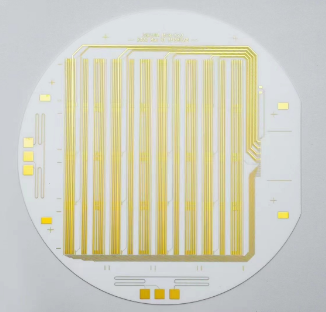

Advanced Ceramic substrate supplier, we mainly produce ultra-small bump pitch Ceramic substrate, ultra-small trace Ceramic substrate and Ceramic PCBs.

In the contemporary realm of electronic engineering, cutting-edge ceramic packaging substrates are emerging as a revolutionary element in PCB design. Acting as the crucial link between semiconductor chips and the broader PCB, these substrates transcend their role as mere connecting components; they stand as transformative forces in electronics design, reshaping the entire industry landscape.

Considered the nucleus of modern PCB technology, advanced ceramic packaging substrates surpass being a simple support structure. Instead, they function as a vital bridge connecting the semiconductor chip to the PCB, delivering unparalleled precision to enhance the performance and efficiency of electronic devices. This positions advanced ceramic packaging substrates as indispensable components in the intricate tapestry of today’s electronic designs.

Advanced ceramic packaging substrates have attracted much attention because they contain excellent electrical properties and miniaturization capabilities. Through these substrates, semiconductor chips can transmit signals more efficiently, implement more complex circuit layouts, and improve the performance of the overall electronic system. Its miniaturization characteristics also provide more space for the compact design of electronic equipment, meeting the needs of modern equipment for continuous compression of volume.

Apart from excelling in electrical performance and miniaturization, advanced ceramic packaging substrates also distinguish themselves through their exceptional thermal management capabilities. This attribute holds paramount importance for contemporary electronic devices, particularly high-performance processors and other power-intensive components. The remarkable thermal conductivity of ceramic materials facilitates the efficient dispersion and conduction of heat, thereby guaranteeing the stability and reliability of electronic devices during prolonged periods of operation.

They excel in performance, reliability and adaptability to advanced technologies compared to traditional PCBs. This innovation is pushing the entire field of electronic engineering forward, giving designers more room for creativity and flexibility.

In the changing era of electronic design, advanced ceramic packaging substrates have emerged and become a key component leading the future with their unparalleled precision, efficiency and innovation. They are not only a bridge connecting electronic components, but also an engine that drives the entire industry forward. As this technology continues to evolve, we can expect to see more electronic devices usher in new design styles catalyzed by this advanced substrate.

What are the types of advanced ceramic packaging substrates?

In the contemporary landscape of PCB engineering, advanced ceramic packaging substrates have garnered considerable attention owing to their versatility and exceptional performance. The spectrum of these substrates, ranging from aluminum oxide to silicon nitride and various other iterations, offers distinctive solutions for electronic designs, propelling device performance and reliability to unprecedented levels.

Alumina Ceramic Packaging Substrate

Among the pivotal variants of advanced ceramic packaging, the alumina substrate holds significant importance. Its outstanding insulation properties and thermal conductivity render it an ideal choice for effective thermal management. Alumina substrates excel in dissipating heat, thereby ensuring the stable performance of electronic devices.

Aluminum Tungstate Ceramic Packaging Substrate

The aluminum tungstate substrate emerges as an advanced ceramic material that has captured significant attention in electronic design. Noteworthy for its high-temperature stability and excellent electrical insulation properties, aluminum tungstate substrates find applications in extreme working conditions. They are commonly utilized in high-performance scenarios, including high-power amplifiers and microwave circuits.

Zirconia Ceramic Packaging Substrate

Zirconia substrates are highly valued for their elevated hardness and remarkable chemical stability. Particularly adept in applications requiring high reliability and durability, such as medical equipment and industrial control systems, zirconia substrates underscore their importance in critical electronic components.

The plethora of these advanced ceramic packaging substrates not only showcases material diversity but also underscores their unique capabilities in meeting specific design requirements. Whether addressing efficient thermal management or fulfilling high-frequency, high-power demands, these substrates consistently deliver exceptional performance and reliability for electronic devices.

When selecting advanced ceramic packaging substrates, a comprehensive understanding of the various types and their inherent characteristics is paramount to ensuring the success of electronic designs. Exploring the diverse features of these substrates allows for a nuanced grasp of their advantages in distinct application scenarios, laying a robust foundation for future innovations.

What are the advantages of advanced ceramic packaging substrates?

Advanced ceramic packaging substrates play a crucial role in contemporary PCB engineering, showcasing not only their exceptional potential but also presenting extraordinary advantages in enhancing the performance, miniaturization, and thermal management of electronic devices.

Enhance electrical performance

Advanced ceramic packaging substrates significantly improve the electrical performance of electronic devices through material selection and advanced manufacturing technology. The high thermal conductivity and superior insulation properties of ceramic materials effectively reduce energy loss during signal transmission, thereby ensuring higher electrical performance.

A critical challenge in electronic device design has always been thermal management, and advanced ceramic packaging substrates effectively address this concern. Their exceptional thermal conductivity and heat dissipation design allow for rapid heat conduction and dissipation, while also withstanding extreme temperature variations. This ensures that electronic equipment maintains outstanding performance even under high-load operation.

The combined benefits of miniaturization and superior thermal management lead to a substantial enhancement in the overall performance of electronic devices. Circuit stability and reliability are bolstered, enabling devices to excel in demanding, high-temperature conditions. Users can anticipate quicker data transfer speeds, reduced energy consumption, and extended service life.

The amalgamation of these advantages not only propels electronic equipment towards heightened advancement and reliability but also provides robust support for future innovation. Undoubtedly, in the progression of electronic engineering, this technology stands as a pivotal driving force propelling the industry forward.

Why choose advanced ceramic packaging substrates?

In the realm of electronics design and manufacturing, the careful selection of circuit board types holds paramount importance. Advanced ceramic packaging substrates have emerged as a breakthrough, outclassing traditional PCBs and revolutionizing industry benchmarks. The following pivotal factors underscore the preference for advanced ceramic packaging substrates:

Unparalleled Performance

Advanced ceramic packaging substrates exhibit exceptional performance characteristics, endowing electronic devices with heightened reliability and efficiency. Their inherent material properties enable them to endure elevated temperatures and voltages, positioning them as robust performers in challenging environments. This heightened performance is particularly crucial for applications demanding both high reliability and intricate operational capabilities, establishing ceramic packages as the preferred choice.

Compactness advantage

Relative to traditional PCBs, advanced ceramic packaging substrates offer greater compactness in design. Due to the high degree of integration of ceramic materials, they support smaller designs and are suitable for the trend of modern electronic devices becoming increasingly compact. The space savings provided by this compactness are particularly critical in mobile devices, drones, and other small electronics.

Adaptability to cutting-edge technology

Advanced ceramic packaging substrates provide an ideal platform for applications using leading-edge technologies. Not only are these substrates able to accommodate higher density components, they also support high frequencies and high-speed transmission, making them ideal for handling advanced communications and processor technologies. For projects that need to meet future technological challenges, advanced ceramic packaging substrates provide a reliable technology foundation.

Redefining industry standards

Advanced ceramic packaging substrates redefine industry standards through excellence in performance, compactness and technology adaptability. They not only provide more advanced solutions, but also provide an innovative platform for electronic designers and manufacturers, driving the entire industry forward.

Among circuit board options, advanced ceramic packaging substrates stand out for their superior performance, compactness and adaptability to cutting-edge technologies. As a key component of electronic design, they not only improve device performance but also pave the way for future innovation, becoming an important choice in today’s electronic engineering field.

How to manufacture advanced ceramic packaging substrates?

In modern PCB engineering, advanced ceramic packaging substrates play a key role, and their manufacturing process is full of complex and sophisticated technologies. Here’s a closer look at the process:

Motherboard manufacturing

The manufacturing of motherboards involves two key processes, subtraction and addition. The subtractive manufacturing process focuses on carving out the desired shape by removing excess material, which requires highly precise control. In contrast, the additive manufacturing process builds motherboards by stacking materials layer by layer, including advanced ceramic materials.

What are the application areas of advanced ceramic packaging substrates?

Advanced ceramic packaging substrates play a crucial role as integral components in modern PCB engineering, exhibiting remarkable versatility across various industries. Whether in consumer electronics, automotive systems, or medical equipment, these substrates have become omnipresent, providing exceptional performance and reliability to electronic devices. The following examples highlight the diverse applications of advanced ceramic packaging substrates in different sectors:

Consumer Electronics

In the domain of consumer electronics, advanced ceramic packaging substrates spearhead a technological revolution. These minute substrates, intricately embedded in devices like smartphones, tablets, and headsets, not only facilitate higher integration but also excel in miniaturized designs, thereby augmenting the overall user experience.

Medical Equipment

The medical field, with its stringent demands for reliability and high performance, heavily relies on advanced ceramic packaging substrates in medical devices. For instance, high-density interconnect technology employed in medical imaging equipment ensures exceptional performance in intricate medical environments while maintaining precise signal transmission.

Industrial Automation

Within the realm of industrial automation, advanced ceramic packaging substrates find extensive use in sensors and controllers. Their corrosion resistance and high temperature tolerance make them an optimal choice for harsh industrial environments, ensuring the dependable operation and longevity of equipment.

These practical examples vividly showcase the extensive applications of advanced ceramic packaging substrates across diverse industries. The adaptability and dependability of these substrates not only offer flexibility in electronic device design but also catalyze innovation across different sectors. As technology progresses, these substrates will undoubtedly play a pivotal role in propelling advancements in various fields, opening up new possibilities for future electronic designs.

Where to find advanced ceramic packaging substrates?

In the quest for top-tier advanced ceramic packaging substrates, selecting trustworthy channels is paramount. As a dedicated supplier committed to delivering outstanding solutions, we highly advise placing emphasis on the following key areas to ensure the success of your project:

Identify Reputable Manufacturers and Distributors

Prioritize suppliers with solid reputations and extensive experience. Thoroughly examine the track record of potential manufacturers to gauge their standing in the industry and ascertain whether they are recognized for consistently delivering high-quality ceramic packaging substrates.

Make decisions based on industry recommendations and reviews

Rely on industry recommendations and customer reviews to learn about the success of other projects. This helps confirm whether a potential supplier meets your project’s needs and provides you with confidence knowing you are choosing a reliable partner.

Consider the supplier’s technical capabilities

Ensure suppliers have advanced technical capabilities and production facilities to support the manufacture of high-quality ceramic packaging substrates. Advanced technology and equipment can directly affect the performance and reliability of the final product.

View supplier’s product range

Gain a thorough understanding of your supplier’s product portfolio to ensure the availability of advanced ceramic packaging substrates that align with your project requirements. Opting for a supplier with a diverse range of products can enhance the likelihood of meeting the varied demands of different projects.

Gain insights into your vendor’s customer support and services

Consider the supplier’s customer support and after-sales service. This includes technical support, customization options, and assistance throughout the project lifecycle. A proactive and responsive supplier can significantly mitigate project risk.

Choose a supplier that fits your project

Ultimately, choose a vendor that matches your project needs. Make your decision more informed by ensuring that your supplier can provide the best solution, taking into account project size, budget and technical requirements.

As a supplier to our company, we support your projects with high-quality advanced ceramic packaging substrates. We are committed to high standards of manufacturing and customer satisfaction, providing a reliable foundation for your electronic designs. Choosing us is a guarantee of stability and innovation.

Ceramic packaging substrate

What is the quote for advanced ceramic packaging substrates?

When selecting advanced ceramic packaging substrates, understanding their price quotes is key to making an informed decision. A thorough understanding of the cost considerations that influence these substrate quotes is a necessary step to ensure project success. Below is an in-depth look at the key factors behind quotes for advanced ceramic packaging substrates.

Effect of board type

The cost of advanced ceramic packaging substrates is primarily determined by the chosen board type. Various ceramic materials, such as aluminum oxide and silicon nitride, exhibit distinct physical and electrical properties, leading to variations in costs. It is imperative for readers to meticulously assess their project requirements in order to opt for the most fitting ceramic material, while also considering cost implications.

Complexity Considerations

The complexity of ceramic packaging substrates has a significant impact on their price quotes. Complex designs, multi-layer structures, and high-density interconnects can all lead to increased complexity in the manufacturing process, affecting costs. Readers need to find a balance between actual needs and costs to ensure that the selected design meets performance requirements while keeping costs under control.

Volume Pricing Complexity

Production volume is another important factor that affects the quotation. Typically, mass production reduces unit cost because production lines are more efficiently utilized. However, for small-scale or customized projects, the cost may be relatively high due to lower production efficiency. When choosing a production scale, readers need to consider project needs and cost-effectiveness.

Use of high-end technology and materials

Advanced ceramic packaging substrates often incorporate the latest technology and high-end materials to achieve superior performance. The use of these technologies and materials will directly affect the manufacturing cost of the substrate. Readers need to weigh the benefits of advanced technologies and materials against cost to ensure that the chosen substrate provides the best balance of performance and affordability.

Cost of customization options

For projects requiring custom design, costs may increase. Custom options often require additional engineering and manufacturing steps, affecting the final quote. In the early stages of a project, readers need to identify the customization requirements of the project and have a clear understanding of its impact on costs.

By in-depth understanding of the above factors, readers can more fully understand the quote structure of advanced ceramic packaging substrates. Such understanding not only helps avoid potential cost pitfalls, but also enables informed choices in project decisions, ensuring projects achieve the best balance between performance and cost.

Advanced Ceramic Package Substrate FAQs

As the electronic landscape continues to evolve, Advanced Ceramic Packaging Substrates have emerged as a key player in reshaping PCB engineering. To provide clarity and insight, we address some common queries surrounding these cutting-edge substrates.

Can Advanced Ceramic Packaging Substrates be customized for specific applications?

Yes, these substrates are highly customizable to meet specific design requirements, making them versatile for various applications across industries.

Can these substrates accommodate high-density interconnects?

Absolutely. Advanced Ceramic Packaging Substrates excel in supporting high-density interconnects, making them suitable for intricate electronic designs.

How do different types of Advanced Ceramic Packaging Substrates vary?

Variants such as Alumina and Silicon Nitride exhibit distinct characteristics catering to specific design needs. Alumina, for instance, emphasizes electrical insulation, while Silicon Nitride excels in thermal conductivity. The choice depends on the application requirements.

What advantages do Advanced Ceramic Packaging Substrates bring to electronic devices?

These substrates enhance electrical performance, enable miniaturization, and excel in thermal management. Their use translates to more efficient and reliable electronic devices, particularly in applications where space and heat dissipation are critical factors.

What are Advanced Ceramic Packaging Substrates?

Advanced Ceramic Packaging Substrates are integral components in modern PCB engineering, serving as essential bridges between semiconductor dies and the broader PCB. These substrates, crafted from advanced ceramic materials like Alumina and Silicon Nitride, redefine electronic design landscapes with their precision and efficiency.

What types of Advanced Ceramic Packaging Substrates are available?

Explore a diverse range of Advanced Ceramic Packaging Substrates, from Alumina to Silicon Nitride variants. Each type offers unique features catering to specific design requirements, promising elevated performance and reliability in electronic devices.

How do Advanced Ceramic Packaging Substrates outshine other board types?

Understand the comparative advantages of Advanced Ceramic Packaging Substrates over traditional PCBs. Witness their superiority in performance, compactness, and adaptability to cutting-edge technologies, reshaping industry standards.

What factors influence the quotes for Advanced Ceramic Packaging Substrates?

Navigate the intricacies of cost considerations influencing quotes for Advanced Ceramic Packaging Substrates. Unravel the complexities of pricing based on substrate type, complexity, and production volumes, aiding readers in informed decision-making.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier