We are Package Substrate Firm.Exploring Package Substrate Materials.Such as: Showa Dekno series: MCL-E705G, MCL-E-770G, Ajinomoto series: GX92R, GXT31R2, and so on. we are a professional package substrate maker.

In today’s digital age, electronic devices have become an indispensable part of our lives. Whether it is our smartphones, computers, or automotive control systems and communication equipment, their core lies in packaging substrate materials. These materials may not be well known, but they are the heart of electronic devices, providing them with support and performance. Therefore, it is crucial to understand the importance of these materials.

This article will take an in-depth look at packaging substrate materials, exploring the different types of materials, the impact of their selection, and applications in electronics. We’ll look at the characteristics of common materials such as rigid substrates, flexible substrates, and high-performance polymers, and explore their role in circuit performance, temperature management, and sustainability. In addition, we will explore the critical role of these materials in electronics, communications and the automotive industry, and how future trends in technology and sustainability will influence the choice of packaging substrate materials. In this article, we’ll take a closer look at these humble yet vital materials that advance the electronics industry.

Package substrate material

What is Package Substrate Material?

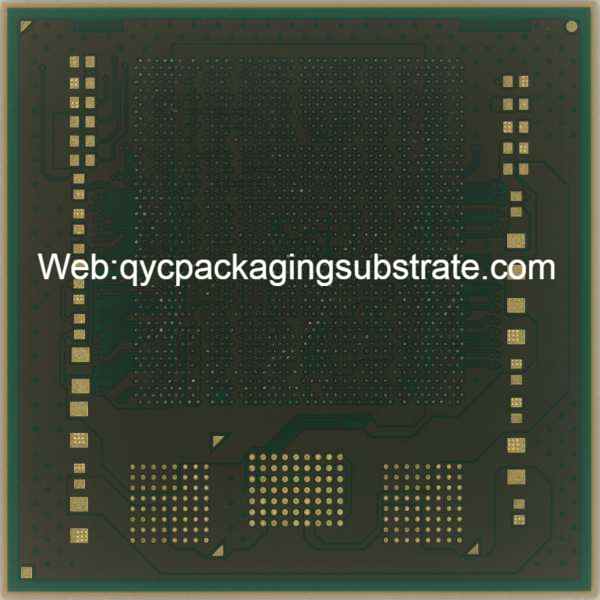

In electronics manufacturing, packaging substrate materials are key components used to support and connect electronic components. These materials are commonly used to make printed circuit boards (PCBs) and chip packages, where they provide a stable platform on which circuit components can operate safely and reliably. The choice of packaging substrate materials can influence circuit performance, thermal management, sustainability and cost-effectiveness, so they play a vital role in electronics manufacturing.

Packaging substrate materials are the basis of electronic devices. They support and connect electronic components and ensure the normal operation of the device. These materials not only provide physical support but also impact the performance and reliability of the circuit. For example, rigid substrates can provide stable support, while flexible substrates make devices more adaptable to bending and miniaturization needs. Material selection can also impact temperature management, which is critical for equipment in high-temperature environments. In summary, packaging substrate materials are at the heart of electronic devices, and their selection and design have a profound impact on device performance and reliability.

Common packaging substrate materials

Hard substrate: Discuss the characteristics of common hard materials such as FR-4

In the field of electronic packaging, rigid substrates are a common choice, with FR-4 materials being particularly prominent. FR-4 is a glass fiber reinforced composite material with excellent electrical properties and mechanical strength. Its high temperature resistance makes it a common choice in electronics, especially in PCB design. Rigid substrates provide superior stability and reliability, making them highly prized in high-performance electronic devices.

Flexible Substrates: An Introduction to the Flexibility and Application Areas of Flexible Materials

Flexible substrates are known for their flexibility, allowing them to be bent and bent to suit various design requirements. This material is particularly useful in compact electronic devices, such as wearables and curved screens. The application fields of flexible substrates are constantly expanding, providing greater freedom for innovative designs and making electronic devices thinner, lighter, more portable and more ergonomic.

High-Performance Polymers: Exploring the Role of High-Performance Polymers in Innovative Design

High-performance polymers are an advanced class of materials that play an important role in electronic packaging. These polymers offer excellent electrical properties, chemical resistance, and high temperature resistance. They are widely used in high-density circuit boards, RF packaging and special environment applications. The emergence of high-performance polymers has driven innovation in electronic design, allowing us to build more powerful and efficient electronic systems.

By understanding these common packaging substrate materials, engineers can better select and apply materials that fit their specific project needs, resulting in better designs and performance. This material selection is critical in terms of circuit performance, temperature management and sustainability.

Impact of material selection

Circuit Performance: Explain the impact of different materials on circuit performance

Selecting the appropriate packaging substrate material is critical to circuit performance. Rigid substrates such as FR-4 provide excellent mechanical stability while providing a high dielectric constant, which is important for high frequency circuits. Flexible substrates perform well in high-frequency applications because of their low dielectric constant and flexibility. High-performance polymer materials provide better signal integrity, thereby improving circuit performance.

Temperature Management: Exploring the Impact of Materials on Temperature Control

Temperature is critical to the performance and longevity of electronic devices. Different materials have different effects on temperature management. Rigid substrates usually have higher thermal conductivity, can effectively dissipate heat, and are suitable for high-temperature environments. Flexible substrates are more sensitive to temperature due to their thin profile and low thermal conductivity, making them suitable for low-power and lightweight applications.

Sustainability considerations: highlighting the impact of material selection on sustainability

In the current context of sustainable development, material selection is not only about performance, but also about environmental protection. Choosing packaging substrate materials that meet environmental standards is critical to sustainability. The environmental impact of the production, use and disposal of materials should be comprehensively considered to reduce waste and energy waste and promote the sustainable development of the electronics industry.

By gaining a deeper understanding of the impact of material selection on circuit performance, temperature management, and sustainability, engineers can make more informed choices about appropriate packaging substrate materials to meet the needs of specific applications, improve performance, and promote sustainable practices at the same time. This will help the electronics industry stand out in an ever-changing market.

Package substrate material

Package Substrate Application areas

Packaging substrate materials play an important role in various fields, and through different application cases, we can better understand their diversity and critical role.

Electronic product

Electronic products, such as smartphones, tablets, and TVs, are constantly pursuing smaller, higher-performance designs. Printed circuit boards (PCBs), the core of these devices, require reliable packaging substrate materials to ensure circuit performance, signal integrity and sustainability. The light, thin and short characteristics of organic substrate materials make them the first choice for modern electronic products.

Communication field

In communication devices, packaging substrate materials play a key role. Whether it is mobile phones, satellite communications equipment or data center servers, these devices rely on high-performance packaging substrate materials to ensure stable data transmission and communication quality. The high-frequency performance and signal integrity of organic substrate materials make them popular in the communications field.

Automobile industry

Automotive electronic systems are constantly evolving, from smart driving to in-car entertainment systems. The application of packaging substrate materials in automotive electronics is a key factor in ensuring vehicle performance and safety. The use of materials such as high-performance polymers in automotive electronic systems, such as on-board control units and in-car entertainment systems, is critical to ensuring vehicle reliability and performance.

Through application cases in these different areas, we can better understand the multiple roles of packaging substrate materials to meet the performance and sustainability needs of various electronic devices. This further emphasizes the criticality of material selection in different application areas to ensure optimal design and performance.

Summarize

Throughout this article, we dive into the critical nature of packaging substrate materials. These materials are core components of electronic devices and play a vital role in their performance, reliability and sustainability. We have looked at the different types of packaging substrate materials, including rigid substrates, flexible substrates and high-performance polymers, and their role in various application areas.

Emphasis on continuous innovation and sustainable practices to advance the electronics industry

As the electronics industry continues to evolve, we must continue to drive innovation to meet growing needs and challenges. The field of packaging substrate materials is no exception. Continuous innovation is key, including seeking new materials, processes and design approaches to improve performance and sustainability. At the same time, sustainable practices should also become industry standards to ensure that the manufacturing and use of electronic products are more environmentally friendly to meet the needs of modern society for sustainability.

In summary, packaging substrate materials play a vital role in the electronics industry. They not only drive technological advancements, but also drive our focus on innovative and sustainable practices. Through continuous innovation and sustainable practices, we can continue to improve the performance of electronic products, extend their lifespan, and reduce their impact on the environment,thus promoting the sustainable development of the electronics industry.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier