FC BGA substrate design rules and Semiconductor FC BGA substrate Firm. High multilayer FC BGA package substrate design reference rules. and High speed and high frequency material packaging substrate manufacturing. Advanced packaging manufacturing technique.

Semiconductor FC BGA (ball ball array) substrate is a technology component that plays a key role in semiconductor device manufacturing. It provides high-density connections for semiconductor chips in the form of solder ball arrays and has become an indispensable part of modern electronic products.

In the design and manufacturing of semiconductor devices, Semiconductor FC BGA substrates are widely used to solve the challenges of connection density and performance requirements. Through the design of the solder ball array, Semiconductor FC BGA substrate can achieve a large number of connection points in a small space, providing an ideal solution for the connection between the chip and other components.

The core of solder ball array technology lies in its tight layout and high-density characteristics, which allows semiconductor devices to integrate more functions and components in a smaller size. Compared with traditional connection methods, such as ordinary BGA (ball grid array) or QFN (leadless package), Semiconductor FC BGA substrate provides higher connection density and superior performance.

Due to its excellent performance and wide range of applications, Semiconductor FC BGA substrate has become the first choice for many electronic product designs. Whether it is smartphones, tablets, servers, or automotive electronics and industrial control, Semiconductor FC BGA substrates play an important role.

Overall, Semiconductor FC BGA substrate provides an ideal solution for the design and manufacturing of semiconductor devices through its high-density solder ball array connection method. It not only provides excellent connectivity performance, but also helps achieve miniaturization and high performance of electronic products.

What are the advantages of Semiconductor FC BGA substrate?

Semiconductor FC BGA (solder ball array) substrates offer many advantages in PCB engineering, including excellent performance in high-density connections, signal transmission performance and thermal management.

First, Semiconductor FC BGA substrate has compelling advantages in high-density connections. Using solder ball array connection technology, the substrate can achieve a large number of connection points in a relatively small area, thereby achieving high-density connections. This connection method not only saves space, but also improves the layout flexibility of the circuit board, allowing electronic devices to achieve more functions and component integration in a smaller size.

Secondly, Semiconductor FC BGA substrate performs well in signal transmission performance. It uses high-quality materials and advanced manufacturing processes to ensure the stability and reliability of signal transmission. This makes Semiconductor FC BGA substrate capable of meeting the needs of high-speed data transmission and high-frequency signal processing, providing reliable signal transmission support for various application scenarios.

In addition, Semiconductor FC BGA substrate also performs well in thermal management. It has good heat dissipation performance and can effectively manage the heat generated by the chip to maintain the stability and reliability of the device. This is especially important for high-performance electronic equipment, especially when running for a long time or working under high load, and can effectively prevent equipment damage due to overheating.

To sum up, Semiconductor FC BGA substrate has become an indispensable key component in electronic equipment due to its high-density connection, excellent signal transmission performance and excellent thermal management capabilities. Its outstanding performance provides a stable and reliable foundation for various application scenarios and promotes the continuous innovation and development of the electronics industry.

What is the manufacturing process of Semiconductor FC BGA substrate?

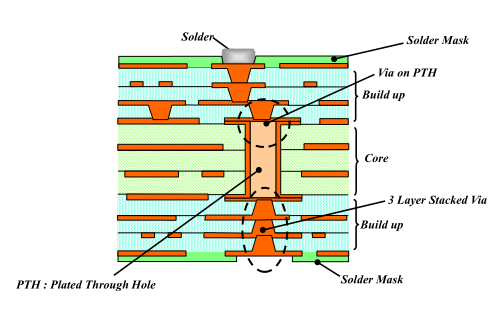

The manufacturing process of Semiconductor FC BGA substrate involves two key steps, namely the manufacturing of Motherboard and the manufacturing of Substrate. Here’s a closer look at how these two steps are accomplished, and what key steps were taken during the manufacturing of Substrate to ensure high-density connectivity and superior performance.

First, manufacturing the Motherboard of the Semiconductor FC BGA substrate is a critical step. This process often uses advanced printed circuit board (PCB) manufacturing technology. This technology ensures the stability and reliability of Motherboard to support subsequent semiconductor device integration.

At this stage, engineers will use high-precision production equipment to convert the circuit board design drawings into the actual Motherboard. This may involve layer-by-layer stacking, fine circuit layout, and advanced material applications to meet the design requirements of the Semiconductor FC BGA substrate.

Next, fabricating the Substrate for the Semiconductor FC BGA substrate is another critical step in the manufacturing process. At this stage, there are a series of precise process steps to ensure that Substrate can achieve high-density connections and excellent performance.

Design stage: Engineers will first design the layout of Substrate according to the requirements of the product, including the arrangement of the solder ball array and the design of the connection paths.

Cutting and shaping: Substrate manufacturing usually starts with a larger substrate, which is processed into the required shape and size through steps such as cutting and shaping.

Chemical treatment: Substrate undergoes a series of chemical treatments to enhance its surface properties and improve welding accuracy and reliability.

Gold plating process: In order to improve the reliability of the connection, the connection points on the Substrate are usually gold-plated to protect them from corrosion and oxidation.

Through these critical steps, manufacturers can ensure that Semiconductor FC BGA substrates meet the required standards in terms of high-density connectivity and superior performance.

Taken together, the manufacturing process of Semiconductor FC BGA substrate requires advanced manufacturing technology and precise process control to ensure its excellent performance in semiconductor equipment. The precise execution of these steps provides the basis for reliability and stability of semiconductor equipment.

FC BGA substrate design rules

In what application areas are Semiconductor FC BGA substrates widely used?

Semiconductor FC BGA substrate, as an advanced Package Substrate technology, plays a key role in various electronic devices and promotes continuous innovation and development of technology. The following are the applications of Semiconductor FC BGA substrates in several important fields and the promotion of technological innovation:

As an indispensable device in modern people’s lives, smartphones have extremely high requirements for performance and size. Semiconductor FC BGA substrate supports the miniaturization and feature enhancement of smartphones through its high-density connectivity and excellent signal transmission performance. Inside the mobile phone, the Semiconductor FC BGA substrate connects various key chips and modules, including processors, memory, cameras, etc., providing a solid foundation for the high-performance operation of the mobile phone.

Similar to smartphones, tablets also need to integrate more functions and performance into a limited space. The application of Semiconductor FC BGA substrate in tablet computers enables the device to achieve faster data processing speeds and higher graphics performance, providing users with a smoother experience.

In servers and data centers, performance and reliability are critical. Semiconductor FC BGA substrate plays an important role in connecting and transmitting data in these fields. It can support high-speed data transmission and processing, and has excellent heat dissipation performance to ensure the stable operation of servers and efficient operation of data centers.

With the rapid development of automotive electronics technology, Semiconductor FC BGA substrates have also begun to be widely used in the field of automotive electronics. In automotive electronic systems, Semiconductor FC BGA substrates connect various sensors, control units and communication modules to provide intelligence, safety and comfort functions for vehicles.

In these application fields, the wide application of Semiconductor FC BGA substrate not only meets the needs of electronic equipment for high performance and reliability, but also promotes continuous innovation and progress of technology. By continuously improving the design and manufacturing process of the substrate, manufacturers are able to provide more advanced and reliable Semiconductor FC BGA substrates, promoting the development and growth of the entire electronics industry.

What is the quotation of Semiconductor FC BGA substrate?

If you want to get a quote for Semiconductor FC BGA substrate, what are the ways you can try? What factors should you focus on when comparing prices and services?

Semiconductor FC BGA substrate is a key component of electronic equipment and has a wide range of applications in the market. To get a quote for your substrate, there are a number of avenues you can try, including:

Online search: Find manufacturers or suppliers related to Semiconductor FC BGA substrate through search engines or professional electronic equipment platforms. Such platforms usually provide the manufacturer’s product information, contact information, and quotation query functions, allowing you to directly obtain the information you need.

Attend industry exhibitions: Exhibitions in the electronics industry are usually one of the important ways to learn about the latest technologies and products. Participate in relevant exhibitions, communicate face-to-face with manufacturers and suppliers, directly understand product information and obtain quotations.

Consult industry experts: If you don’t know much about the market, you can consult industry experts or practitioners for their advice and recommendations. They may recommend some well-known manufacturers or suppliers and provide more detailed information and suggestions for quotations.

When comparing prices and services, here are some factors to focus on:

Quality and Reliability: As a key component, the quality and reliability of Semiconductor FC BGA substrate are crucial. It is necessary to pay attention to the manufacturer’s quality control system, production process and product certification information to ensure that the quality of the selected products meets the standards.

Technical support and service: Good technical support and after-sales service can help you solve problems encountered during use and ensure the stable operation of the product. Therefore, it is necessary to understand the technical support and after-sales service policies provided by the manufacturer or supplier.

Delivery cycle and inventory status: Based on your needs, you need to pay attention to the product delivery cycle and the supplier’s inventory status. Timely delivery and sufficient inventory ensure your production schedule runs smoothly.

Price and cost-effectiveness: Of course, price is also one of the important considerations when choosing a supplier. It is necessary to comprehensively consider the price, quality, technical support and other aspects of the product and select the supplier with the highest price/performance ratio.

To sum up, to obtain a quotation for Semiconductor FC BGA substrate, you can search online, attend exhibitions, or consult industry experts. When comparing prices and services, you need to focus on factors such as quality and reliability, technical support and service, lead time and inventory, and price and value for money to make an informed choice.

How to find a professional Semiconductor FC BGA substrate manufacturer?

When looking for a professional Semiconductor FC BGA substrate manufacturer, it is crucial to make sure you choose a reliable partner. Below are some channels and methods, as well as factors to consider carefully when selecting a manufacturer to ensure that your company’s needs are met.

Online Search: Use an Internet search engine to find information about Semiconductor FC BGA substrate manufacturers. Detailed keyword and specialized searches can help you find more precise results.

Industry exhibitions and events: Attending professional exhibitions and events in the electronics industry is a good way to meet manufacturers, learn about their products and technologies, and establish connections.

Industry forums and social media: Participate in industry-related online forums and social media groups to seek advice and recommendations from peers and learn about their experiences and opinions.

Reference industry professional publications: Read professional publications in the electronics industry, which may contain reviews and recommendations for manufacturers.

Recommendations and word-of-mouth: Ask for recommendations from peers, suppliers, industry experts, etc. to get their impressions and experiences with certain manufacturers.

Factors to pay attention to

Qualifications and Certifications: Carefully review a manufacturer’s qualifications and certifications to ensure they comply with industry standards and regulations.

Technical capabilities: Assess the manufacturer’s technical capabilities, including its expertise and innovation capabilities in the field of Semiconductor FC BGA substrates.

Quality Control: Understand the manufacturer’s quality control processes and standards to ensure products meet your requirements and standards.

Production Capabilities: Evaluate the manufacturer’s production capabilities to ensure they can meet your needs and deliver in a timely manner.

Customer service and support: Examine the manufacturer’s customer service level and support system to ensure that you can receive timely support during the cooperation process.

Price and lead time: Compare prices and lead times from different manufacturers to ensure you get a reasonable quote and delivery time while meeting quality requirements.

Contract conditions: Carefully review the contract conditions, including payment terms, warranty period, etc., to ensure that the rights and interests of both parties are fully protected.

By carefully considering these factors and making full use of various channels and methods, you can be more confident in finding a professional Semiconductor FC BGA substrate manufacturer to provide reliable support and solutions for the company’s electronic products.

Common problem

How is Semiconductor FC BGA substrate manufactured?

The manufacturing process of Semiconductor FC BGA substrate involves two key steps: producing the motherboard and the substrate itself. The motherboard is manufactured using advanced PCB fabrication techniques, ensuring stability and reliability. Substrate manufacturing includes design, cutting, chemical processing, and gold plating, ensuring high-density connections and excellent performance.

Where is Semiconductor FC BGA substrate widely used?

Semiconductor FC BGA substrate finds extensive applications in various electronic devices, including smartphones, tablets, computers, servers, network equipment, automotive electronics, and industrial control systems.

How can I find a reliable Semiconductor FC BGA substrate manufacturer?

You can find a reputable Semiconductor FC BGA substrate manufacturer through online searches, industry exhibitions, and referrals from industry experts and peers. When selecting a manufacturer, consider factors such as qualifications, technical capabilities, and customer feedback to ensure reliability and quality.

What factors influence the pricing of Semiconductor FC BGA substrate?

The pricing of Semiconductor FC BGA substrate is influenced by factors such as substrate material, design complexity, manufacturing process, and order quantity. It’s essential to obtain quotes from multiple manufacturers and compare prices and services before making a decision.

How reliable is Semiconductor FC BGA substrate?

Semiconductor FC BGA substrate undergoes stringent quality control and testing processes to ensure reliability and stability. It meets industry standards and is widely trusted for various electronic applications.

How do I choose the right Semiconductor FC BGA substrate manufacturer?

When selecting a Semiconductor FC BGA substrate manufacturer, consider factors such as their qualifications, technical expertise, manufacturing capabilities, and customer satisfaction. It’s essential to choose a manufacturer that aligns with your requirements and values quality and reliability.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier