Embedded Cavity PCB Substrate Manufacturer, Embedded Components/IC PCB, Embedded slot PCB and Depth control Cavity PCBs manufacturing.

The Embedded Cavity PCB Substrate represents cutting-edge technology in PCB (Printed Circuit Board) engineering, providing an innovative design tailored to the compact, efficient, and high-performance requirements of contemporary electronic devices. Unlike conventional PCBs, this advanced substrate incorporates strategically designed embedded cavities to enhance thermal management and optimize electrical performance.

The incorporation of embedded cavities serves a dual function. Firstly, it effectively tackles the growing heat generation in contemporary electronic devices by providing extra surfaces for heat dissipation. This promotes the efficient dispersion of heat, ensuring that the device functions at a lower temperature, consequently improving stability and reliability.

This reduction in interference leads to improved signal transmission quality, ultimately optimizing the electrical performance of the device.

Moreover, the innovative design not only serves functional purposes but also allows for stylish and lightweight device designs. In contrast to the bulkiness of traditional PCBs, the embedded cavity design makes the substrate more compact, resulting in sleek and lightweight electronic products that align with the aesthetic preferences of modern consumers.

Through strategically embedded cavities, it addresses thermal management challenges, optimizes electrical performance, and provides opportunities for stylish and lightweight device designs—a significant advancement in the field of PCB engineering.

What types of Embedded Cavity PCB Substrate are there?

Embedded Cavity PCB Substrate is an innovative design featuring an embedded cavity structure, offering crucial support for thermal management, electrical performance, and overall electronic device design. This substrate is categorized into three main types:

Based on organic materials, providing versatility and excellent performance.

Advantages include flexibility and cost-effectiveness, making it suitable for diverse projects.

Ceramic Substrate

Made from advanced ceramic materials to achieve superior thermal conductivity and stability.

Ideal for high thermal management requirements in applications such as high-power electronics and radio frequency modules.

Key advantage is excellent thermal conductivity, effectively dispersing heat and maintaining equipment stability.

Silicon Substrate

Utilizes silicon material advantages to enhance electrical characteristics.

Commonly employed in applications requiring high-frequency, high-speed signal transmission, such as communications equipment and data center servers.

Key advantage is excellent electrical properties, ensuring stable signal transmission and high-speed processing.

In summary, Embedded Cavity PCB Substrate encompasses three types: organic, ceramic, and silicon substrates. Each type offers unique advantages and is suitable for specific scenarios, allowing for the selection of the most appropriate type based on project requirements.

What are the advantages of Embedded Cavity PCB Substrate?

Embedded Cavity PCB Substrates is an innovative PCB substrate design whose unique structure and characteristics bring many advantages to electronic devices. Here are a few significant benefits of using Embedded Cavity PCB Substrates:

Efficient thermal management

With embedded cavities and optimized thermal conductivity materials, this substrate can quickly remove heat from critical components, ensuring that the device maintains a stable temperature over long periods of operation.

Optimized electrical performance

Maintaining stable electrical performance is crucial for the dependable functioning of electronic devices. Embedded Cavity PCB Substrates play a vital role in ensuring signal integrity and stability by minimizing electrical noise during signal transmission and safeguarding critical circuits from external interference. Their precision design and use of high-quality materials guarantee highly reliable signal transmission, meeting the demanding standards of high-performance electronic equipment.

Compact and lightweight design

Modern electronic equipment pays more and more attention to lightness and portability, and compact and lightweight design is another advantage of Embedded Cavity PCB Substrates. Through careful space utilization and optimized layout, this substrate can achieve smaller device designs and meet the market demand for small and lightweight electronic devices. Therefore, Embedded Cavity PCB Substrates not only provide superior performance but also bring huge advantages to the appearance and portability of the device.

Improved reliability and durability

Embedded Cavity PCB Substrates are designed to meet the escalating demands for reliability and durability in modern electronic products. Leveraging a precision manufacturing process and meticulous material selection, these substrates guarantee stability and longevity. They not only withstand environmental factors but also sustain consistent performance over time, aligning with the rigorous standards of contemporary electronics.

To sum up, Embedded Cavity PCB Substrates provide strong support and guarantee for the development of modern electronic equipment with its efficient thermal management, optimized electrical performance, compact and lightweight design, and improved reliability and durability.

Why choose Embedded Cavity PCB Substrate?

Design engineers and manufacturers are increasingly opting for Embedded Cavity PCB Substrates over traditional PCB boards due to their notable advantages, particularly in thermal dissipation. In high-performance electronic devices, effective thermal management is critical. Unlike traditional PCBs that can generate significant heat during operation, Embedded Cavity PCB Substrates excel in promoting the transfer and dissipation of heat through strategically designed embedded cavities. This capability ensures that electronic components operate within the designated temperature range, ultimately enhancing equipment stability and reliability.

In modern electronic devices, compactness in size and weight is an important consideration. Traditional PCB boards may take up a lot of space, but Embedded Cavity PCB Substrates effectively reduce the size of components through their exquisite design, allowing them to easily fit into various compact equipment designs, thereby increasing product flexibility and Customizability.

Finally, Embedded Cavity PCB Substrates demonstrate superior performance in harsh environments. Whether in extreme temperature, humidity or vibration environments, this special substrate is able to maintain a stable working condition and protect electronic components from the external environment. This makes Embedded Cavity PCB Substrates the first choice in many key application areas, such as aerospace, automotive electronics and industrial control.

Therefore, Embedded Cavity PCB Substrates are increasingly favored by design engineers and manufacturers due to their excellent heat dissipation capabilities, small form factor, and excellent performance in harsh environments. Whether you are pursuing higher performance, smaller size, or more reliable and stable electronic devices, choosing Embedded Cavity PCB Substrates is a wise choice.

What is the manufacturing process of Embedded Cavity PCB Substrate?

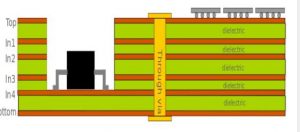

In the modern electronics industry, Embedded Cavity PCB Substrate manufacturing is a critical link, ensuring seamless integration and excellent performance. This process includes two main stages: motherboard manufacturing and substrate manufacturing.

Motherboard manufacturing

The motherboard is the core of Embedded Cavity PCB Substrate manufacturing. At this stage, the basic structure of the motherboard needs to be designed and manufactured first, including circuit layout and cavity design. The circuit patterns and other key components are then embedded into the motherboard through advanced manufacturing techniques such as printing, layer stacking, and electroplating. This ensures the accuracy and consistency of the embedded cavity, laying a solid foundation for subsequent steps.

Substrate manufacturing

The manufacturing process of Embedded Cavity PCB Substrate involves intricate procedures that demand precise material selection, advanced technology, and stringent quality control measures. Initially, a suitable substrate material, such as organic, ceramic, or silicon-based, is chosen to meet specific application requirements. The substrate undergoes processing to achieve the desired shape and size using advanced techniques like laser cutting and CNC machining. Throughout the processing, each step is closely monitored to ensure the final product’s performance and reliability. Subsequently, quality inspection and testing are conducted to validate that the Embedded Cavity PCB Substrate meets specifications.

The realization of Embedded Cavity PCB Substrate occurs through two primary stages: motherboard manufacturing and substrate manufacturing. This process establishes a dependable foundation for contemporary electronic devices. The precision and complexity of this manufacturing process underscore the electronics industry’s continuous pursuit of high-quality, high-performance products.

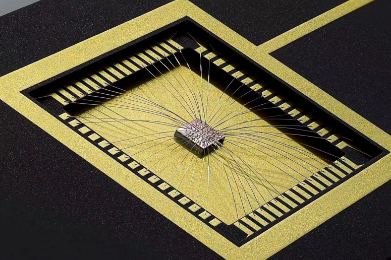

Embedded Cavity PCB

What are the application areas of Embedded Cavity PCB Substrate?

Embedded Cavity PCB Substrate is a versatile technology widely employed across diverse industries. Its remarkable thermal management and electrical performance establish a stable foundation for these products.

Within the automotive sector, the escalating demand for electronic components necessitates the adoption of Embedded Cavity PCB Substrate to ensure reliability and high performance in critical systems such as in-car entertainment, navigation, and engine control units. Its exceptional reliability and durability make it the preferred choice for automotive electronics, meeting stringent environmental requirements.

Embedded Cavity PCB Substrate plays a crucial role in maintaining stringent standards in medical devices, where stability, accuracy, and reliability are paramount for applications related to human life and health. This specialized substrate is instrumental in ensuring the performance and safety of medical equipment such as pacemakers, imaging devices, and implantable medical devices.

In the field of telecommunications, Embedded Cavity PCB Substrate is also employed to enhance the performance of communication systems through optimized PCB design. Whether utilized in base station equipment, communication network devices, or satellite communication equipment, the substrate’s capabilities in high-speed signal transmission and efficient thermal management make it an ideal choice for meeting the complex requirements of the telecommunications industry.

In summary, Embedded Cavity PCB Substrate finds widespread use in consumer electronics, automobiles, medical equipment, telecommunications, and other sectors. Its outstanding performance and reliability establish it as an indispensable technology in the design of modern electronic products.

Where can I find Embedded Cavity PCB Substrate?

When searching for reliable Embedded Cavity PCB Substrate manufacturers and suppliers, it is essential to explore both regional and global options for a comprehensive selection. In the fast-paced evolution of this industry, finding trustworthy suppliers is paramount, and our company stands out as the professional manufacturer you seek.

Collaborating with us presents several advantages:

Professional Technical Support: Our experienced technical team is ready to provide expert support and consultation services.

High-Quality Products: We employ cutting-edge production techniques and a rigorous quality control system to guarantee stable and reliable product quality.

We offer adaptable production capabilities, enabling us to undertake customized small-batch production to cater to your specific requirements, ensuring diverse solutions to meet your needs. Our competitive pricing ensures you receive top-quality products at reasonable rates, delivering excellent value for your investment. Regardless of your location, we extend comprehensive support and services, instilling confidence in entrusting your project to us for satisfactory outcomes. Reach out to us to explore our products and services further; we eagerly anticipate the opportunity to collaborate with you!

How much does Embedded Cavity PCB Substrate cost?

When seeking Embedded Cavity PCB Substrates, it is essential to grasp the cost factors and key considerations involved in their quotations. An accurate quote not only empowers customers to make informed decisions but also ensures project feasibility and successful implementation.

Material Cost:The cost of Embedded Cavity PCB Substrates is heavily influenced by the choice of materials. Ceramic substrates, for example, are more expensive compared to organic substrates due to their superior thermal conductivity and resistance to high temperatures.

Manufacturing Process:The production of Embedded Cavity PCB Substrates involves intricate processes like cutting, perforation, and immersion gold application. Each step in the manufacturing process contributes to the overall costs, and the complexity of the process directly affects the final quoted price.

Technical Requirements:High-performance Embedded Cavity PCB Substrates may necessitate the utilization of advanced technology and equipment during manufacturing, leading to increased production costs.

Quantity and size: Order quantity and size also have an important impact on quotations. Generally speaking, large-volume orders can enjoy lower unit prices, while small-volume orders may require higher costs.

Key considerations

Consideration of Embedded Cavity PCB Substrate should go beyond just the price, emphasizing both quality and performance. Opting for products with reliable quality and superior performance is crucial for the long-term success of your project.

When evaluating quotes, take into account lead times; while fast delivery may incur additional costs, it’s essential to balance cost and urgency based on project timelines.

In supplier selection, factor in the technical support and consulting services offered. Quality technical support can assist in problem-solving during production, enhancing efficiency, and ensuring product quality.

In summary, understanding the quote for Embedded Cavity PCB Substrate requires considering cost factors and key considerations. By fully communicating with suppliers and comparing quotes from different suppliers, customers can make informed decisions to ensure the smooth progress and success of the project.

Embedded Cavity PCB

Embedded Cavity PCB Substrate FAQS

What is the manufacturing process for Embedded Cavity PCB Substrates?

The manufacturing process for Embedded Cavity PCB Substrates involves several steps, including motherboard manufacturing and substrate manufacturing. Motherboard manufacturing encompasses the integration of embedded cavities into the design, while substrate manufacturing involves material selection, advanced techniques, and quality control measures to ensure optimal performance.

How are Embedded Cavity PCB Substrates manufactured?

The manufacturing process of Embedded Cavity PCB Substrates involves intricate procedures, including motherboard manufacturing and substrate manufacturing. Motherboard manufacturing ensures seamless integration, while substrate manufacturing encompasses material selection, advanced techniques, and stringent quality control measures.

Where can one find Embedded Cavity PCB Substrate manufacturers?

Reputable Embedded Cavity PCB Substrate manufacturers and suppliers can be found globally. It’s essential to explore both regional and global sources to obtain a comprehensive selection and ensure quality and reliability.

How are Embedded Cavity PCB Substrates manufactured?

The manufacturing process of Embedded Cavity PCB Substrates involves intricate techniques and quality control measures. It typically includes motherboard manufacturing and substrate manufacturing, where materials are carefully selected, and advanced processes are employed to create the embedded cavities and ensure optimal performance.

How are Embedded Cavity PCB Substrates manufactured?

The manufacturing process for Embedded Cavity PCB Substrates involves several steps, including motherboard fabrication and substrate manufacturing. Motherboard production integrates Embedded Cavity PCB Substrates seamlessly, while substrate manufacturing employs advanced techniques and quality control measures to ensure optimal performance.

How can I obtain quotes for Embedded Cavity PCB Substrates?

Obtaining quotes for Embedded Cavity PCB Substrates involves reaching out to manufacturers directly. Provide detailed specifications and requirements to receive accurate quotes tailored to your project needs.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier