Flex-Rigid BGA Substrate Vender. We have made the Rigid-Flex BGA substrates. the BGA package substrate use the BT base and flex(PI) base.Advanced packaging substrate production process.

Packaging substrates, as core components of electronic devices, play a key role in protecting and supporting electronic components. In this complex and critical area, the introduction of Stiffener Rings marks an innovative technology that breathes new life into the performance and reliability of packaging substrates. This article will deeply analyze the importance of Stiffener Ring Substrate Packaging and explore why Stiffener Rings are widely used in the design of packaging substrates.

Stiffener Rings, as a structural reinforcement element, are more than just an add-on to the packaging substrate. They undertake multiple tasks such as maintaining substrate structural stability, optimizing thermal management, and improving the mechanical strength of electronic components. This all-round functionality makes Stiffener Ring Substrate Packaging increasingly important in the modern electronics industry.

In the complex network of packaging substrate design, why should Stiffener Rings be introduced? This is not just a technical issue, but a strategic choice. Stiffener Rings not only provide mechanical support, but also have unique advantages in thermal management and electronic component layout. Its application is not only a technological innovation, but also a firm pursuit of excellent performance and sustainable development in the electronics field.

By deeply analyzing the importance of Stiffener Ring Substrate Packaging and why it is the first choice for packaging substrate design, we can better understand how this technology can drive the entire electronics industry towards a more efficient and reliable future. In the following chapters, we will delve into the multiple advantages of Stiffener Rings in packaging substrates and their actual value in different application fields.

The function of Stiffener Ring

Stiffener Rings, as key elements in packaging substrates, play multiple important roles. Their basic concepts and key roles in the packaging process provide the basis for us to understand their value.

Stiffener Rings are rings of stiff material added around a package substrate that are designed to enhance the overall structural and mechanical stability of the substrate. These rings are typically made of strong materials, such as FR-4 fiberglass reinforced panels, which are rigid enough to effectively support surrounding electronic components and withstand the challenges of the external environment.

During the packaging process, Stiffener Rings play a vital role, affecting the performance and stability of the entire electronic device. First, they provide additional mechanical support that helps prevent the substrate from bending or twisting during use, ensuring the safety and reliability of electronic assemblies.

Secondly, Stiffener Rings play a key role in optimizing thermal management. By providing additional heat dissipation paths, they help disperse and cool the heat generated in electronic devices, ensuring that systems maintain stable operation under high loads. This is critical to avoid overheating of electronic components and improve device performance.

In addition, Stiffener Rings improve the layout of electronic components and provide a more stable foundation for components. By creating a strong structure around the substrate, they enable designers to arrange and layout electronic components more efficiently, improving overall system integration and performance.

To summarize, Stiffener Rings not only provide mechanical support but also play a vital role in thermal management and electronic component layout. They are added not only to increase hardness, but also to ensure the reliability and high performance of electronic devices in complex environments.

Advantages of Stiffener Ring in packaging substrates

The design of packaging substrates is a vital part of electronic equipment, and Stiffener Rings, as key components, are not only structural elements, but also play an active role in many aspects, further promoting the performance and reliability of packaging substrates .

Strengthening Structural Integrity

Stiffener Rings are carefully designed and one of their main tasks is to enhance the overall structure of the packaging substrate. By introducing structural supports at strategic locations, they effectively enhance the base plate’s resistance to bending and flexing, thereby improving mechanical stability.

Enhancing Mechanical Stability

The structural design of Stiffener Rings helps disperse external pressure and impact, mitigating the negative impact of mechanical stress on the substrate. This feature is particularly important in electronic equipment, especially to protect internal components from damage when exposed to external shock and vibration.

Contributing to Heat Dissipation

Stiffener Rings play a key role in thermal management during the packaging process. Its material selection and design help improve the thermal conductivity of the substrate, effectively dispersing and conducting the generated heat, reducing the risk of overheating of electronic components.

Temperature Distribution Optimization

The application of Stiffener Rings results in a more even temperature distribution, preventing the formation of hot spots. Not only does this help improve overall performance, it also extends the life of electronic equipment and reduces the frequency of repairs and replacements.

Influencing Component Arrangement

The introduction of Stiffener Rings makes the arrangement of electronic components more orderly. By providing additional support and positioning, they effectively prevent component movement and misalignment, ensuring circuit stability and reliability.

Enhancing Circuit Layout Efficiency

The use of Stiffener Rings enables more efficient layout on the circuit board. By ensuring safe placement of components, designers have more freedom to optimize and increase the efficiency of circuit layout while ensuring the accuracy and reliability of signal transmission.

The advantages in these aspects are not only the reason why Stiffener Rings are indispensable in packaging substrates, but also a key factor in promoting innovation and sustainable development in the electronics industry. In the future, this comprehensive performance advantage will continue to lead the evolution of packaging substrate technology.

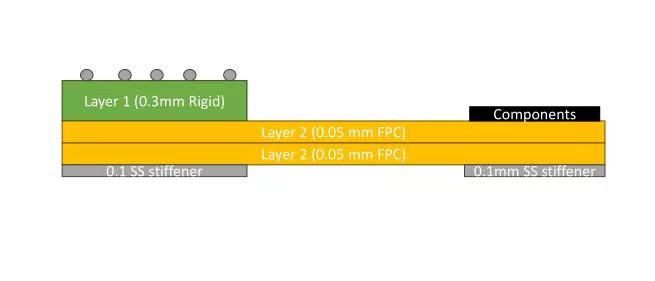

Flex-Rigid BGA Substrate

Application of Stiffener Ring in different application fields

In electronic product manufacturing, Stiffener Rings play a key role. Taking smartphones as an example, Stiffener Rings are widely used in the packaging of motherboards and other key components. By providing additional mechanical support, Stiffener Rings effectively strengthen the overall structure and reduce the risk of motherboard bending. This structural advantage improves the overall durability of the product while protecting the internal electronic components from external impacts.

The introduction of Stiffener Rings enables electronics manufacturing to better adapt to shrinking device sizes and higher performance requirements. By increasing structural strength and improving heat dissipation, Stiffener Rings help create more compact, more efficient electronic devices. This not only improves product reliability, but also enables manufacturers to launch more competitive products to meet evolving market demands.

In the field of communication technology, Stiffener Rings are widely used to encapsulate key communication equipment. For example, base station antenna packaging using Stiffener Rings is designed to cope with the challenges posed by harsh weather conditions and long-term operation. The use of Stiffener Rings ensures the stability of the package and provides additional mechanical support to resist adverse effects of the external environment on the device.

The application of Stiffener Rings in communication equipment not only improves the structural stability of the equipment, but also optimizes its overall performance. By improving heat dissipation and the layout of electronic components, Stiffener Rings help keep equipment running efficiently, ensuring communications equipment can provide stable, reliable service under a variety of conditions. This is critical to maintaining the high performance of communications networks, especially amid growing connectivity demands.

Through these practical cases and application examples, we can clearly see the importance of Stiffener Rings in the fields of electronic product manufacturing and communication technology, and how they meet the needs of the industry and improve product reliability and performance. This is not only a key technology choice for manufacturers, but also injects new vitality into the development of the entire electronics industry.

Why choose Stiffener Rings?

When choosing packaging technology, Stiffener Rings have become a much-discussed option due to their unique characteristics and advantages. By comparing it to other packaging technologies, we can get a clearer picture of why Stiffener Rings are considered ideal in many scenarios.

Rigid-Flex technology offers a combination of flexibility and rigidity, but may have some limitations in terms of mechanical stability. In contrast, Stiffener Rings improve the overall stability of the substrate by adding rigidity, especially in more demanding environments.

Traditional PCB technology may lack adequate mechanical support in some cases, especially in large electronic products. Stiffener Rings solve this potential problem by providing additional support to the substrate.

With Thermal Via Technology

Thermal Via technology is powerful in terms of thermal management, but may be slightly lacking in mechanical stability. Stiffener Rings effectively improve thermal management performance while maintaining mechanical stability.

Improved mechanical stability

Stiffener Rings provide superior mechanical stability by increasing the rigidity of the substrate, especially in large electronic devices or in extreme environments.

Thermal Management Advantages

In high-temperature environments, Stiffener Rings play a unique role in optimizing thermal management and ensuring that electronic components operate within the optimal temperature range.

Improvements in electronic layout

By influencing how electronic components are arranged, Stiffener Rings play a key role in circuit layout, improving the performance and efficiency of electronic products.

Environmental adaptability

Stiffener Rings are designed to adapt to a variety of environments, thereby enhancing the durability and reliability of the substrate.

To sum up, choosing Stiffener Rings is not just a technical choice, but also a strategic decision that comprehensively considers many factors such as mechanical stability, thermal management, and electronic layout.

Through these comparisons, it is not difficult to understand why Stiffener Rings occupy a core position in packaging substrate technology and become the first choice of many engineers and designers. In the face of diverse demands and the ever-evolving electronics field, choosing Stiffener Rings is a powerful step in promoting innovation and sustainable practices.

The future outlook of Stiffener ring substrate packaging

In the continuous evolution of packaging substrate technology, Stiffener Rings will continue to play a key role and are expected to usher in more innovations. The direction of future development is mainly focused on the following key areas:

Material innovation and lightweighting: As the demand for lightweight electronic equipment increases, future Stiffener Rings may use more advanced lightweight materials to ensure mechanical stability while reducing the overall weight, providing more possibilities for mobile devices and other fields. sex.

Intelligence and sensing technology: With the rapid development of the Internet of Things and intelligent technology, future Stiffener Rings may integrate more sensing technologies to achieve real-time response to environmental changes. This will help improve the adaptability and stability of the device.

Sustainability and environmental protection: With the increasing global focus on sustainability, future Stiffener Rings are expected to adopt more environmentally friendly materials and manufacturing processes to reduce the impact on the environment and comply with the trend of green packaging.

The continuous innovation of Stiffener Ring technology will have a profound impact on packaging substrate technology and provide strong support for the advancement of the electronic field.

Improve overall system performance: By providing stable mechanical support and thermal management, Stiffener Rings help improve overall electronic system performance. This is critical to the trend toward higher performance and smaller size in modern electronic devices.

Promote the application of advanced packaging technology: The innovation of Stiffener Rings will promote the continuous development of packaging technology and stimulate the application of more advanced packaging technologies, such as 3D packaging and ultra-thin packaging, thereby promoting innovation in the entire electronic packaging industry.

Adapt to diverse needs: With the diversification of market demands, the innovation of Stiffener Rings will make the packaging substrate more flexible and able to adapt to various application scenarios, including the continuous development of medical, automotive, communications and other fields.

In the future, Stiffener Ring technology is expected to create new possibilities in the electronic field and inject lasting power into the continuous evolution and innovation of the industry. Its key position will be further highlighted with the development of technology, becoming a key engine to promote the advancement of packaging substrate technology.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier