Cavity Substrate PCB Manufacturer.High speed and high frequency material cavity packaging substrate manufacturing. Advanced Depth control production technology. We produce the depth and dimensions of the grooves according to your requirements.

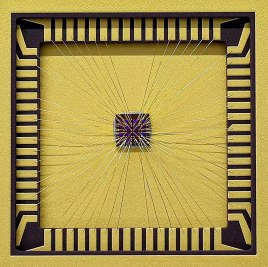

The paragraph describes the significance of Cavity Substrate PCB in contemporary electronic equipment. It highlights its pivotal role in electronic engineering, offering a sturdy foundation and dependable support for diverse electronic devices. Unlike conventional PCBs, Cavity Substrate PCBs are distinguished by their distinctive design and structure, featuring dedicated recesses tailored to house essential components like chips, sensors, and other critical electronic elements.

The existence of these dedicated cavities allows Cavity Substrate PCB to optimize space utilization and effectively embed key components inside the PCB, thereby achieving a more compact design. In contrast, traditional PCB designs can be space-constrained and unable to efficiently house large or complex components, limiting the performance and functionality of electronic devices.

The passage describes the benefits of Cavity Substrate PCBs, which optimize space utilization and enhance overall performance in electronic devices. These PCBs embed key components within specialized cavities, enabling superior thermal management and electrical performance. The cavities effectively dissipate heat, ensuring stable operating temperatures for electronic devices while also reducing electromagnetic interference and enhancing signal integrity. In summary, Cavity Substrate PCBs offer an innovative design solution that provides a robust foundation and optimized performance for various electronic devices, making them essential in modern electronic engineering.

What are the types of Cavity Substrate PCB?

This passage discusses various types of Cavity Substrate PCBs commonly used in modern electronics, highlighting their unique features and benefits.

This paragraph describes different types of cavity substrates used in electronic devices:

Organic Cavity Substrates: These substrates are crafted from flexible and cost-effective organic materials. Their flexibility enables their application in various electronic devices of diverse shapes and sizes. Given their relatively lower cost compared to other substrates, they are widely favored for numerous projects.

This paragraph describes ceramic cavity substrates, emphasizing their construction from ceramic materials, which provide excellent thermal conductivity and reliability. These substrates efficiently dissipate heat, preventing electronics from overheating, and they are highly durable, making them suitable for challenging environments.

They find extensive use in applications necessitating top-tier electronic performance, such as communication equipment and computer chips. Silicon substrates boast exceptional electrical conductivity, making them ideal for high-end electronic devices.

In summary, each type of Cavity Substrate PCB offers distinct advantages. Selecting the appropriate type for a project can enhance electronic equipment’s performance and reliability, contributing to the ongoing advancement of the electronics industry.

What are the advantages of Cavity Substrate PCB?

Cavity Substrate PCB offers multiple advantages that make it a popular choice in the design of modern electronic devices.

This paragraph highlights the superior attributes of Cavity Substrate PCBs, emphasizing their effectiveness in thermal management, electrical performance, compact design, and robust construction. These PCBs excel in dissipating heat, ensuring device stability and longevity, crucial in the context of shrinking device sizes and increasing performance demands. This passage describes the attributes of a certain type of technology or equipment. It highlights its ability to optimize signal integrity, reduce electromagnetic interference, and its suitability for high-frequency and high-speed data transmission tasks. Furthermore, it emphasizes that the design is compact and lightweight, making it perfect for situations with limited space while still maintaining flexibility.Moreover, their robust construction ensures excellent reliability and durability, capable of withstanding harsh environmental conditions, ultimately providing long-term stability and assurance for electronic equipment.

In summary, Cavity Substrate PCBs have become the preferred choice in modern electronic equipment design, offering efficient thermal management, enhanced electrical performance, a compact design, and exceptional reliability and durability. Their advantages position them prominently in various application scenarios, driving continuous progress and innovation in electronic technology.

Why choose Cavity Substrate PCB?

Cavity Substrate PCBs are gaining prominence in the current competitive electronics market, standing out for their unique advantages over traditional PCBs. Their compact design allows for more efficient space utilization and greater flexibility in electronic device configurations. This is particularly important in modern electronics, where the demand for smaller and lighter devices drives the need for refined and compact designs.

Secondly, Cavity Substrate PCBs exhibit excellent thermal management performance. Given the inevitable heat generation in electronic equipment, their unique structure and material selection allow for more effective heat dissipation, ensuring stable equipment operation. This enhanced thermal management not only extends device lifespan but also improves performance and stability, ultimately providing users with a better experience.

In conclusion, the outstanding performance of Cavity Substrate PCBs in compact design and optimized thermal management gives them a distinctive competitive edge in today’s electronics market. As technology continues to advance and market demand grows, Cavity Substrate PCBs are poised to play an increasingly significant role in future developments, solidifying their status as the top choice in electronic equipment design.

Cavity Substrate PCB

How to make Cavity Substrate PCB?

The production of Cavity Substrate PCB is a complex and precise process that comprises two crucial stages: motherboard manufacturing and substrate manufacturing.

Advanced craftsmanship is employed to seamlessly integrate it with the Cavity Substrate and various electronic components. The process begins with the selection of a suitable substrate material, often FR-4 fiberglass composite known for thermal conductivity and mechanical strength. Circuit lines and connection holes are then created through chemical or mechanical processing, with special attention given to maintaining circuit integrity for optimal reliability and performance.

Substrate manufacturing for Cavity Substrate PCB primarily centers around crafting the substrate, which houses specially designed cavities for crucial components. This involves employing precision craftsmanship, top-notch materials, and advanced technologies. The choice of substrate material is dictated by application needs, with organic materials, ceramics, and silicon being common options. The desired cavity structure is meticulously formed using techniques such as thin film deposition, electrochemical deposition, and micromachining. Rigorous control is upheld throughout the process to guarantee the utmost substrate quality and precision.

The final step involves the precise combination of the motherboard and substrate to create a complete Cavity Substrate PCB. This intricate process demands technical expertise and precision operations to guarantee the performance and reliability of the end product. Overall, the manufacturing of Cavity Substrate PCBs relies on precision workmanship and high-quality materials, achieved through meticulous motherboard and substrate manufacturing processes. This ensures seamless integration and optimized performance, providing robust support for the development of electronic devices.

What are the application fields of Cavity Substrate PCB?

The Cavity Substrate PCB (CSPCB) plays a crucial role as an essential electronic component with broad applications in diverse industries such as consumer electronics, automotive, and medical equipment. Specifically within the realm of consumer electronics, CSPCB is widely employed in devices like smartphones, tablets, laptops, and smart home products. Its compact design and efficient thermal management contribute to the creation of sleek, lightweight, high-performance devices that excel in heat dissipation. This, in turn, enhances overall product stability and reliability.

The automotive industry, experiencing a growing demand for electronic systems, relies significantly on CSPCB for integration into vehicle navigation systems, entertainment systems, and driving assistance systems. CSPCB’s role in these applications is crucial, offering efficient electrical performance and a stable operational environment. Additionally, its compact design aligns with the space constraints of automotive electronic equipment, further supporting the industry’s evolving needs.

In the field of medical equipment, CSPCB is widely used in medical diagnostic instruments, implantable medical equipment, life support systems and other products. Its excellent thermal management and electrical performance ensure the stable operation of medical equipment and comply with strict medical safety standards.

The application of CSPCB extends beyond the mentioned industries to include aerospace, industrial control, communications, and various other fields. Its high adaptability and stability make CSPCB a crucial and essential component in diverse industries, fostering innovation and technological advancements across various sectors.

Where to find Cavity Substrate PCB manufacturers?

We are a well-established manufacturer specializing in high-quality Cavity Substrate PCBs, committed to providing customized products and services to meet a wide range of customer requirements. With extensive professional experience and technical proficiency, we are leaders in the industry, utilizing advanced manufacturing technology and top-tier materials.

Our emphasis on personalized customization ensures that our products align with specific customer requirements. Stringent quality control measures are implemented, upholding the highest industry standards through thorough inspection of each product batch.

On-time delivery is a core aspect of our commitment, as we prioritize maintaining timely delivery cycles to support our customers’ project timelines. As a trusted Cavity Substrate PCB manufacturer, we guarantee outstanding product quality and exceptional service. We work closely with our customers to collaboratively shape a better future.

Several factors, such as selected materials, manufacturing process complexity, specification requirements, and order quantity, influence the pricing. Transparent pricing structures from leading manufacturers offer customers a clear understanding of the value and quality of the products.

To secure an accurate quote, it is essential to provide precise information during communication with the manufacturer. Professional customer service teams, typically associated with leading manufacturers, diligently listen to customers’ needs, offering customized solutions and competitive quotations based on specific requirements. These teams work collaboratively with customers to ensure a comprehensive understanding of their needs and to provide the most competitive prices.

As a reliable manufacturer specializing in Cavity Substrate PCBs, we commit to delivering outstanding product quality and exceptional service. We are dedicated to collaborating with our customers to forge a brighter future together.

Cavity Substrate PCB Manufacturer Quotation

Accurately obtaining a quote for Cavity Substrate PCB manufacturing is crucial in selecting the right manufacturer. Key factors impacting the quote include material selection, manufacturing process complexity, specification requirements, and order quantity. To ensure precision in the quote, it is essential to provide accurate information to the manufacturer.

Reputable Cavity Substrate PCB manufacturers typically have transparent pricing structures. They present a detailed breakdown of project costs, outlining included services. This transparency aids customers in understanding the value and services associated with the quoted price.

Leading manufacturers boast professional customer service teams that attentively listen to customer needs. These teams collaborate with customers to comprehend their requirements and offer customized solutions with corresponding competitive quotes.

Choosing the right manufacturer involves factors beyond pricing, such as reputation and product quality. Established manufacturers often possess certifications like ISO, indicating adherence to industry standards and the production of reliable products.

To obtain an accurate quote, clear communication and precise information on requirements are essential. Opting for a reputable manufacturer ensures transparent pricing, high-quality products, and professional customer service, maximizing return on investment.

Frequently Asked Questions about Cavity Substrate PCB

What exactly is a Cavity Substrate PCB?

A Cavity Substrate PCB is a crucial component in modern electronics, featuring specialized cavities to house critical components. It provides a robust foundation for electronic devices.

What types of Cavity Substrate PCBs are available?

There are several types, including Organic Cavity Substrates (utilizing organic materials), Ceramic Cavity Substrates (employing ceramic for high thermal conductivity), and Silicon Cavity Substrates (incorporating silicon for semiconductor properties).

Why choose Cavity Substrate PCBs over traditional boards?

In comparison, Cavity Substrates offer unparalleled advantages such as a compact design and improved thermal management, making them the preferred choice for modern electronic devices.

How are Cavity Substrate PCBs manufactured, especially in the context of motherboards and substrates?

The manufacturing process involves advanced techniques for motherboard integration and meticulous processes for substrate production, ensuring seamless integration and optimal performance.

How can I obtain quotes from Cavity Substrate PCB manufacturers?

Obtaining accurate quotes is a key consideration when sourcing Cavity Substrate PCBs. Leading manufacturers offer transparent pricing structures, reflecting the value and quality of their products.

What are some common misconceptions or concerns about Cavity Substrate PCBs?

Addressing misconceptions and concerns helps in demystifying this advanced technology, fostering a better understanding of its applications and benefits.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier