What is Microtrace LED PCB?

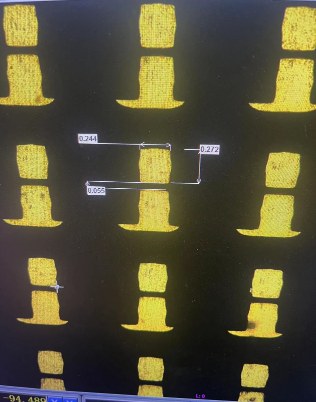

Microtrace LED PCB Manufacturer. Microtrace and microgap LED PCBs, the best smallest pads to pads gap are 30um, 40um, 50um, 60um, we also can do the gap with 20um. but the price is not good.

Microtrace LED PCB is a special type of printed circuit board (PCB) produced by Microtrace LED PCB manufacturers and is specifically used to support and connect the basic materials of LED (Light Emitting Diode) components. Today, with the rapid development of LED technology, Microtrace LED PCB, as an important part of the LED lighting industry, plays a key role.

Microtrace LED PCBs offer a unique set of features that make them the first choice in LED applications. First of all, Microtrace LED PCB uses advanced materials and processes to ensure it has excellent thermal conductivity and electrical performance. This characteristic is very important because LED components generate high heat when working, and good thermal conductivity can effectively conduct heat away, maintain the stable operating temperature of LED components, and extend their life.

Secondly, Microtrace LED PCB has good mechanical strength and stability and can withstand vibration and impact under various environmental conditions, ensuring the reliability and durability of the LED system. This is particularly important for the application of LED lighting in outdoor, automotive lighting and other fields.

In addition, Microtrace LED PCB also has flexible design and customization capabilities. It can be customized according to customer needs and application scenarios to meet different size, shape and function requirements. Whether in LED lighting, automobiles, electronic products or other fields, Microtrace LED PCB can provide the best solutions.

In general, Microtrace LED PCB is a printed circuit board with excellent performance and diversified applications, which provides important support for the development and application of LED technology. As a product of Microtrace LED PCB manufacturer, it represents the latest technology and innovation in the LED lighting industry, providing customers with high-quality LED solutions and assisting the continuous advancement and application expansion of LED technology.

Microtrace LED PCB design Reference Guide.

Microtrace LED PCB manufacturer is well-known in the industry for its excellent technology and professional team, and its design services are even more impressive. The Microtrace LED PCB Design Reference Guide aims to provide customers with the best LED PCB design solutions and provides an in-depth discussion of how to achieve high-performance LED PCBs.

First of all, the design team of Microtrace LED PCB manufacturer has rich experience and professional knowledge, and can fully understand customer needs and provide customized solutions for different application scenarios. Whether in lighting, automotive, electronics or other fields, Microtrace LED PCB design team is able to design high-performance LED PCBs that meet customer needs.

Secondly, the Microtrace LED PCB Design Reference Guide details the key elements and best practices of LED PCB design. From circuit layout to thermal design, from material selection to protective measures, the Microtrace LED PCB Design Reference Guide provides customers with comprehensive design guidance to help them achieve optimal performance and reliability of their LED PCBs.

In addition, Microtrace LED PCB manufacturers also actively introduce the latest design tools and technologies to continuously improve design efficiency and quality. They work closely with customers from concept design to prototype verification to volume manufacturing to ensure that customer needs and expectations are met at every stage.

In summary, the Microtrace LED PCB Design Reference Guide provides customers with a one-stop LED PCB design solution designed to help them achieve the best performance and application results of LED technology. Whether you are a novice or an experienced engineer, you can get valuable guidance and inspiration to achieve success and excellence in LED PCB design.

White core Microtrace LED PCB

What material is used in Microtrace LED PCB?

Microtrace LED PCB manufacturers use a range of advanced materials in their products to ensure that their PCBs have excellent performance characteristics such as good thermal conductivity, electrical performance and mechanical strength. With the rapid development of LED technology and the continuous improvement of application requirements, it is crucial to select appropriate materials that can effectively meet the heat dissipation and stability requirements of LED PCBs.

First of all, one of the materials commonly used by Microtrace LED PCB manufacturers is FR-4. FR-4 is a common fiberglass reinforced epoxy resin material with good mechanical strength and heat resistance. Its high-strength glass fiber reinforced layer gives the PCB excellent stability under mechanical vibration and stress, ensuring long-term stable operation of LED lamps under various environmental conditions.

In addition, Microtrace LED PCB manufacturers also use metal substrates as one of the PCB materials. Metal substrate is a PCB material with a metal base, usually aluminum substrate and copper substrate. These metal substrates have good thermal conductivity and can effectively dissipate heat, ensuring that LED lamps can maintain a stable temperature when operating at high power. In addition, metal substrates also have excellent electrical properties and mechanical strength, making them suitable for various LED application scenarios.

In addition to FR-4 and metal substrates, Microtrace LED PCB manufacturers can also choose other high-performance materials according to customer needs, such as ceramic substrates, polyimide substrates, etc. These materials have excellent thermal conductivity, electrical properties and mechanical strength, and can meet the strict requirements of LED technology for PCB materials.

In general, Microtrace LED PCB manufacturers focus on using advanced materials and processes in material selection to ensure that their products have excellent performance and reliability. Whether in the fields of LED lighting, automotive lighting or display screens, Microtrace LED PCB can provide customers with high-quality LED PCB solutions to help the development and application of LED technology.

Black core Microtrace LED PCB

What size are Microtrace LED PCB?

LED PCB size is a key design consideration for Microtrace LED PCB manufacturers. Usually, the size of LED PCB is not fixed, but is customized and produced according to specific application requirements. Microtrace is committed to providing customers with LED PCB solutions that perfectly match their application scenarios, so they offer a wide range of size and shape options to meet a variety of needs.

In the field of LED lighting, the size of LED PCB may vary depending on the application scenario. For example, in indoor lighting, LED lamps usually require smaller and thin PCBs to be embedded into various lamp designs, such as chandeliers, downlights, etc. In the field of outdoor lighting, LED lamps may require larger PCB sizes to meet higher power requirements and more complex environmental conditions.

In addition, Microtrace LED PCB manufacturers can also provide customized sizes and designs based on customers’ specific needs. Whether it is a special shape, non-standard size or specific functional requirements, their professional team is able to provide customized solutions to ensure that the LED PCB perfectly matches the customer’s product.

Due to the continuous development of LED technology and the diversification of application scenarios, Microtrace LED PCB manufacturers continue to promote innovation in LED PCB size and design. They not only focus on the size of the LED PCB, but also on its cooperation with other components and the optimization of overall performance to ensure the best performance and stability of the LED system.

In short, Microtrace LED PCB manufacturer provides customers with a variety of LED PCB size options with its flexible customization capabilities and professional technical support. Whether it is a simple lighting application or a complex industrial project, they can provide high-quality, high-performance LED PCB solutions to help customers achieve project success.

The Manufacturer Process of Microtrace LED PCB.

Microtrace LED PCB manufacturer provides one-stop service from design to manufacturing based on its advanced production equipment and technology. Their manufacturing process is carefully designed and includes multiple links to ensure the high quality and stability of PCBs.

First, material preparation is a crucial step in the manufacturing process. Microtrace LED PCB manufacturers choose high-quality raw materials such as FR-4 and metal substrates to ensure that the PCB has good thermal conductivity and mechanical strength. They strictly control the quality of raw materials to ensure that each PCB can achieve the expected performance indicators.

Next comes the printing stage. At this stage, the circuit pattern of the PCB is printed onto the substrate. Microtrace LED PCB manufacturers use advanced printing technology to ensure the accuracy and consistency of circuit patterns. They use high-precision printing equipment that can achieve precise printing of complex circuit patterns.

Plating is another critical step in the manufacturing process. During the electroplating process, a metal layer is deposited onto the printed circuit pattern to form a conductive layer. Microtrace LED PCB manufacturers use advanced electroplating technology to ensure uniform deposition and good adhesion of the metal layer, thereby improving the conductivity and corrosion resistance of the PCB.

Soldering is a critical step in connecting electronic components to a PCB. Microtrace LED PCB manufacturers use advanced soldering technologies such as surface mount technology (SMT) and plug-in soldering technology to ensure reliable connection between electronic components and PCB. They strictly control the welding temperature and time to prevent component damage or poor welding.

Finally comes the assembly stage. At this stage, the electronic components on the PCB are installed into the device or system to which they are applied. Microtrace LED PCB manufacturer has a professional assembly team that can provide customized assembly services according to customer needs. They strictly implement the assembly process to ensure that each component is installed correctly, thereby ensuring the stability and reliability of the entire system.

In general, Microtrace LED PCB manufacturers ensure the high quality and stability of PCBs through their advanced production equipment and technology, as well as strict manufacturing processes. They constantly pursue technological innovation and quality improvement, and are committed to providing customers with the highest quality LED PCB solutions.

The Application area of Microtrace LED PCB.

LED PCB is widely used in various fields, including lighting, automobiles, electronic products, etc. Microtrace LED PCB manufacturer’s products are widely used in LED lighting, automotive lighting, display screens and other fields, providing customers with high-quality LED solutions.

LED lighting is one of the most common applications of LED PCBs. The application of LED lamps in the lighting industry has become a trend, and its characteristics of high efficiency, long life and energy saving have attracted widespread attention. LED PCBs produced by Microtrace LED PCB manufacturers are widely used in various scenarios such as indoor lighting, outdoor lighting, landscape lighting, etc., providing users with bright and energy-saving lighting solutions.

With the continuous development of the automotive industry, LED technology is increasingly used in automotive lighting. LED lamps have the advantages of high brightness, low energy consumption, and long life, making them the first choice for automobile headlights, taillights, turn signals, etc. Microtrace LED PCB manufacturer’s products are used in automobile lighting, providing automobile manufacturers with high-quality lighting solutions and improving the safety and aesthetics of automobiles.

As a new display technology, LED display screen has been widely used in advertising, information release, stage performances and other fields indoors and outdoors. LED PCB is the core component of LED display screen. Its stability and reliability directly affect the display effect and service life. Microtrace LED PCB manufacturer’s products are widely used in LED displays, providing customers with high-definition and high-brightness display effects, meeting the needs for display equipment in different occasions.

In short, the LED PCBs produced by Microtrace LED PCB manufacturers are widely used in lighting, automotive lighting, display screens and other fields, providing customers with high-quality, high-performance LED solutions and promoting the development and development of LED technology in various fields. application.

What are the advantages of Microtrace LED PCB?

Microtrace LED PCB manufacturer is committed to providing customers with excellent LED PCB solutions, and its products have a series of advantages that make it a leader in the field of LED technology. The following are the advantages of Microtrace LED PCB:

Microtrace LED PCB manufacturers use high-quality materials and advanced processes to ensure that their products have excellent performance and stability. The materials they selected have good thermal conductivity, electrical properties and mechanical strength, and can meet the strict requirements of LED technology for heat dissipation and reliability. Moreover, they continue to introduce the latest production technology and equipment to maintain their leading position in the industry.

Microtrace LED PCB manufacturer has a professional design team that can provide customized PCB design services according to customer needs. Regardless of size, shape or function, they are able to tailor the most suitable LED PCB solutions for customers. By working closely with their clients, they ensure that each project meets their expectations and achieves optimal performance.

Microtrace LED PCB manufacturers are able to achieve a high degree of integration and density of LED circuits, minimizing the size and weight of the circuit board. Their design team not only focuses on the functionality of the circuit, but also on the layout and wiring of the circuit board to ensure the stability and reliability of the circuit. This high degree of integration and density enables LED PCB to be used in various compact devices and application scenarios, such as LED lamps, automotive lighting, etc.

Microtrace LED PCB manufacturer’s products have excellent stability and reliability, ensuring long-term stable operation of LED circuits. They strictly control every aspect of the production process, from material selection to production technology, to ensure stable product quality and performance. This stability and reliability enable Microtrace LED PCB to perform well under various harsh environmental conditions, such as high temperature, high humidity, etc.

Compared with traditional LED PCB manufacturers, Microtrace LED PCB manufacturers are able to provide more cost-effective solutions. They reduce the manufacturing cost of products by optimizing production processes and improving production efficiency, thereby saving costs for customers. In addition, they also provide customized design services and can flexibly adjust product specifications and configurations according to customer needs to maximize customer needs and reduce customer procurement costs.

To sum up, Microtrace LED PCB manufacturer has become a leader in the LED technology field with its high-quality products, customized design services and cost-effective advantages. They continue to innovate and progress, and are committed to providing customers with the best LED PCB solutions and promoting the development and application of LED technology.

FAQ

What advantages does Microtrace LED PCB manufacturer have over other suppliers?

Microtrace LED PCB manufacturer has many years of PCB manufacturing experience and rich LED technology knowledge. They focus on the design and manufacturing of LED PCBs, and through continuous technological innovation and quality control, ensure that the performance and stability of their products reach industry-leading levels. In addition, Microtrace LED PCB manufacturers provide customized services and can provide personalized solutions according to customer needs to meet the needs of different application scenarios.

What is the design process of LED PCB?

The design process of LED PCB usually includes the following steps: First, demand analysis and solution formulation are carried out according to customer needs and application scenarios; then, the design team develops PCB layout and circuit connection plans according to needs; then, schematic design and Circuit simulation verification ensures the accuracy and stability of the design; finally, PCB wiring and layout design is performed through PCB design software to generate the final PCB design file.

How long is the manufacturing cycle of LED PCB?

The manufacturing cycle of LED PCB usually depends on the specific design requirements and production process. Generally, it takes about 2 to 4 weeks from design to completion of manufacturing. However, for urgent orders or special requirements, Microtrace LED PCB manufacturers can also provide expedited production services to shorten the manufacturing cycle.

How is the quality control of LED PCB carried out?

Microtrace LED PCB manufacturers strictly follow the ISO quality management system to ensure product quality and stability. They use advanced testing equipment and technology to conduct strict quality inspection and control on every process. Every link from raw materials to finished products undergoes strict inspection and testing to ensure that the quality of the products meets customer requirements and standards.

What are the application scopes of LED PCB?

LED PCB is widely used in various fields, including LED lighting, automotive lighting, electronic products, communication equipment, etc. Microtrace LED PCB manufacturer’s products are widely used in LED lamps, automotive lights, displays and other fields, providing customers with high-performance and reliable LED solutions.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier