Semiconductor Substrate Vendor . the Package Substrate will be made with BT base, Showa Denko and Ajinomoto High speed base materials.and other high speed materials.

A semiconductor substrate, commonly known as a semiconductor substrate, stands as a foundational element in the realm of printed circuit board (PCB) engineering, providing a robust underpinning for contemporary electronic equipment. Its introduction represents a profound innovation in electronics, introducing unparalleled flexibility and performance advantages to the design and manufacturing of diverse devices.

Semiconductor substrates play a pivotal role in the construction of electronic devices, serving not only as physical support but also as a crucial conduit for information flow and signal transmission. Leveraging superior electrical conductivity and stable physical properties, semiconductor substrates facilitate the reliable connection of electronic components, forming intricate circuit networks.

The significance of semiconductor substrates stems from the unique properties of their materials. Those fashioned from semiconductor materials not only exhibit excellent electrical conductivity but also harness the special characteristics of semiconductors. This enables electronic devices to achieve heightened performance and lower power consumption, providing crucial support for the miniaturization and high integration of modern electronic devices. This foundational material choice has been instrumental in the rapid development of smartphones, computers, and other portable devices integral to our daily lives.

Beyond their electrical properties, semiconductor substrates excel in heat dissipation. Given the substantial heat generated by electronic equipment during operation, the superior heat dissipation performance of semiconductor substrates ensures the stable operation of equipment under high-load conditions.

What types of semiconductor substrates are there?

Semiconductor substrates stand as essential elements in the realm of printed circuit board (PCB) engineering, finding extensive applications across diverse fields. These substrates come in various types, with rigid, flexible, and rigid-flex being the primary categories.

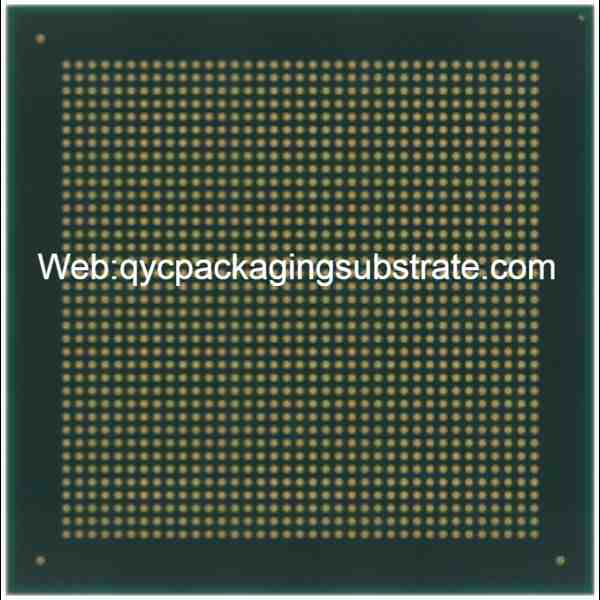

Semiconductor substrate

In contrast, flexible semiconductor substrates have garnered significant attention due to their flexibility and lightweight nature. Crafted from thin film materials like polyimide (PI), these substrates exhibit outstanding bending and stretchability. Their suitability extends to applications with stringent space and weight constraints, such as wearable devices, curved displays, and medical devices.

This type of substrate is structurally composed of strong, hard portions and soft, bendable areas, giving it an ideal balance of adaptability and performance. Rigid-flexible semiconductor substrates are often used in complex devices that require both mechanical strength and flexibility, such as foldable mobile phones and automotive electronic systems.

Different types of semiconductor substrates present unique design and manufacturing challenges and advantages. Rigid substrates excel in high-density integrated circuits and complex circuit designs, while flexible substrates are more suitable for scenarios that require bending and lightweight designs. Rigid-flexible substrates provide comprehensive solutions for some special applications.

The extensive variety of semiconductor substrates offers a wide range for innovation within the electronics industry. Engineers and designers have the freedom to select the most fitting substrate type tailored to specific application requirements, fostering a continuous progression of technology. This adaptability and versatility underscore the indispensable and critical role that semiconductor substrates play in the manufacturing of contemporary electronic devices.

What are the advantages of semiconductor substrates?

Secondly, semiconductor substrates have unique advantages in achieving high-density layout. Its advanced manufacturing process and material selection allow electronic components to be arranged more closely on the board, effectively reducing the overall size. This high-density design not only helps improve the performance of the circuit board, but also provides the possibility of lightweighting and miniaturization of electronic devices, meeting the needs of modern consumer electronics for compact designs.

Finally, the flexibility of semiconductor substrates is one of their compelling features. Compared with traditional rigid sheets, semiconductor substrates can better adapt to complex shapes and curves, providing engineers with greater design freedom. This flexibility not only has advantages in the appearance design of electronic devices, but is also particularly important when meeting special application scenarios and customization needs.

These advantages of semiconductor substrates make them the first choice in many electronic applications. From high-performance computers to mobile devices, from medical instruments to communication equipment, semiconductor substrates have demonstrated their excellent technical characteristics. As electronic engineers, fully understanding and utilizing these advantages of semiconductor substrates will help drive innovation, improve product performance, and meet the needs of the evolving electronics market.

Why choose semiconductor substrates instead of other board materials?

In today’s diversified applications in electronic engineering, why to choose semiconductor substrates instead of other board materials has become a matter of great concern. After an in-depth analysis of the reasons for choosing semiconductor substrates in different application scenarios, it is not difficult to find that its significant advantages in performance and reliability are the main driving forces for its widespread application.

First, semiconductor substrates excel in performance and become the preferred base material for many electronic devices. Its unique electrical properties, thermal conductivity and stable transmission characteristics of high-frequency signals make it shine in high-performance and high-frequency applications. Especially in the fields of modern communication equipment, wireless networks and high-performance computing, semiconductor substrates can meet stringent requirements for signal transmission speed and data processing capabilities, far exceeding the limitations of other traditional boards.

Secondly, semiconductor substrates have demonstrated excellent performance in terms of reliability and have become the first choice in various key application fields. In extreme environments, such as high temperature, high humidity, and even extreme cold, semiconductor substrates can maintain stable performance and ensure the normal operation of electronic devices. This makes semiconductor substrates popular in fields such as aerospace, medical equipment, and automotive electronics, where equipment reliability requirements are critical.

In addition, semiconductor substrates also have excellent dimensional control and manufacturing accuracy, making them even more advantageous in high-density circuit board design. With the trend of electronic devices becoming increasingly miniaturized and lightweight, the high degree of integration of semiconductor substrates has become an ideal choice to achieve this goal. Its superior manufacturing precision also helps reduce line delays in electronic devices and improves overall performance.

Overall, the reasons for choosing semiconductor substrates over other board materials can be summarized as their superior performance, reliability, and manufacturing accuracy. In different application scenarios, semiconductor substrates can show unique advantages and provide strong support for modern electronic engineering. In the pursuit of smaller, lighter, and faster electronic products, semiconductor substrates are undoubtedly one of the key elements driving technological innovation and development.

How are semiconductor substrates made?

The manufacturing of semiconductor substrates is a complex and precise project, involving two key components: motherboard and substrate. Here’s an in-depth look at both aspects of the manufacturing process:

Motherboard manufacturing process

In the motherboard manufacturing process, material selection is a crucial step. High-quality fiberglass reinforced resin is usually used as the base material to ensure the stability and reliability of the motherboard. In addition, copper foil with excellent electrical conductivity is selected as the material of the main conductive layer to improve the efficiency of electronic signal transmission.

Lamination process

The lamination process of the motherboard is to precisely superimpose different layers of materials and perform a high-temperature and high-pressure lamination process to tightly combine the layers. This helps improve the mechanical strength and durability of the motherboard while ensuring the stability of signal transmission.

Advanced craftsmanship and technology

Modern motherboard manufacturing employs many advanced processes and technologies to meet ever-increasing performance demands. This includes the use of advanced microfabrication technologies, such as micro-circuit manufacturing and multilayer PCB design, to achieve more functions and connections in limited space.

Manufacturing process of substrate

The fabrication of substrates first involves appropriate material selection. Common substrate materials include silicon and aluminum nitride, which have excellent thermal conductivity and electrical properties. Selecting the appropriate substrate material is critical to the performance of semiconductor devices.

The process of manufacturing a substrate involves cutting, cleaning and coating the selected material. During this process, advanced semiconductor manufacturing processes such as photolithography, etching, and deposition are used to accurately form circuit structures and devices.

After the substrate is manufactured, rigorous inspection and testing is performed to ensure quality and performance. This includes the use of high-precision instruments to inspect electrical properties, dimensions and surface quality. Any substandard substrates are discarded to ensure the reliability of the final product.

The manufacturing process of semiconductor substrates is a precise and technology-intensive project, which continuously promotes the development of the electronic field with the help of advanced materials and processes. Through the above manufacturing steps, the semiconductor substrate can achieve high performance and reliability, providing strong support for various electronic devices.

What are the applications of semiconductor substrates?

Semiconductor substrates, as the core component of printed circuit board (PCB) engineering, are playing an indispensable role in various fields. Its wide range of applications in many fields, including but not limited to consumer electronics, communications and medical care, provide strong support for modern life and technological development.

Consumer electronics field

Serving as the fundamental component within printed circuit board (PCB) engineering, semiconductor substrates play an essential and irreplaceable role across diverse fields. Their extensive applications, spanning consumer electronics, communications, and medical care, offer robust support for both the fabric of modern life and the trajectory of technological development.

Communication field

In the realm of consumer electronics, semiconductor substrates stand as crucial components within an array of electronic devices. Products ranging from smartphones and tablets to TVs and home appliances heavily depend on semiconductor substrates for intricate circuit connections and data processing. Leveraging the high density and performance advantages of semiconductor substrates results in consumer electronics that are not only more compact and efficient but also equipped with advanced functionalities.

Medical field

The application of semiconductor substrates makes medical equipment more intelligent and accurate, providing strong support for medical research and diagnosis.

Overall, the wide application of semiconductor substrates in many fields provides strong support for the technological development of modern society. It is not only the foundation of electronic products, but also a catalyst for technological innovation and industrial upgrading.

In the current era of swift technological progress, the extensive utilization of semiconductor substrates has not only become ubiquitous but has also unlocked the gateway to a future marked by exhilarating technological innovations and groundbreaking industry advancements.

Where exactly can I find semiconductor substrates?

In the pursuit of excellence in electronic engineering endeavors, securing a dependable semiconductor substrate supplier stands as a pivotal step towards ensuring the success of a project. The choice of a semiconductor substrate supplier transcends a mere transaction; it represents a strategic decision that profoundly impacts the overall quality and reliability of the entire project.

To identify a fitting semiconductor substrate supplier, a comprehensive exploration of the supply market is imperative. This involves delving into industry reports, online resources, and technology forums to gain insights into the key players currently dominating the market and their respective business reputations. Leveraging these channels enables us to gather feedback from fellow electronic engineers and companies, shedding light on the performance and service levels of different suppliers.

Armed with research findings, readers are directed to concentrate on semiconductor substrate suppliers, underscoring the advantages of selecting our company. Our firm takes pride in its unwavering commitment to ensuring customers receive top-notch products, a commitment grounded in years of experience and excellence within the semiconductor substrate domain.

Furthermore, it is paramount to underscore the significance of opting for high-quality suppliers. In the realm of electronic engineering, the quality of foundational materials directly influences the performance and reliability of the entire system. By aligning with high-quality semiconductor substrate suppliers, we guarantee that the materials sourced meet the highest standards, boasting stable electrical performance, exceptional durability, and superior heat dissipation characteristics.

In addition to quality, the supplier’s technical support and after-sales service are also crucial. Our company is characterized by providing a full range of technical support, always working closely with customers from initial project consultation to after-sales service after delivery.

In the decision-making process, selecting a semiconductor substrate supplier transcends a mere cost consideration; it represents a commitment to the success of the entire project. Opting for our company as a trusted semiconductor substrate supplier extends beyond a transactional relationship, promising a partnership deeply rooted in mutual success. We are dedicated to collaboratively advancing the innovative landscape of electronic engineering, assisting customers in achieving heightened success within an intensely competitive market.

In the fiercely competitive field of electronic engineering, the choice of a dependable semiconductor substrate supplier stands as a crucial element in ensuring project success. Opting for our company ensures not only the delivery of top-notch semiconductor substrates but also access to premier technical support and enduring partnerships. As we anticipate future electronic engineering endeavors, we eagerly anticipate the opportunity to work hand-in-hand with readers in shaping a brighter and more successful future.

What is the quote for semiconductor substrates?

While exploring the complexity and breadth of applications of semiconductor substrates, understanding their price quotes is a critical part of electronics engineering budgeting and decision-making. The following is basic information about semiconductor substrate quotations, as well as an in-depth analysis of the factors that affect prices, designed to help readers more fully understand the cost structure of this key area.

The quotation of semiconductor substrates is affected by many factors, some of which can be summarized as the following aspects:

Material selection: The quotation of semiconductor substrates first depends on the selected materials. High-performance, specially treated materials often result in higher costs, while some standard materials may be more affordable.

Number of layers and complexity: The number of layers and complexity of the substrate directly affects its manufacturing difficulty. Substrates with multi-layer and complex structures usually require more processes and higher technical requirements, thus affecting the final price.

Manufacturing process: Different manufacturing processes and technical requirements can also have a significant impact on the quotation. Advanced lamination techniques, special handling steps and high-precision machining processes can increase manufacturing costs.

Special requirements and custom designs: If the substrate needs to meet special industry standards, is a custom design, or has unique special requirements, these factors may result in additional costs.

Supplier’s geographical location: The costs of manufacturers in different geographical locations may vary, which affects the final quotation of semiconductor substrates. Some regions have lower production costs, while others may offer higher-end technology and services.

Factors affecting price

The price of semiconductor substrates is not static and is affected by a variety of factors related to market and technology development:

Market demand: The degree of industry demand for semiconductor substrates will directly affect its market price.

The introduction of new technologies sometimes increases costs, but as they become more common, prices may fall.

Competitive landscape: The competitive landscape in the market is also a factor in price fluctuations. Fierce competition may prompt manufacturers to adopt different pricing strategies, thereby affecting the market price of semiconductor substrates.

Global economic conditions: Global economic fluctuations and uncertainties will also have an impact on the raw material prices and manufacturing costs of semiconductor substrates.

By delving into fundamental insights on semiconductor substrate quotations and the determinants influencing pricing, readers can cultivate a more profound comprehension of the cost dynamics within this domain. Armed with this knowledge, individuals can make more informed decisions in their electronic engineering projects. Taking these pivotal factors into account during the semiconductor substrate selection process facilitates the attainment of an optimal equilibrium between performance and economic considerations.

Some frequently asked questions (FAQs) about semiconductor substrates

What is the difference between semiconductor substrate and traditional PCB board?

Semiconductor substrates serve as fundamental materials uniquely designed for integrated circuits, surpassing traditional PCB boards in aspects such as superior heat dissipation, heightened density, and increased flexibility. Unlike conventional PCBs primarily utilized for supporting and connecting electronic components, semiconductor substrates are specifically engineered to optimize the performance of integrated circuits. Their enhanced capabilities contribute to more efficient and high-performance electronic systems.

Why choose semiconductor substrates instead of other board materials?

Semiconductor substrates stand out for their exceptional heat dissipation properties, a critical factor for the optimal performance of high-end electronic devices. Beyond efficient heat management, these substrates boast higher integration density and enhanced flexibility, positioning them as ideal choices for cutting-edge electronic engineering projects.

How complex is the manufacturing process of semiconductor substrates?

The fabrication of semiconductor substrates involves multiple complex steps. From material selection, lamination process to the application of advanced processes and technologies, every link requires highly precise and professional technical support. The complexity of the manufacturing process directly affects the performance and quality of semiconductor substrates.

What applications are semiconductor substrates suitable for?

Semiconductor substrates are widely used in many fields. From consumer electronics, communication equipment to medical devices, semiconductor substrates can provide excellent performance and meet the needs of different industries for highly integrated circuits.

How to choose a reliable semiconductor substrate supplier?

Choosing a reliable semiconductor substrate supplier is crucial. When selecting a supplier, consider its reputation in the industry, production processes and product quality. Working with a supplier with extensive experience and a good reputation helps ensure a successful project.

What factors affect the quotation of semiconductor substrates?

The pricing of semiconductor substrates is influenced by numerous factors, encompassing the expenses associated with chosen materials, intricacies involved in the manufacturing process, and the prevailing market demand. When seeking a quotation, it is imperative to have a comprehensive understanding of these factors to formulate a judicious and realistic budget.

What is the future trend of semiconductor substrates in the electronics industry?

Looking ahead, as the electronics industry continues its rapid evolution, semiconductor substrates are poised to undergo increased scrutiny for innovation and performance enhancements. Anticipated advances in materials and manufacturing technologies are likely to emerge, elevating the significance of semiconductor substrates within electronic devices. The future holds the promise of these substrates assuming a more pivotal role as they adapt to and drive the ongoing advancements in electronic technologies.

What issues should we pay attention to when designing circuits for semiconductor substrates?

In circuit design, careful attention must be devoted to the heat dissipation needs of the semiconductor substrate, the layout of the circuit, and the potential effects on signal integrity. Thoughtful consideration of these factors is crucial to optimizing the benefits of semiconductor substrates in circuit design.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier