FCBGA Packaging Supplier. and FCBGA Package Substrate Manufacturing. To use the Msap and Sap technology. we offer the FC BGA Packaing and substrate service. High frequency and high speed materials are used to manufacture the packaging substrates from 2layer to 18 layers. In modern electronic manufacturing, FCBGA Packaging (ball grid array packaging) plays a vital role. This packaging method has become the first choice for many high-performance electronic devices because it has unique characteristics that make it shine in different application fields. Let us have an in-depth understanding of the importance, characteristics and applications of FCBGA Packaging.

First of all, the importance of FCBGA Packaging cannot be underestimated. In today’s digital age, we are increasingly demanding electronic devices that require higher performance, smaller size and greater reliability. FCBGA Packaging came into being because it meets these needs. Its high-density interconnect structure makes it possible to implement more functions in a limited space, which is crucial for devices pursuing miniaturization.

This article will delve into the core structure and working principles of FCBGA Packaging so that readers can better understand the internal mechanism of this packaging method. We’ll explain its unique features, including high interconnect density, excellent thermal dissipation, and signal integrity, so readers can see why it’s highly regarded.

In addition, we will explore the wide range of application areas of FCBGA Packaging. Whether in high-performance computing, communication equipment or data centers, FCBGA Packaging plays a key role. This article will provide practical application cases to show how it drives technological innovation in different fields.

In the remainder of this article, we will take an in-depth look at FCBGA Packaging’s manufacturing process, quality control measures, and future development prospects. This will help readers gain a more comprehensive understanding of the importance and potential of this packaging approach in electronics manufacturing.

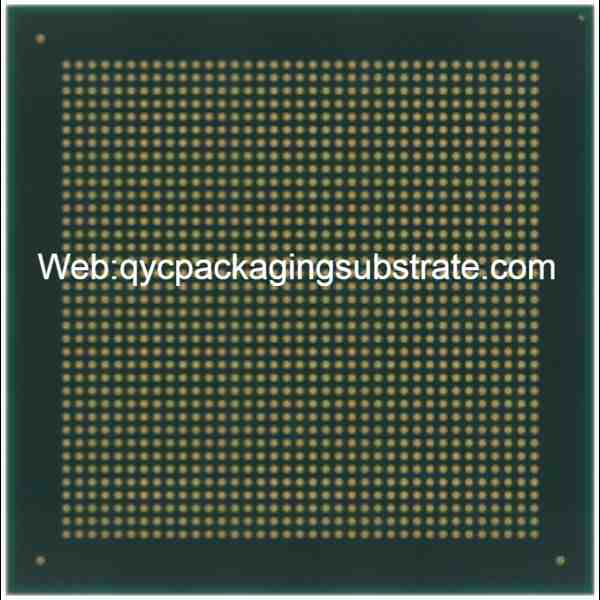

FCBGA Packaging

What makes FCBGA Packaging unique?

FCBGA Packaging (ball grid array packaging) is unique in the field of electronic packaging and has a series of significant advantages that make it highly respected in modern electronics manufacturing. The following are its significant advantages over other packaging methods:

First, FCBGA Packaging stands out for its high-density interconnects. This packaging method uses a ball grid array, allowing more connection points, allowing for higher integration. Compared with traditional packaging methods, FCBGA Packaging can accommodate more circuit components within the same physical size, which is crucial for the miniaturization and high integration of modern electronic devices.

Secondly, FCBGA Packaging performs well in terms of heat dissipation performance. As the performance of electronic devices continues to improve, the heat generated by processors and other chips has also increased significantly. The design of FCBGA Packaging takes heat conduction and dispersion into consideration to ensure that the equipment can still maintain stable operation under high load. This is particularly important in data centers, high-performance computing and communications equipment, as it ensures equipment reliability and performance.

Finally, FCBGA Packaging has excellent performance in maintaining signal integrity. Its design focuses on high-frequency signal transmission, ensuring high-quality signal transmission by reducing signal delay and reducing signal distortion. This is critical for high-speed data transmission, communications and high-performance computing as it helps reduce signal loss and noise, ensuring accurate transmission of data.

In summary, FCBGA Packaging stands out and provides a solid foundation for the performance and reliability of electronic devices through its high-density interconnection, excellent thermal dissipation and signal integrity. The unique features of this packaging method make it the first choice for many applications, and it also promotes the continuous evolution of electronic manufacturing.

FCBGA Packaging manufacturing process

In the manufacturing process of FCBGA Packaging, ensuring product quality is crucial. Quality control measures and testing procedures are key factors to ensure each FCBGA package meets specifications.

Lamination process: In the manufacturing of FCBGA Packaging, lamination is a critical step. In this process, multiple layers of substrate are bonded together through high temperatures and pressures to form a strong structure. Precise control of temperature and pressure is key to ensuring lamination quality. Any deviation in temperature or pressure can cause structural instability, affecting performance.

Solder Ball Attachment: Solder ball attachment is a critical step in connecting the chip to the packaging substrate. Each solder ball must be evenly coated with solder paste, and then soldered through precise temperature and time control. Quality control covers solder ball uniformity, adhesion, and complete soldering. Any poor soldering can cause electrical connection issues.

Testing procedures: After FCBGA Packaging is completed, each package needs to undergo strict testing procedures. These tests cover electrical performance, signal integrity, thermal performance and more. Only products that pass all tests are considered qualified. These testing procedures ensure the reliability and performance of each FCBGA Packaging.

FCBGA Packaging

Ensure FCBGA Packaging quality

In the field of electronics manufacturing, ensuring product quality is crucial. FCBGA Packaging (ball grid array packaging) is no exception, and its critical quality requirements are crucial. Here, we emphasize the importance of ensuring the quality of FCBGA Packaging and the quality control measures and testing procedures adopted.

