BT package substrate Manufacture. We use advanced Msap and Sap technology to build High multilayer interconnection substrates from 2 to 20 layers.

The semiconductor industry has consistently maintained its position at the vanguard of rapid development and innovation, with semiconductor packaging substrates assuming a pivotal role in this trajectory. These substrates serve as the essential foundation and interconnection for semiconductor chips, and their quality, performance, and reliability exert a direct and profound influence on the effectiveness and sustainability of the entire electronic device. Consequently, it is impossible to understate the significance of semiconductor packaging substrates in this domain.

This article delves into a particularly noteworthy packaging substrate that has been gaining considerable attention: the BT packaging substrate. BT represents a promising technology with the potential to revolutionize the conventional methods of semiconductor packaging. We will demystify the world of BT packaging substrates and thoroughly examine their unique characteristics, advantages, and application areas. As we embark on this exploration, you will gain insight into how BT packaging drives innovation and sustainability within the semiconductor industry. So, let us delve deeper into the realm of BT packaging substrates to gain mastery of this cutting-edge technology shaping the future.

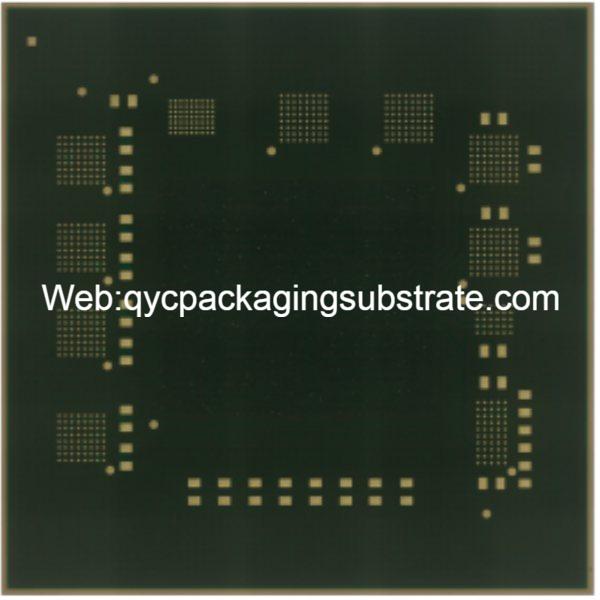

BT package substrate

What is BT packaging substrate?

BT packaging substrate, full name Bismaleimide Triazine, is a material widely used in the fields of semiconductor manufacturing and electronic packaging. BT packaging substrates stand out for their outstanding performance and versatility. Let’s take a closer look at this compelling material.

Explain the full name and meaning of BT packaging

The full name of BT package “Bismaleimide Triazine” is derived from its main chemical composition. This material is composed of three different structural units, namely triazine, maleimide, and bismaleimide. This chemical makeup gives BT packaging substrates excellent thermal stability and mechanical strength. Its unique structure also gives it excellent performance in high temperature and high frequency applications.

Describe the application of BT packaging substrates in the semiconductor industry

BT packaging substrate plays a vital role in the semiconductor industry. It is widely used in critical applications in semiconductor packaging, chip packaging, and electronic manufacturing. This substrate is ideal for advanced packaging technologies as it offers significant advantages in several aspects.

First, the thermal stability of BT packaging substrates makes them ideal for high-temperature packaging processes. Semiconductor devices generate a lot of heat when operating, and BT substrates can maintain their physical and electrical properties at high temperatures, ensuring the reliability and stability of the device.

Secondly, the BT packaging substrate has excellent electrical properties. It offers low dielectric loss and excellent high-frequency performance, making it popular in high-speed data transmission and communications equipment.

Most importantly, the sustainability of BT packaging substrates. Its material production process is relatively environmentally friendly and meets the requirements of modern sustainability practices. This is crucial for the sustainability and green development of the electronics manufacturing industry.

In summary, BT packaging substrates are key materials in the semiconductor and electronics manufacturing fields and are highly regarded for their unique chemical makeup and excellent performance. Whether for high-performance applications in high-temperature environments or for sustainable manufacturing practices, BT packaging substrates play an important role in shaping future developments in electronics.

Characteristics of BT package substrate

Physical Characteristics: Exploring the Size and Structure of BT Package Substrates

The physical properties of BT packaging substrates play a vital role in semiconductor manufacturing. First, its size and structure provide reliable support and connections for electronic devices. BT packaging substrates usually come in standard sizes to accommodate different packaging needs, from microchips to large circuit boards. Its multi-layer structure allows it to accommodate complex circuits and provide interconnections between circuit elements.

Electrical Characteristics: Explain their effect on circuit performance

BT packaging substrate has excellent electrical characteristics in terms of circuit performance. Due to its low dielectric constant and low loss tangent, it provides excellent signal transmission performance. This means that electronic signals can be quickly propagated on the BT package substrate, reducing signal attenuation and delay, which helps to improve the working speed and reliability of the circuit. In addition, the BT packaging substrate also has excellent isolation performance, which helps reduce electromagnetic interference and crosstalk, thereby improving the stability of the circuit.

Material Properties: Discussing the Advantages of BT Materials

The material characteristics of BT packaging substrates set them apart as exceptional components in the realm of semiconductor packaging. BT, also known as aromatic polyester resin, is a high-performance insulating material celebrated for its remarkable thermal stability and mechanical robustness. It boasts the ability to withstand high-temperature procedures while retaining structural integrity, a vital attribute for the rigorous demands of semiconductor manufacturing processes. Furthermore, BT material exhibits outstanding chemical resistance, effectively guarding against the corrosive effects of various chemicals. This ensures the circuit board’s enduring stability and reliability over the long term.

In short, BT packaging substrates provide important support for semiconductor manufacturing with their outstanding physical, electrical and material properties. Its physical properties provide flexibility for different packaging needs, electrical properties improve circuit performance, and material properties ensure stability and reliability. These characteristics make BT packaging substrates the preferred material in semiconductor packaging, providing a solid foundation for the development of modern electronic devices.

BT package substrate

Advantages of BT packaging substrate

BT packaging substrates offer several significant advantages that are becoming increasingly important in the semiconductor industry. The three main advantages of BT packaging substrates will be introduced in detail below:

High Temperature Stability: BT packaging substrates excel in high-temperature environments, a critical attribute for semiconductor manufacturing. The semiconductor production process often involves elevated temperatures, and BT packaging substrates are adept at withstanding these demanding conditions. This high-temperature stability holds paramount importance for semiconductor devices operating continuously in electronic equipment, as it ensures their resilience under heavy loads and extends their service life.

Electrical Performance: BT packaging substrates offer substantial advantages to semiconductor and electronic equipment manufacturers by enhancing circuit performance. These substrates exhibit exceptional insulation properties, effectively mitigating interference and leakage current between circuits. This not only bolsters the overall performance of electronic devices but also contributes to improved battery life, reduced power consumption, and heightened energy efficiency. Electronic equipment manufacturers can leverage BT packaging substrates to achieve faster and more dependable circuit transmission, ultimately delivering an enhanced user experience.

Sustainability: In an era where sustainability garners increasing attention, the eco-friendly characteristics of BT packaging substrates have garnered significant interest. BT materials are low in environmental impact and generate minimal hazardous waste during manufacturing and disposal. This aligns with the sustainability objectives of numerous companies and aids in reducing adverse effects on the environment. Furthermore, the sustainability of BT packaging substrates contributes to decreased energy consumption, lower production costs, and reduced reliance on finite resources.

Overall, the high-temperature stability, improved electrical performance, and sustainability features of BT packaging substrates make it an important choice in the semiconductor manufacturing and electronics industries. These advantages help improve product performance, extend service life, reduce adverse impacts on the environment, and provide a sustainable foundation for future electronic development.

Future trends of BT packaging substrates

BT packaging substrate has always played a vital role in the semiconductor industry, but its future trends will further promote progress in the electronic field. The following are predictions of the future direction of BT packaging substrate technology and an emphasis on the continued innovation and sustainability practices required to realize these trends.

Predict the development direction of BT packaging substrate technology

High-density integration:In the future, BT packaging substrates will continue to develop towards higher density integration. This means more components and connections will be integrated into smaller packaging substrates to meet the growing performance demands of consumer electronics devices.

High frequency applications:With the popularity of 5G and the Internet of Things (IoT), BT packaging substrates will gradually adapt to higher operating frequencies. This requires improved electrical performance to ensure stable signal transmission, especially in RF applications.

Thinner and lighter:Future BT packaging substrates will be thinner and lighter to meet the needs of portable devices and wireless communication equipment. This will drive the development of new materials to enable smaller and lighter packaging substrates.

Thermal Management Innovation:As the power consumption of semiconductor devices increases, future BT packaging substrates will require more powerful thermal management technology to ensure that devices do not overheat. New cooling materials and technologies are expected to emerge to meet this need.

Emphasis on the importance of continuous innovation and sustainable practices

In order to realize the above trends and promote the development of BT packaging substrate technology, continuous innovation and sustainable practices will play a key role.

R&D and cooperation:Semiconductor manufacturers and packaging substrate suppliers need to continuously invest in research and development and seek new materials and processes. Cooperation is also key, as multi-party cooperation can accelerate the evolution of technology.

Environmental awareness:Sustainability practices will become increasingly important. The process of manufacturing BT packaging substrates requires more attention to environmental protection and reduction of waste and energy consumption. Recyclable materials and green manufacturing processes will become more attractive.

talent development:Future BT packaging substrate technology requires engineers and technicians with appropriate skills and knowledge. Training and education will help meet industry needs.

In short, the future of BT packaging substrate technology in the electronic field will be very bright. Through continuous innovation and sustainable practices, we can achieve higher performance, smaller and lighter packaging substrates, driving continuous progress in the electronics field. This future is full of hope and opportunities.

Summarize

In the semiconductor field, BT packaging substrate plays a vital role. This article has discussed the definition, characteristics, advantages and application cases of BT packaging substrate to help readers better understand its core position.

BT packaging substrate, a prominent technology in the realm of semiconductor packaging, garners acclaim for its outstanding performance attributes and diverse range of applications. Its remarkable high-temperature stability empowers it to deliver exceptional performance even in elevated-temperature environments, ensuring the steady operation of semiconductor devices under extreme conditions. Furthermore, the electrical properties inherent to BT materials contribute to the enhancement of circuit performance, thereby catalyzing the overall advancement of semiconductor devices. Beyond its technical prowess, the sustainable characteristics of BT packaging substrates play a pivotal role in mitigating environmental impact, firmly positioning it as a component of future sustainable development endeavors.

In order to promote progress in the semiconductor field, we encourage all parties to have a deep understanding of BT technology. Semiconductor manufacturers, engineers and researchers can drive innovation and performance improvements in semiconductor devices by continuously exploring the potential of BT packaging substrates. In addition, sustainable practices should be actively adopted to ensure that the future development of the semiconductor industry is consistent with environmental protection concepts.

In an evolving semiconductor market, BT packaging substrates not only play an important role currently, but will continue to lead the wave of technological innovation in the future. By deeply understanding BT technology and applying it to semiconductor manufacturing and design, we can jointly drive the semiconductor industry forward and create more powerful, reliable and sustainable electronic products to meet growing market demands.

BT packaging substrates represent the future of innovation and sustainability in the semiconductor industry. We encourage everyone to actively explore BT technology and contribute to the future of the semiconductor field while protecting our environment and creating a better world.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier