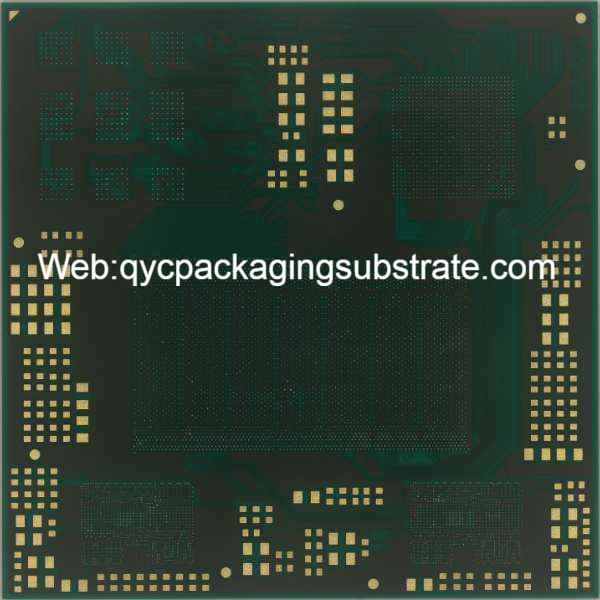

Packaging Substrate Suppliers, we offer package substrate prototypes up to mid-volume production. the best samllest via size are 50um. the best smallest gap are 9um. and Minimum trace are 9um too.

In today’s rapidly developing electronics field, packaging substrates play a vital role, providing critical support and connections for electronic devices. These seemingly simple components are actually the backbone of modern technology and have a profound impact on the performance, reliability and innovation of electronic products.

Package substrates are the core for connecting and supporting electronic components. They provide a critical physical platform for electronic devices. These substrates carry and connect chips, circuits, and other key elements so that they can work together to achieve the normal operation of the device. The quality and design of the packaging substrate directly affect the performance and reliability of the device.

Packaging substrate suppliers play an integral role in the electronics manufacturing ecosystem. They not only provide standardized solutions, but also demonstrate strong capabilities in customized services. The supplier’s diverse product lines enable customers to select the packaging substrate type that best suits their needs, enabling higher levels of performance and innovation.

By partnering with suppliers, companies can obtain professional technical support and customized solutions, allowing them to stay ahead in a highly competitive market. These partnerships are more than just transactions, they are strategic partnerships that provide customers with continued innovation and superior quality.

In this electronic age full of challenges and opportunities, understanding the criticality of packaging substrates and the importance of establishing close relationships with suppliers has become even more urgent. In this article, we’ll delve into the role of packaging substrate suppliers, explore their contributions to the electronics landscape, and how to choose the best partner to drive project success.

Packaging substrate suppliers

The role of packaging substrate suppliers

In the electronics manufacturing ecosystem, packaging substrate suppliers play a vital role. By providing advanced packaging solutions, suppliers are directly involved in the design and manufacturing process of electronic products. Their position in the ecosystem is similar to a hub, connecting raw material providers, manufacturers and end customers to build a collaborative working network.

Suppliers inject new energy into the entire ecosystem through continuous R&D and technological innovation. Their products and services are not just parts and components, but also the engine that drives the entire industrial chain forward. Through investments in new materials, manufacturing processes and designs, packaging substrate suppliers have become key drivers of technological evolution in the electronics field.

The contribution of packaging substrate suppliers goes well beyond providing basic materials. They provide strong support for customers to stand out in the market by deeply understanding their needs and providing customized solutions. Supplier involvement throughout the product life cycle, from the design phase through production and maintenance, contributes an important part to customer success.

By establishing strategic partnerships, suppliers and customers face market challenges together. Their professional knowledge and experience provide customers with reliable support, helping them better understand and respond to industry trends. The supplier’s timely response and excellent service also directly affect the customer’s product delivery and market promotion time, creating more business opportunities for customers.

Under the leadership of packaging substrate suppliers, the electronics manufacturing ecosystem is healthier and more innovative, and customers are more confident in meeting industry challenges.

Package substrate types available

In the field of packaging substrates, suppliers play a key role by providing diversified product lines to meet the needs of different customers. Below are some common packaging substrate types, each with unique applications in the electronics industry.

Different types of packaging substrates

BGA package substrate (Ball Grid Array)

BGA packages are known for their high-density layout and excellent thermal performance.

The chip and substrate are connected through ball solder joints to provide a solid electrical connection.

FCBGA packaging substrate (Flip Chip Ball Grid Array)

FCBGA packaging combines the advantages of Flip Chip technology and BGA packaging.

Achieve compact layout and improve circuit performance by inverting the chip.

Flip Chip packaging substrate

Flip Chip packaging eliminates the need for wires in traditional packaging by directly connecting the chip to the substrate.

Provides a shorter signal path and increases signal transmission speed.

Other customization options

The supplier also offers a range of customized packaging substrates to meet specific project needs.

This may include custom selection of special materials, hierarchies, or packaging processes.

As a packaging substrate supplier, diversified product lines are key to meeting various customer needs. The supplier is committed to providing high quality, innovative and customizable solutions to meet the needs of different industries and applications. By having a broad product line, the supplier ensures that customers can select the packaging substrate that best suits their project, thereby advancing the electronics field.

Packaging substrate customization service

In the highly competitive electronics manufacturing industry, the customized service capabilities of packaging substrate suppliers are particularly critical. This is not only a requirement to meet market demand, but also an inevitable choice to provide innovative solutions to customers. Packaging substrate suppliers are committed to providing customers with highly personalized packaging substrate products by deeply understanding their customers’ unique needs and flexibly using advanced technologies.

Technical customization: Packaging substrate suppliers can meet the technical customization needs of different customers through R&D teams with advanced technology. This includes process optimization for special application scenarios, personalized recommendations for material selection, and technological innovations in high-density wiring technology.

Size customization: In response to customers’ special requirements for packaging substrate size, suppliers provide diversified size customization services. Whether it is a small portable device or a large industrial application, we can find the best balance point in the size of the packaging substrate to meet the specific needs of customers.

Hierarchical structure optimization: Customers have different requirements for the hierarchical structure of the packaging substrate. Suppliers carry out optimized design of the hierarchical structure by deeply understanding the customer’s application scenarios to ensure the excellent performance of the packaging substrate in complex electronic systems.

Successful cases are the best proof of customized services. Close collaboration between packaging substrate suppliers and customers often results in excellent project results, creating a win-win situation for both parties. The following is an introduction to some typical cases:

Customer Challenge: An electronic equipment manufacturer faced the challenge of optimizing the size and thermal performance of the packaging substrate. Traditional standard packaging cannot meet their unique product needs.

Customized solutions: Suppliers communicate in depth with customers to understand the special requirements of their products. By adjusting the size of the packaging substrate and optimizing the heat dissipation structure, we finally provide a customized solution that not only meets the customer’s technical needs, but also significantly improves product performance.

Continuous optimization: Cooperation with customers does not end with project completion, but is a process of continuous optimization. Suppliers have established long-term strategic partnerships with customers and continuously improve and adapt packaging substrates to adapt to the continuous evolution of markets and technologies.

In these cases, suppliers achieved both technical and commercial breakthroughs by fully understanding customer needs and flexibly using customized services.

Choose the best packaging substrate supplier

When selecting a packaging substrate supplier, critical decisions can directly impact the success of your project. Here are some tips and considerations, and why building strategic partnerships with suppliers is crucial.

Technical capabilities: Ensure that the supplier has advanced technical capabilities and can provide packaging substrates that meet your project needs. Carefully evaluate its R&D capabilities, history of innovation, and whether it continues to invest in new technologies.

Product Quality: Review your supplier’s product quality control standards and certifications. Quality packaging substrates are critical to the performance and reliability of electronic devices.

Customized services: If your project requires special customization, choose a supplier that can provide flexible solutions. A supplier that can adapt to different project needs will give you more room for innovation.

Production Capacity and Delivery Time: Understand your supplier’s production scale and delivery capabilities to ensure they can meet your project’s timeline.

Cost-effectiveness: Comprehensive consideration of the balance between product quality and cost. It’s not just about low prices, it’s also about ensuring that the resulting packaging substrate has high performance and long-term reliability.

Collaboration and communication: Establishing close working relationships with suppliers allows for better communication and coordination. This will help resolve issues quickly and improve the overall efficiency of the project.

Shared Goals: Ensure the vendor has a deep understanding of your project and business goals. This helps ensure that both parties are working towards a common goal throughout the project.

Technical support and innovative cooperation: Establishing strategic partnerships with suppliers can make it easier to obtain technical support and participate in innovative cooperation. Vendors may be able to provide you with earlier technical insights and solutions.

Stable supply chain: Strategic partnerships help create a more stable and reliable supply chain. During market fluctuations, this relationship will ensure you continue to have access to the packaging substrates you need.

When selecting a packaging substrate supplier, considering the above suggestions and considerations, as well as the value of establishing strategic partnerships with suppliers, will provide a more secure foundation for your project.

Future trends for packaging substrate suppliers

As technology advances swiftly, the significance of packaging substrate suppliers in electronic manufacturing is poised to intensify. Future trends are not merely set to reshape suppliers’ business models; they will exert a profound influence on the entire electronics industry.

In an era where electronic products are progressively intricate and miniaturized, the role of packaging substrate suppliers will ascend to unprecedented importance. No longer confined to being mere component providers, these suppliers are poised to assume leadership roles in design, innovation, and sustainability. The evolving landscape will see them collaborating closely with customers, delving into their needs, and offering increasingly inventive solutions to meet the demands of a rapidly evolving electronic ecosystem.

Future suppliers will be more involved in the early design stages of products to ensure optimal performance and adaptability of packaging substrates. They will form strategic partnerships with manufacturers to jointly address emerging technologies and market trends. This deep integration will drive closer and more efficient cooperation throughout the supply chain.

In the future, packaging substrate suppliers will pay more attention to sustainability and environmentally friendly practices. Faced with the growing e-waste problem, suppliers will strive to adopt reusable materials and production processes to reduce adverse environmental impacts. This sustainability practice not only aligns with global green initiatives but also helps improve the supplier’s corporate social responsibility profile.

Innovation will also be the core competitiveness of future suppliers. As emerging technologies continue to emerge, such as 5G communications, artificial intelligence and the Internet of Things, suppliers need to constantly adjust their technical capabilities to meet the changing market and the increasingly demanding needs of customers. The use of new materials, advanced manufacturing processes and highly integrated solutions will become the key for suppliers to maintain a competitive advantage.

In this ever-evolving industry, only those suppliers that can continue to innovate and continue to drive sustainable practices will be successful in the future. Therefore, choosing to establish a cooperative relationship with such a supplier will become a key step for an enterprise to succeed in the field of electronics manufacturing. This will not only help ensure product quality and performance, but will also drive the entire electronics field toward a more sustainable and innovative direction.

Professional Flip-Chip Packaging Substrate Supplier

Professional Flip-Chip Packaging Substrate Supplier