First and foremost, quality plays a pivotal role in ensuring the reliability and performance of FCBGA (Flip Chip Ball Grid Array) Packaging. Any manufacturing defects or quality issues could potentially result in the failure of electronic devices, an outcome that is unacceptable in applications such as high-performance computing, communications, and data centers. As a result, the manufacturer implements a comprehensive array of quality control measures, ranging from the careful selection and inspection of raw materials to continuous monitoring throughout the manufacturing process, all aimed at ensuring that each FCBGA Package adheres to the specified requirements.

Furthermore, testing procedures constitute a crucial component of quality assurance. During the manufacturing process of FCBGA Packaging, the product undergoes various stages, including lamination and solder ball connection, among others. Following each step of production, rigorous testing procedures are carried out to confirm compliance with design specifications. These tests encompass electrical testing, thermal performance assessments, signal integrity evaluations, and more, all designed to validate the product’s quality and performance.

The rigor of quality control and testing procedures ensures FCBGA Packaging’s reliability in a variety of applications. Users can trust these FCBGA Packages in high-performance computers, communications equipment and data centers. Quality assurance measures not only ensure product reliability but also help reduce equipment maintenance and downtime, thereby increasing production efficiency.

In summary, quality control and testing procedures are an integral part of FCBGA Packaging manufacturing. They ensure product reliability and performance, making FCBGA Packaging the first choice for numerous applications.

In conclusion

In summary, FCBGA Packaging (ball grid array packaging) is of outstanding importance in the field of electronic manufacturing. Its key features include high-density interconnection, excellent thermal dissipation and signal integrity, making it the first choice for a variety of high-performance electronic devices. Through this article, we have a detailed understanding of the characteristics and wide application of FCBGA Packaging.

First, FCBGA Packaging’s high-density interconnect structure allows more circuits and components to be highly integrated in a smaller space, which has great potential in emerging technology fields such as 5G communications, artificial intelligence, and high-performance computing. In these fields, highly integrated electronic equipment is the engine that drives technological progress, and FCBGA Packaging is the key to achieving this goal.

Furthermore, its exceptional heat dissipation capabilities have garnered significant popularity in high-power electronic equipment, particularly in the domains of 5G communications and high-performance computing. As data transmission speeds surge and processor performance scales up, managing heat effectively becomes an increasingly pressing challenge. FCBGA Packaging ensures that equipment remains stable even under heavy workloads by efficiently conducting and dissipating heat, a crucial facet for advancing future technological developments.

In addition, FCBGA Packaging excels in the realm of high-frequency signal transmission, playing a pivotal role in maintaining signal integrity, a paramount consideration for 5G communications and other high-speed data transmission applications. The precise transmission of signals is indispensable for realizing emerging technologies and keeping pace with market trends, and FCBGA Packaging presents a reliable solution for this demand.

Within the constantly evolving landscape of electronics manufacturing, FCBGA Packaging will persist in its pivotal role, fostering the advancement of technology, innovation, and the achievement of peak performance. It will continuously adapt to new challenges and opportunities, contributing to the prosperity and innovation of the electronics manufacturing industry. The future of FCBGA Packaging is promising, poised to redefine how we engage with technology, whether in the realms of communication, entertainment, or work, and it will continue to shape the trajectory of future electronic devices.

FAQs

What is FCBGA Packaging?

FCBGA stands for Flip Chip Ball Grid Array and is a high-performance packaging technology used to connect integrated circuits to printed circuit boards (PCBs) or other substrates. It features a spherical array of solder balls that are electrically connected by flipping the chip over.

What are the advantages of FCBGA Packaging compared to other packaging?

FCBGA Packaging features high-density interconnects, excellent thermal performance and signal integrity. This makes it excellent in high-performance applications such as high-performance computing, communications and data centers.

What is the manufacturing process of FCBGA Packaging?

Manufacturing FCBGA Packaging includes steps such as lamination, solder ball connection and testing. The lamination process is used to create multi-layer packages, solder ball connections connect the chip to the substrate, and testing ensures the product meets specifications.

In what fields is FCBGA Packaging used?

FCBGA Packaging is widely used in high-performance computing, communication equipment, data centers, artificial intelligence, 5G communications and other fields requiring high performance and reliability.

How does FCBGA Packaging ensure quality and reliability?

FCBGA Packaging’s quality control includes strict manufacturing processes, reliability testing and quality control measures to ensure that products meet specifications and can operate reliably in different environments.

What are the future prospects of FCBGA Packaging?

FCBGA Packaging plays a key role in emerging technologies and market trends, such as 5G communications, artificial intelligence and high-performance computing. It will continue to grow in electronics manufacturing to meet ever-increasing performance and reliability demands.

What is the difference between FCBGA Packaging and BGA Packaging?

The difference between FCBGA Packaging and traditional BGA (Ball Grid Array) packaging is that the chip under the solder ball uses flip chip technology, making it more suitable for high-density interconnection and high-performance applications.

Is FCBGA Packaging suitable for small electronic devices?

Yes, FCBGA Packaging is suitable for devices of all sizes, including small electronic devices, due to its high integration and excellent heat dissipation performance.

How is FCBGA Packaging used in 5G communications?

FCBGA Packaging plays an important role in 5G communication equipment to support high-speed data transmission and signal processing to ensure the performance and reliability of communication equipment.

How to choose a suitable FCBGA Packaging supplier?

When selecting an FCBGA Packaging supplier, you should consider its manufacturing experience, quality control measures, and technical support. Working with reliable suppliers is key to ensuring product quality.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier