required. This is where CSM technology comes in.

Through CSM, designers can create cavities inside the PCB, which can accommodate specific components, such as radio frequency modules, microwave antennas, etc. This design makes the electronic system more compact and reduces the length of the signal transmission path, thereby reducing the risk of signal attenuation and interference and improving system performance and stability.

In addition, CSM can also improve heat dissipation performance. By embedding a heat sink or other thermal management component into the cavity, CSM technology can dissipate heat more effectively, lower the operating temperature of electronic components and extend their service life.

Overall, CSM technology brings new possibilities and flexibility to the design of electronic devices. By embedding custom cavities and grooves, designers can achieve higher performance, more compact electronic systems to meet growing market demands and application requirements.

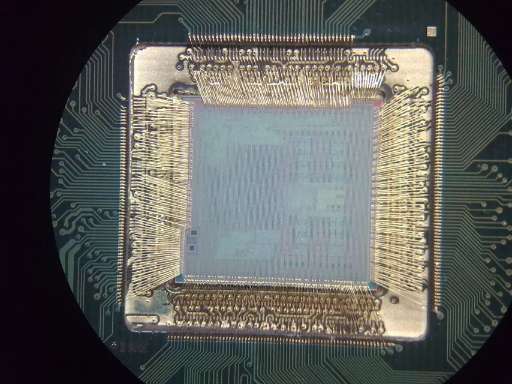

Cavity Substrate

How to design a cavity substrate?

Designing the cavity substrate is a critical stage that requires careful planning and execution. First, the designer needs to start with a conceptual layout. This means careful consideration of the size and shape of the cavity and how components are arranged. By considering circuit functionality and space utilization, designers can determine the optimal cavity layout to meet product requirements and performance needs.

After the conceptual layout is determined, the next step is to precisely place the components within the cavity. This involves selecting the appropriate components and placing them within the cavity to ensure they can connect with the surrounding circuitry and work efficiently. During this process, designers need to consider factors such as spacing between components, heat dissipation and signal interference to ensure that the final cavity substrate can achieve the expected performance specifications.

Utilizing advanced CAD software such as Altium Designer or Mentor Graphics is one of the key tools for designing cavity substrates. These software provide a rich set of features and tools that enable designers to easily perform schematic capture, layout design and verification. With these software, designers can quickly and accurately create cavity substrate designs while performing circuit simulation and verification to ensure design accuracy and reliability.

During the schematic capture phase, the designer will draw a schematic of the circuit and determine where the cavities are located and how they are connected. The layout design phase involves placing components in cavities and determining routing paths between them. Designers need to consider the size and shape of the cavity, as well as the electrical and mechanical connections between components. Finally, during the validation phase, designers will simulate and test the design to ensure that the cavity substrate’s performance and reliability are as expected.

In general, designing cavity substrates is a complex and critical process, which requires designers to have deep technical skills and rich experience. Through careful planning and the utilization of advanced CAD software, designers can create cavity substrates with superior performance to meet the needs and requirements of various electronic products.

What is the manufacturing process of CSM?

The manufacturing process of CSM is a precise and complex process designed to provide optimal performance and reliability for electronic devices. The following are the detailed steps of the cavity substrate manufacturing process:

The first step in fabricating a cavity substrate is to prepare the substrate material. A commonly used material is a ceramic-filled polymer substrate due to its excellent insulating properties and good thermal conductivity. Substrate preparation includes cleaning, cutting and surface preparation to ensure good adhesion and stability.

Next is the creation of cavities in the substrate through specialized milling or cutting techniques. These cavities can be customized to accommodate specific electronic components or systems based on specific design requirements. In this step, the processing parameters need to be precisely controlled to ensure that the size and shape of the cavity meet the design specifications.

Once the cavity is formed, the next step is to deposit a copper layer on the surface of the substrate. Copper is an excellent conductive material used to connect electronic components and form wires. Copper deposition is usually achieved by chemical methods or electroplating techniques to ensure that the copper layer is uniform, firmly adhered, and has good electrical conductivity.

Finally, surface treatment is required to complete the cavity substrate manufacturing process. Surface preparation includes the application of protective coverings (such as pad coverage) and final inspection and testing. These steps help improve the durability, corrosion resistance and environmental stability of the cavity substrate, ensuring it performs well in a variety of application scenarios.

Throughout the entire manufacturing process, strict quality control and inspection procedures are indispensable. Manufacturers must ensure that design specifications are met at every step and that any potential issues are identified and corrected promptly. Only in this way can we produce high-quality, reliable cavity substrates that meet customer needs and expectations.

Through the above steps, the cavity substrate manufacturing process will fully demonstrate its precision and professionalism. Each step requires experienced technicians and advanced equipment to ensure the highest level of quality and performance of the final product.

How is the fabrication of cavity substrates performed?

Once the design is finalized, the files are sent to the trusted CSM manufacturer, which marks the beginning of the critical phase of cavity substrate fabrication. These manufacturers have advanced resources and expertise in technology and equipment to implement the details and requirements specified in the design documents. Their factory equipment covers a full range of technologies from CAD software conversion to actual physical production, including advanced automated machines and strict quality control measures.

After receiving the design documents, the CSM manufacturer first conducts a document review to ensure the completeness and consistency of the design. After confirming that the design documents are accurate, the manufacturer will begin preparing the materials and equipment required for manufacturing. This may include selecting the appropriate substrate material, preparing the work area, setting up the production line, and preparing processing tools and equipment.

The manufacturer will then begin the actual manufacturing process. This process is usually divided into several key steps, including substrate preparation, cavity processing, circuit routing, soldering and surface treatment. Each step requires a high degree of precision and expertise to ensure the final product meets design specifications and has stable performance.

During the substrate preparation stage, the manufacturer will prepare the substrate material and perform necessary cleaning and coating processes. Next, the cavity machining stage is a critical step, where manufacturers will use specialized milling or cutting equipment to precisely form cavities in the substrate. This requires a high degree of technical ability and experience to ensure that the size and shape of the cavity meet the design requirements.

Once the cavity is machined, the manufacturer moves on to laying out circuit traces and soldering to secure the electronic components to the substrate. This process requires precise operation and a high degree of patience to ensure the reliability and stability of the circuit connection. Finally, manufacturers will perform surface treatments, such as applying a protective coating or adding logos, to improve the durability and appearance of the substrate.

Throughout the manufacturing process, manufacturers strictly follow quality standards and schedules to ensure product quality and delivery time. They perform multiple quality checks and tests to ensure that each cavity substrate meets customer requirements and expectations. Through these efforts, CSM manufacturers are able to provide high-quality, reliable cavity substrates that meet customer needs and remain competitive.

Find out how much cavity substrates cost?

The cost of the cavity substrate is a key consideration and is affected by a variety of factors, including substrate material, cavity complexity and manufacturing volume. First of all, substrate material is one of the main factors affecting cost. Different types of materials have different costs. For example, ceramic-filled polymer substrates are relatively expensive, while ordinary FR-4 substrates are relatively cheaper. Second, the complexity of the cavity also affects cost. If the cavity has a complex shape or requires highly precise machining, the manufacturing cost will increase accordingly. Finally, manufacturing volume is also an important consideration. Generally speaking, the cost of high-volume production will be relatively low because manufacturers can reduce costs through economies of scale.

Although cavity substrates may have a mid-to-high price tag, the enhanced performance and space optimization benefits they bring can often justify the investment. First, cavity substrates can provide better thermal management capabilities. By integrating a heat sink or other thermal management solution into the cavity, the cavity substrate can effectively dissipate heat, improving the performance and reliability of electronic devices. Secondly, cavity substrates can reduce electromagnetic interference (EMI). By placing sensitive components in the cavity, interference between electronic devices can be reduced and their working stability improved. In addition, cavity substrates enable space optimization. By placing components in the cavity, valuable space is saved, making electronic devices more compact and lightweight.

In summary, while cavity substrates may come at a cost, the investment is often worth it given the enhanced performance and space optimization benefits they bring. For electronic device manufacturers who require high performance and reliability, choosing a cavity substrate can be a wise choice.

What materials are used in CSM?

The materials used in Cavity Substrate Manufacturing (CSM) are critical and directly impact the performance and reliability of the cavity substrate. Here are some common materials and their role in CSM:

Polymer substrates are one of the basic building blocks of CSM. They provide basic mechanical support and mounting surfaces for electronic components. During the cavity substrate manufacturing process, commonly used polymer substrates are filled with ceramic particles to improve the mechanical strength and thermal properties of the substrate. This filler material makes the substrate more durable and able to withstand higher temperatures and environmental challenges while maintaining stable size and shape.

In CSM, copper is widely used in the manufacture of conductive lines. Copper has excellent electrical conductivity properties and good processability, making it ideal for manufacturing electronic components. During the cavity substrate manufacturing process, copper is precisely deposited on the substrate surface and chemically or mechanically processed to form complex conductive paths to connect various components and circuits.

In addition to ceramic-filled polymer substrates and copper conductive traces, CSM requires the use of advanced dielectric materials for insulation and thermal management. These materials have good insulating properties and can effectively isolate conductive paths and avoid circuit short circuits and interference. At the same time, they also have excellent thermal conductivity properties, helping to disperse and manage heat in electronic devices, improving overall performance and reliability.

In summary, ceramic-filled polymer substrates, copper conductive traces, and advanced dielectric materials for insulation and thermal management are indispensable key materials in Cavity Substrate Manufacturing. Together they form the basic structure of the cavity substrate and ensure the stability, performance and reliability of electronic devices. By selecting appropriate materials and precision manufacturing, CSM can achieve a higher level of design flexibility and electronic system integration, driving the development and innovation of modern electronic technology.

Who are the key players in CSM manufacturing?

In the Cavity Substrate Manufacturing (CSM) ecosystem, key players play a vital role, and every stage from design to production is inseparable from their contributions. One of the most important players is the manufacturer, who is the core driving force in the CSM manufacturing process.

Manufacturers play multiple roles in the CSM industry. They are not only manufacturers of cavity substrates, but also leaders in technological innovation and customer service. Following are their key roles in CSM manufacturing:

Technical Experts: Manufacturers have extensive technical knowledge and experience and are able to provide state-of-the-art manufacturing technologies and solutions. Their in-depth understanding of material properties, process flows and best practices ensures the production of high-quality cavity substrates.

Customized Services: Manufacturers are able to provide customized solutions as per the customer’s needs and specifications. Whether it is complex design requirements or specific application scenarios, they are able to flexibly adjust the production process to meet customers’ individual needs.

Quality Control: Manufacturers are committed to product quality and consistency. They adopt strict quality control measures and conduct strict inspection and testing in every aspect from raw material procurement to final delivery to ensure that the products meet customer requirements and standards.

Innovation-driven: Manufacturers continue to pursue technological innovation and progress and promote the development and change of the industry. They invest significant resources in research and development to explore new materials, processes and technologies to meet changing market needs and customer expectations.

Customer support: A close cooperative relationship has been established between the manufacturer and its customers, providing a full range of customer support and services. Whether it is technical consultation, production progress tracking or after-sales support, they always stand in the customer’s position, actively solve problems and provide help.

Production capacity: Manufacturers have advanced production equipment and processes that can meet production needs of different scales and complexity. They have efficient production capabilities and flexible production scheduling, enabling timely delivery of high-quality products.

In general, manufacturers are one of the key players in the CSM manufacturing process. They contribute to the continued development of the industry and successful cooperation with customers through technical expertise, customized services, quality control, innovation drive, customer support and production capabilities. made important contributions. In CSM manufacturing, choosing the right manufacturer is a critical step in ensuring project success.

What are the characteristics of excellent customer service in CSM?

In Cavity Substrate Manufacturing (CSM), excellent customer service is a key factor in ensuring customer satisfaction and business success. The following are the key attributes of great customer service in CSM:

In the CSM manufacturing process, timely and effective communication is crucial to meeting customer needs. A good customer service team should be able to respond quickly to customer queries, feedback or concerns and provide clear solutions.

Having in-depth industry knowledge and technical expertise is the foundation for providing excellent customer service. The customer service team should understand the customer’s needs and challenges and be able to provide professional advice and guidance to ensure smooth progress and successful delivery of the project.

CSM projects often face changes in customer requirements and project specifications. A good customer service team should be flexible and able to adapt to these changes and adjust plans and resources in a timely manner to meet customer requirements.

Providing high-quality cavity substrates that meet or exceed industry standards is at the core of excellent customer service. The customer service team should work closely with the manufacturing team to ensure that each item undergoes strict quality control and testing to ensure product reliability and performance.

Clear and transparent pricing, timelines and project updates are key to building customer trust and confidence. A quality customer service team should provide customers with detailed quotations and project plans, and regularly update customers on the progress of their projects to ensure that customers always understand the project’s status and expected delivery time.

In the world of CSM, these key attributes are integral to providing excellent customer service. Through prompt response, expertise, flexibility, quality assurance and transparency, the customer service team builds great relationships and ensures customer satisfaction and confidence in their cavity substrate manufacturing projects.

Frequently Asked Questions

What are the primary advantages of using cavity substrates in electronic design?

Cavity substrates offer several significant advantages in electronic design. Firstly, they enable enhanced thermal management by providing a dedicated space for heat-generating components, thus preventing overheating and ensuring optimal performance. Secondly, cavity substrates help reduce electromagnetic interference (EMI) by isolating sensitive components within the cavity, resulting in improved signal integrity and reliability. Additionally, cavity substrates contribute to enhanced mechanical stability, protecting delicate components from external shocks or vibrations. Overall, the integration of cavity substrates in electronic design leads to improved performance, reliability, and longevity of electronic devices.

How long does it typically take to manufacture custom cavity substrates?

The manufacturing lead time for custom cavity substrates can vary depending on several factors, including the complexity of the design, the volume of production, and the specific requirements of the project. In general, the process of manufacturing custom cavity substrates involves multiple steps, such as substrate preparation, cavity formation, copper deposition, and surface finishing, each of which requires careful attention to detail and precision. As a result, the manufacturing lead time may range from several weeks to a few months, with larger volumes and more complex designs typically requiring longer lead times to ensure quality and accuracy.

Are there any environmentally friendly practices in cavity substrate manufacturing?

Yes, many manufacturers of cavity substrates have implemented environmentally friendly practices to reduce their environmental impact. These practices may include the use of recyclable materials in substrate fabrication, such as eco-friendly PCB substrates or biodegradable packaging materials. Additionally, some manufacturers have adopted energy-efficient manufacturing processes to minimize their carbon footprint and reduce waste generation. By incorporating these environmentally friendly practices into cavity substrate manufacturing, companies can contribute to sustainability efforts and reduce their overall environmental impact.

What are the key considerations when selecting a CSM manufacturer?

When selecting a CSM manufacturer, several key considerations should be taken into account to ensure the successful execution of your project. Firstly, evaluate the manufacturer’s experience and expertise in cavity substrate manufacturing, including their track record of delivering high-quality products and meeting customer requirements. Secondly, consider the manufacturer’s capabilities and resources, such as their manufacturing facilities, equipment, and workforce, to determine if they can accommodate your project’s specific needs and volume requirements. Additionally, assess the manufacturer’s quality assurance processes and certifications to ensure compliance with industry standards and regulations. Finally, consider factors such as lead times, pricing, and customer support to ensure a smooth and satisfactory manufacturing experience.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier