We are a professional Substrate in packaging, we mainly produce ultra-small bump pitch substrate, ultra-small trace and spacing packaging substrate and PCBs.

Packaging substrates, as an integral part of modern electronic equipment, are key elements that connect, support and protect electronic components. In this high-tech era, we usually talk about the performance, speed and functionality of electronic products, but few people pay attention to the silent heroes working inside these devices – the packaging substrate.

The packaging substrate is a plate-like object that carries and connects electronic components. It enables various components to work together by providing electrical connections and physical support. This seemingly simple board plays an important role in the technological arena, serving as a medium for information exchange and collaboration between the various components within an electronic device.

Packaging substrates usually adopt multi-layer designs, providing a tight and effective working environment for electronic components through precise wiring and complex hierarchical structures. Different types of packaging substrates, such as silicon-based packaging and organic substrate packaging, have their own unique advantages and application scenarios.

However, when discussing packaging substrates, we often overlook a crucial aspect – the base material used in the packaging substrate. This brings us to the core topic of this article: “Substrates in Packaging”. The choice of substrate directly affects the performance, stability and adaptability of the packaging substrate in specific applications.

This article will delve deeper into different types of substrates, focusing specifically on silicon-based packaging and organic substrate packaging, to explore their unique contributions in electronic packaging. We’ll unpack the role of substrates in signal transmission, thermal management, and other critical functions, revealing their indispensability in modern electronic devices.

By in-depth study of the properties and characteristics of substrates, we can better understand the operating mechanism of packaging substrates and provide a more solid foundation for future electronic technology development. This article will lead you into the wonderful world of packaging substrates, explore the subtle applications of substrates, and bring readers a new technological perspective.

Substrate in packaging

What is a substrate in packaging?

Substrate in Packaging refers to the key element in the electronic packaging process, that is, the basic material that supports and connects electronic components. This can be of a variety of materials, including silicone-based, organic-based, etc., the choice of which depends on the requirements and performance criteria of the application. Substrates are the backbone of electronic packaging, providing structure and support for various components.

In electronic packaging, substrates play a vital role. First, it is the foundation of the circuit board, providing support for various electronic components. Different types of substrates have different properties in terms of electrical performance, thermal management, and mechanical strength, so selection in a specific application is critical.

Signal transmission and electrical performance

Substrate serves as a signal transmission medium in the circuit board, affecting the communication effect between electronic components.

The electrical properties of different substrates are critical to maintaining signal stability, especially in high-frequency applications.

Thermal management and cooling performance

The heat generated by high-performance electronic devices needs to be managed and dissipated efficiently, and substrates play a key role in this process.

Choosing the right substrate can ensure that electronic components maintain a stable operating temperature under high loads.

Mechanical strength and structural support

The mechanical properties of the substrate are critical to supporting and protecting electronic components, especially applications in harsh environments.

Structural stability and strength are essential contributions of substrates in packaging.

In general, Substrate in Packaging is an indispensable part of electronic packaging and directly affects the performance, reliability and stability of the equipment. Proper selection and optimization of the properties of substrates are critical to advancing the electronics field.

Type of packaging substrate

In the field of electronic packaging, there are various types of packaging substrates, among which silicon-based packaging substrates and organic substrate packaging substrates are two areas that have attracted much attention.

Silicon based packaging substrate

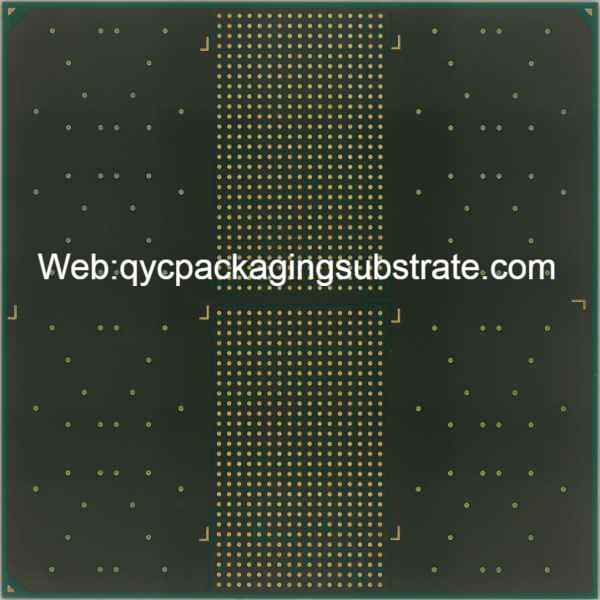

The silicon-based packaging substrate is constructed of silicon material and has excellent mechanical strength and thermal conductivity. Its multi-layer structure ensures that highly integrated circuits can be implemented in small-size packages. The characteristics of silicon-based packaging substrates make them excellent in high-density, high-performance applications.

Silicon-based packaging substrates are widely used in the packaging of electronic components such as high-performance processors and graphics processing units (GPUs). Its excellent heat dissipation performance makes it an ideal packaging choice for chips that process large amounts of data and high-load operations. In fields such as artificial intelligence and cloud computing, silicon-based packaging substrates play a key role in ensuring device reliability and performance.

Organic substrate packaging substrate

Organic substrate packaging substrates are constructed of organic materials and have the advantages of being lightweight, flexible, and lower cost than silicon-based packaging substrates. Its flexibility and plasticity make it suitable for packaging needs of various complex shapes and sizes. In addition, organic substrates have unique advantages for high-frequency signal transmission.

Organic substrate packaging substrates have shown new application prospects in modern electronic packaging, especially in the fields of flexible electronics and wearable devices. Its lightness and flexibility make it ideal for bendable and customizable electronics. From smart clothing to portable medical devices, organic packaging substrates are driving innovation in electronic packaging.

In this evolving field, silicon-based and organic-based packaging substrates each drive the progress of the electronics industry with their unique advantages, providing more intelligent and flexible solutions for our lives and work.

The key role of substrates in electronic product packaging

In the design and manufacturing of modern electronics, packaging substrate selection is critical to overall performance. Here are two key roles that substrates play in electronic product packaging:

Electrical Characteristics in Circuits

As the supporting structure of electronic components, packaging substrate directly affects signal transmission and circuit performance. Different base materials have a significant impact on the transmission speed and impedance matching of electronic signals. Silicon-based packaging substrates are often used in high-frequency circuits because of their excellent conductivity and low dielectric loss, which provide higher signal transmission speed and lower signal distortion.

In modern communications and computing devices, data transmission speed and stability are critical. Selecting the appropriate substrate can effectively reduce signal attenuation and crosstalk, ensuring the stability and reliability of electronic products in high-speed communication and computing environments.

Thermal management and cooling performance

High-performance electronic devices generate large amounts of heat during operation, and packaging substrates play a key role in this. Organic substrate packaging substrates usually have good heat dissipation properties, which help to effectively conduct heat away from electronic components and maintain a stable operating temperature of the equipment.

High-performance computers, graphics processing units (GPUs), and other big data processing equipment often use multi-layer composite substrates to improve heat dissipation. This design ensures the stability of the equipment under long-term high-load operation and prolongs the life of electronic components.

By comprehensively considering signal transmission and thermal management requirements, selecting the appropriate packaging substrate base material is critical to the performance, stability, and reliability of electronic products. This comprehensive consideration reflects the central role of the substrate in packaging to the entire electronic system. In the future, as technology continues to evolve, we are expected to see more innovative substrate solutions to meet the ever-increasing performance demands of electronic products.

Future trends in packaging substrates

In the evolution of packaging technology, the development of substrates has become a key focus. In the future, we foresee that the following trends will shape the technology direction of packaging substrates:

The rise of high-performance materials: As electronic devices continue to pursue performance, substrates will pay more attention to the characteristics of high frequency, low loss and high signal integrity. The emergence of new high-performance materials will promote innovation in electronic product packaging.

Flexible and bendable substrates: In order to adapt to the increasingly diverse electronic product designs, substrates will develop in a more flexible and bendable direction. This trend will promote the rise of flexible electronics, providing more possibilities for areas such as wearable devices and foldable screens.

Multifunctional substrate: In the future, substrates will not only be carriers to support circuits, but will also have multiple functions, such as optical transparency, dustproof and waterproof, and even energy transmission. This versatility will provide more innovative possibilities for electronic devices.

As society becomes increasingly concerned about sustainability, substrate selection will be subject to more stringent environmental standards. This development trend has a profound impact on the future of packaging technology:

Circular economy materials: Substrate manufacturing will tend to adopt recyclable and degradable materials to reduce dependence on limited resources. The concept of circular economy will promote the sustainable development of the substrate industry.

Low energy consumption production: Future substrate production will pay more attention to low energy consumption and low emissions. Adopting green production processes to reduce the burden on the environment is an important step for substrate manufacturers to embrace a sustainable future.

Environmentally friendly design: The design of packaging substrates will pay more attention to environmental protection and avoid the use of environmentally harmful substances. Substrate manufacturers will consider the possibility of recycling and degradation in product design to reduce the negative impact of waste on the environment.

Taken together, future packaging substrates will not only be a promoter of technological innovation, but will also play an important role in sustainability and environmental protection, leading the electronics field to move towards a more sustainable future.

Full text overview of packaging substrates

In the complex ecosystem of electronic packaging, packaging substrates play a key role, providing fundamental support for the performance and reliability of electronic devices. This article provides an in-depth discussion of the core component of the packaging substrate – the base material, as well as its key position and future development trends in electronic packaging.

The packaging substrate is the skeleton of electronic products and supports the operation of the circuit. Silicon-based packaging substrates are popular for their stability and reliability, while organic-based packaging substrates have a place in modern electronic devices due to their light weight and flexibility. These two substrates play a vital role in signal transmission, electrical performance, thermal management, and more. Their selection directly affects the performance, cooling effect and overall reliability of electronic products.

With the continuous development of technology, electronic products are changing with each passing day. In order to adapt to rapidly changing market demands, innovation has become the engine that drives packaging technology forward. It is not only necessary to continuously improve the performance of silicon-based packaging substrates, but also to continuously explore new possibilities in the field of organic substrate packaging substrates. In this process, sustainable practices are integral. We need to find materials and manufacturing processes that both improve performance and are environmentally friendly. Only through continued innovation and sustainable practices can packaging substrate technology continue to evolve and adapt to future challenges in the electronics field.

Overall, packaging substrates are the cornerstone of electronics, and innovation and sustainable practices are key to keeping this foundation strong. Through in-depth understanding of substrates and continuous technological innovation, we can achieve greater achievements in the field of electronic packaging and promote the development of the entire industry towards a more advanced and sustainable future.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier